Temporary support-sliding device after tire bursting of automobile

A technology for temporary support and tire blowout, applied in vehicle parts, transportation and packaging, tire parts, etc., can solve problems such as time-consuming, troublesome replacement of spare tires, and unsuitable tires to continue to use, and achieves safe and reliable installation and supporting sliding effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

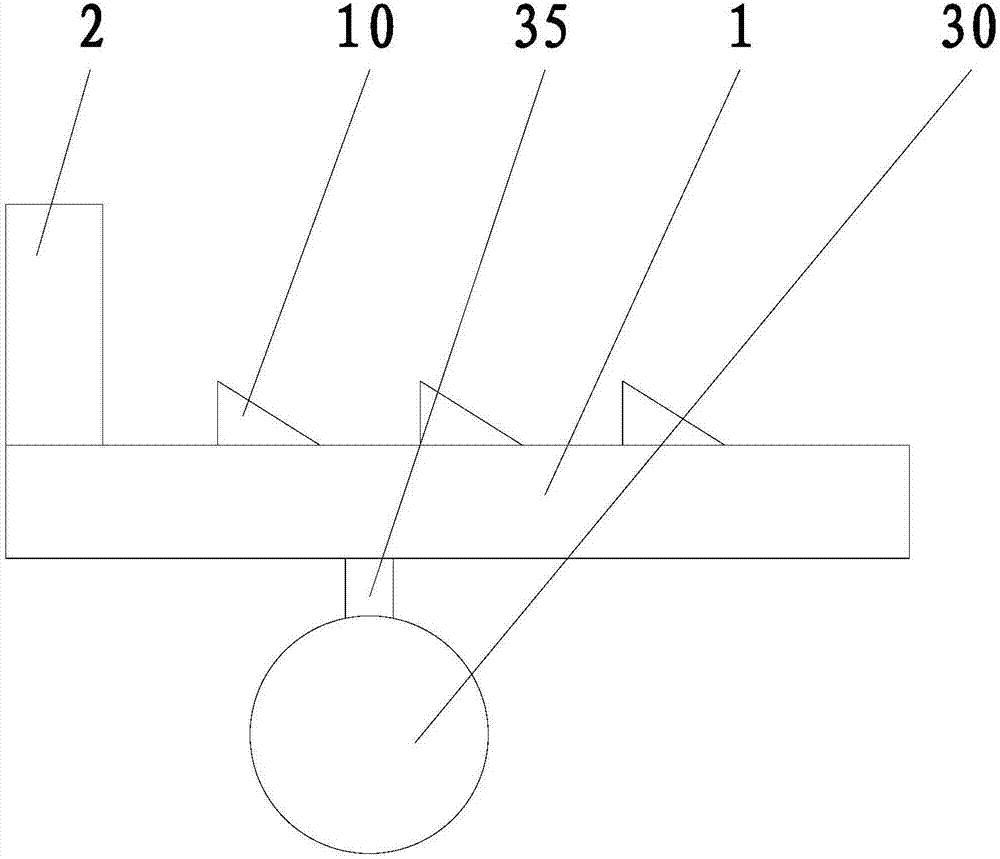

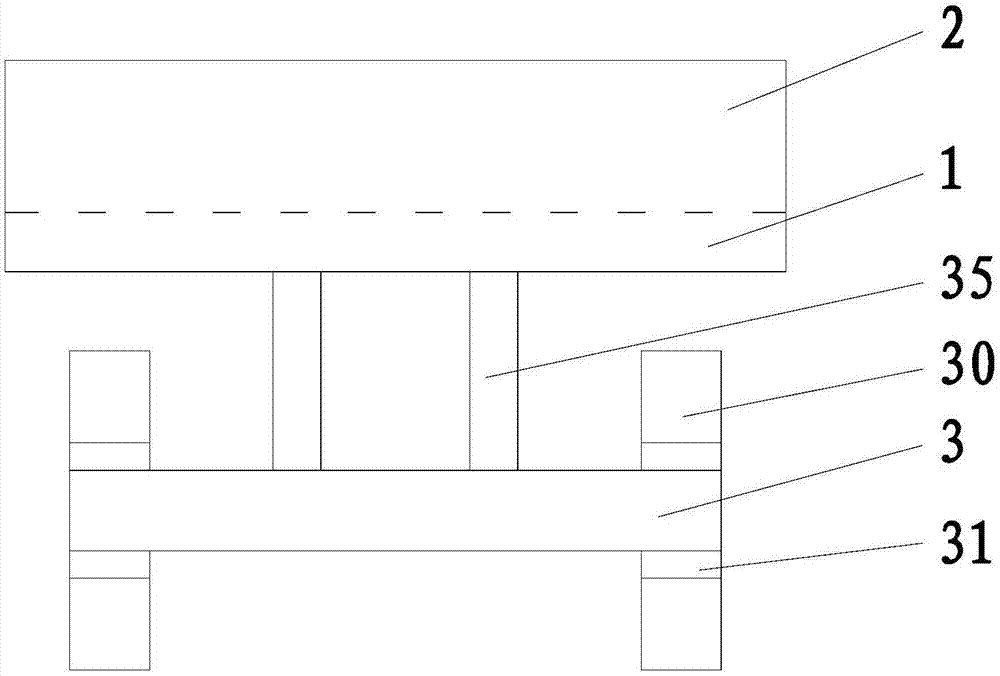

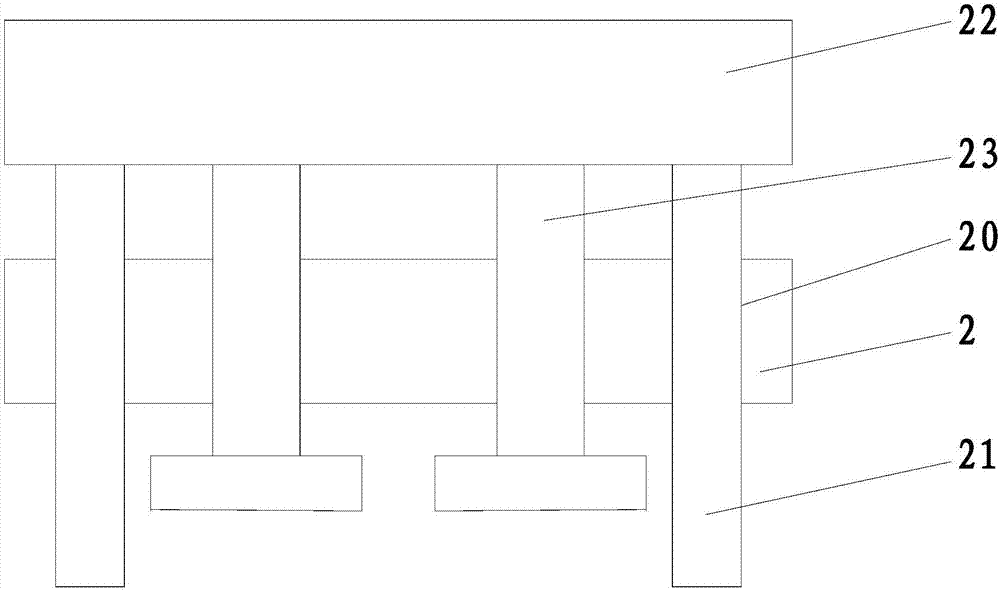

[0014] refer to figure 1 , figure 2 and image 3 , the present invention is a temporary support sliding device after a tire blowout, comprising a support plate 1, a baffle plate 2, an installation shaft 3, a support column 35, and a roller 30, and a baffle plate 2 is fixed on the left side of the upper end surface of the support plate 1 , the baffle plate 2 is perpendicular to the support plate 1, an installation shaft 3 is arranged below the support plate 1, and several support columns 35 are fixed on the installation axis 3, and the top of the support column 35 is fixed on the bottom of the support plate 1, and the installation axis 3 A roller 30 is installed at both ends, and the roller 30 and the installation shaft 3 are fixed by a bearing 31. A number of blocking strips 10 are fixed on the upper end surface of the support plate 1. The blocking strips 10 are parallel to the installation shaft 3, and the blocking strips 10 The cross-section of the barrier strip 10 is a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com