Ancient architecture timberwork residual life reliability prediction method suitable for corrosion environment

A technology of corrosive environment and prediction method, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of failure criteria and life discreteness of wooden structures that are not considered, and achieve reasonable life prediction criteria and strong applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings.

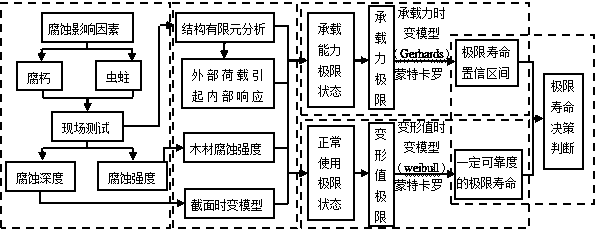

[0053] Such as figure 1 As shown, a method for predicting the remaining life reliability of ancient building wooden structures applicable to corrosive environments of the present invention comprises the following steps:

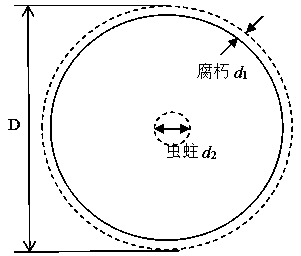

[0054] Step S1: Analyze the material time-varying model under the influence of corrosion according to the material of the active structure; including the material time-varying model under decay and the material time-varying model under moth:

[0055] Based on the verification of ancient wood with a certain age, the formula for the change trend of ancient wood under decay is as follows:

[0056] d 1 = d 0 (1+t / T 0 ) ξ (1)

[0057] In the formula, d 1 is the decay depth of the duration; d 0 is the decay depth at the present stage; t is the duration, and the unit is a (year); T 0 is the historical time, ξ is an index parameter considering the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com