Saggar discharging machine with turnover function

A technology of unloading machine and motor reducer, which is applied in the direction of conveyor objects, conveyor control devices, emptying containers, etc., can solve the problems of reducing the service life of the sagger, cracks or breaks of the sagger body, and achieve the goal of eliminating shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

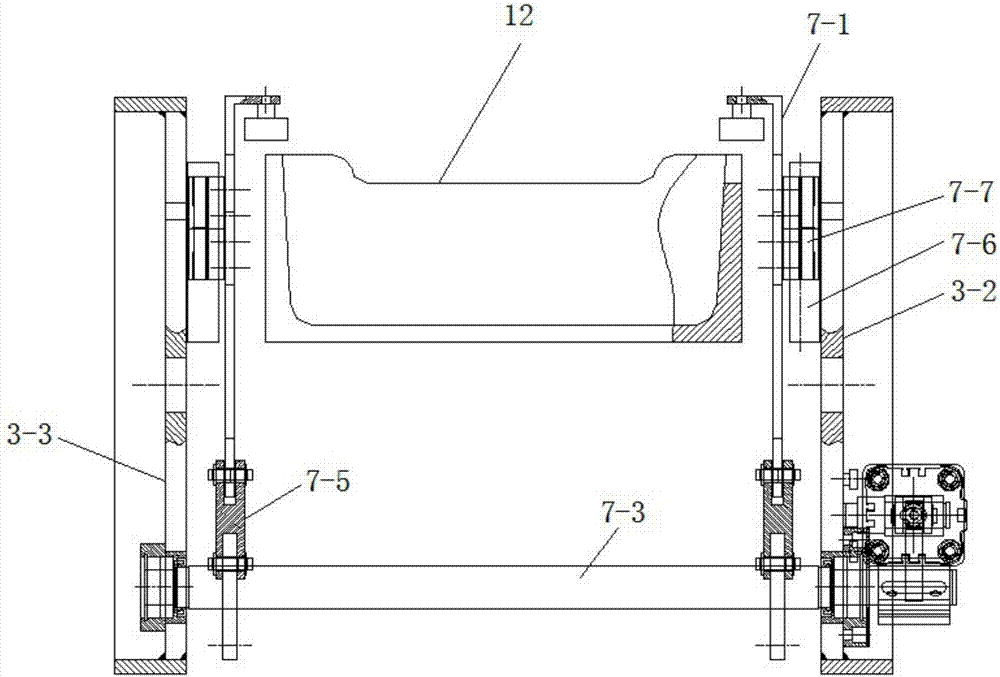

[0037] The inventor of the present application analyzed the current bowl turning machine and found that the reason why the driven roller rubs against the bottom of the sagger is that the driving roller in the roller group on the turning mechanism is located at the center of rotation, and the driving roller and the motor driving the driving roller are decelerated. The machine does not rotate with the overturning mechanism, so when the overturning mechanism overturns, the position of the driven roller changes continuously on the circle centered on the driving roller, and because the driving roller is driven by a chain, the driven roller follows Reverse rotation is generated, thereby rubbing the bottom of the sagger, causing the sagger to shake during the rotation process, and finally causing the sagger body to crack or break.

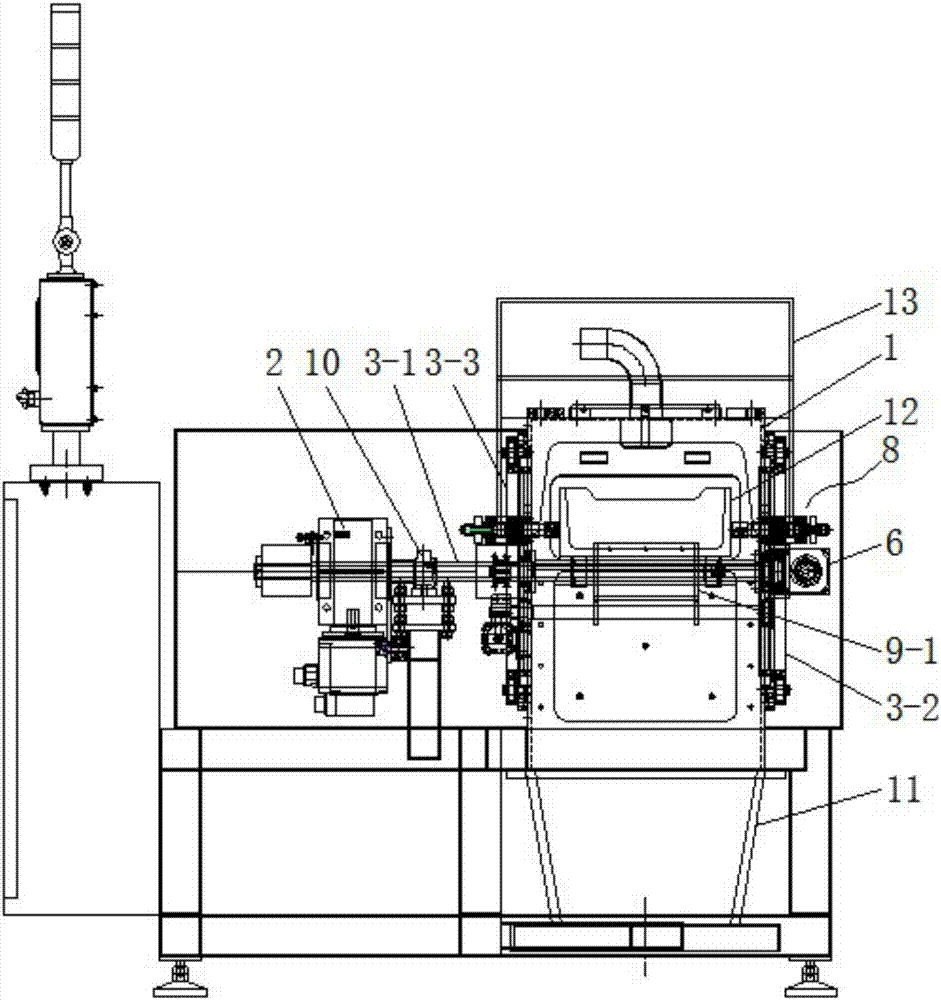

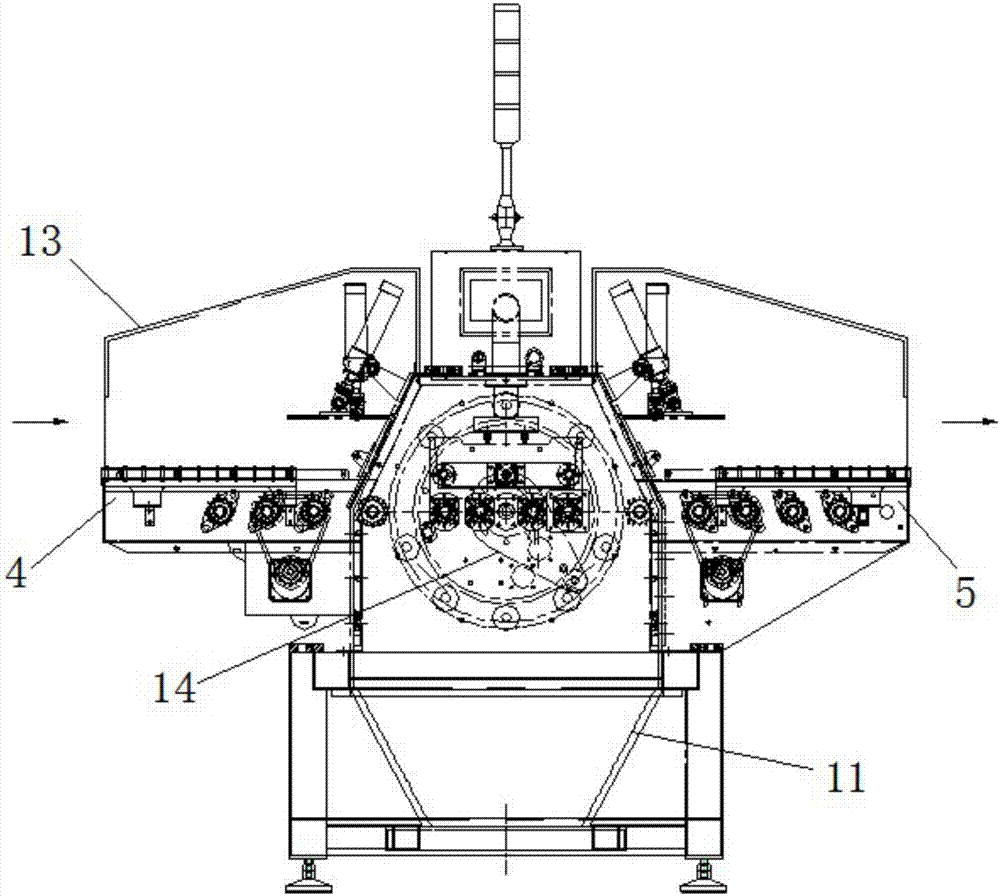

[0038] The invention discloses a bowl dumping machine, such as Figure 1-6 As shown, it includes a bracket 1, a main drive motor reducer 2, a rotating bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com