Processing method of morinda citrifolia ferment

A technology of noni fruit enzyme and processing method, which is applied in the field of food processing, can solve the problems of low nutrient content and poor taste of noni enzyme, and achieve the effects of increasing content, retaining active ingredients, and preventing reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

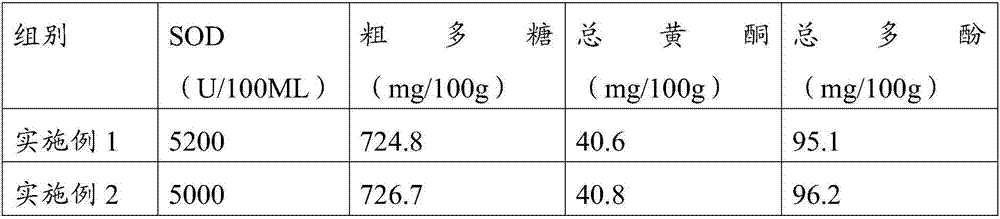

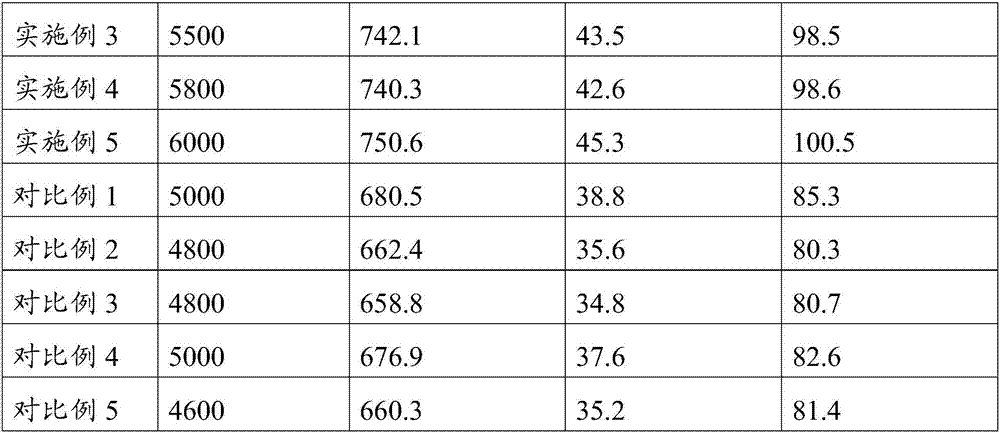

Examples

Embodiment 1

[0025] A processing method of Noni fruit enzyme, comprising the following steps:

[0026] (1) Material selection and processing: fresh noni fruit is washed, chopped and drained, soaked in fresh noni juice for 2 days, beaten, and filtered to obtain a slurry.

[0027] (2) Enzymolysis: the slurry is added with compound enzyme for enzymolysis to obtain the initial solution. The compound enzyme is pectinase and cellulase, the enzymolysis time is 15min, and the enzymolysis temperature is 25°C. The weight ratio of enzymes is 4:1.

[0028] (3) Fermentation for the first time: Inoculate lactic acid bacteria with 1% of the weight of the initial liquid into the initial liquid, and carry out sealed fermentation at a temperature of 25° C. for 45 days to obtain a primary fermentation liquid.

[0029] (4) second fermentation: inoculate 0.1% saccharomycetes of primary fermentation liquid weight in primary fermentation liquid, add sugar, carry out sealed fermentation at temperature 30 ℃ for 3...

Embodiment 2

[0034] A processing method of Noni fruit enzyme, comprising the following steps:

[0035] (1) Material selection and processing: fresh noni fruit is washed, chopped and drained, soaked in fresh noni juice for 2 to 3 days, beaten, and filtered to obtain a slurry.

[0036] (2) Enzymolysis: the slurry is added with a compound enzyme for enzymolysis to obtain the first liquid, the compound enzyme is pectinase and cellulase, the enzymolysis time is 25min, and the enzymolysis temperature is 30°C. The weight ratio of enzymes is 6:2.

[0037] (3) Fermentation for the first time: Inoculate the lactic acid bacteria of 3% of the weight of the initial liquid into the initial liquid, and carry out sealed fermentation at a temperature of 30°C for 60 days to obtain a primary fermentation liquid.

[0038] (4) Fermentation for the second time: inoculate 2% saccharomycetes of primary fermentation liquid weight in primary fermentation liquid, add sugar, carry out sealed fermentation 45 days at ...

Embodiment 3

[0043] A processing method of Noni fruit enzyme, comprising the following steps:

[0044] (1) Material selection and processing: fresh noni fruit is washed, chopped and drained, soaked in fresh noni juice for 2 days, beaten, and filtered to obtain a slurry.

[0045] (2) Enzymolysis: add the slurry to compound enzymes for enzymolysis to obtain the first liquid, the compound enzymes are pectinase and cellulase, the enzymolysis time is 18min, and the enzymolysis temperature is 26°C. The weight ratio of enzymes is 5:1.

[0046] (3) Fermentation for the first time: inoculate the lactic acid bacteria of 1.5% of the weight of the initial liquid into the initial liquid, and carry out sealed fermentation at a temperature of 26° C. for 50 days to obtain a primary fermentation liquid.

[0047] (4) second fermentation: inoculate 0.5% saccharomycetes of primary fermentation liquid weight in primary fermentation liquid, add sugar, carry out sealed fermentation at temperature 32 ℃ for 35 da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com