Apparatus and method for accurately positioning hydraulic fore-support moving route

A hydraulic support and accurate positioning technology, applied in the direction of mine roof support, earthwork drilling, mining equipment, etc., can solve problems such as affecting coal mining efficiency, coal mine safety production, inability to achieve advance hydraulic support movement, and movement deflection, etc. Improve the efficiency of coal mining and the safe production of coal mines, the structure is simple and reliable, and the effect of preventing the base from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

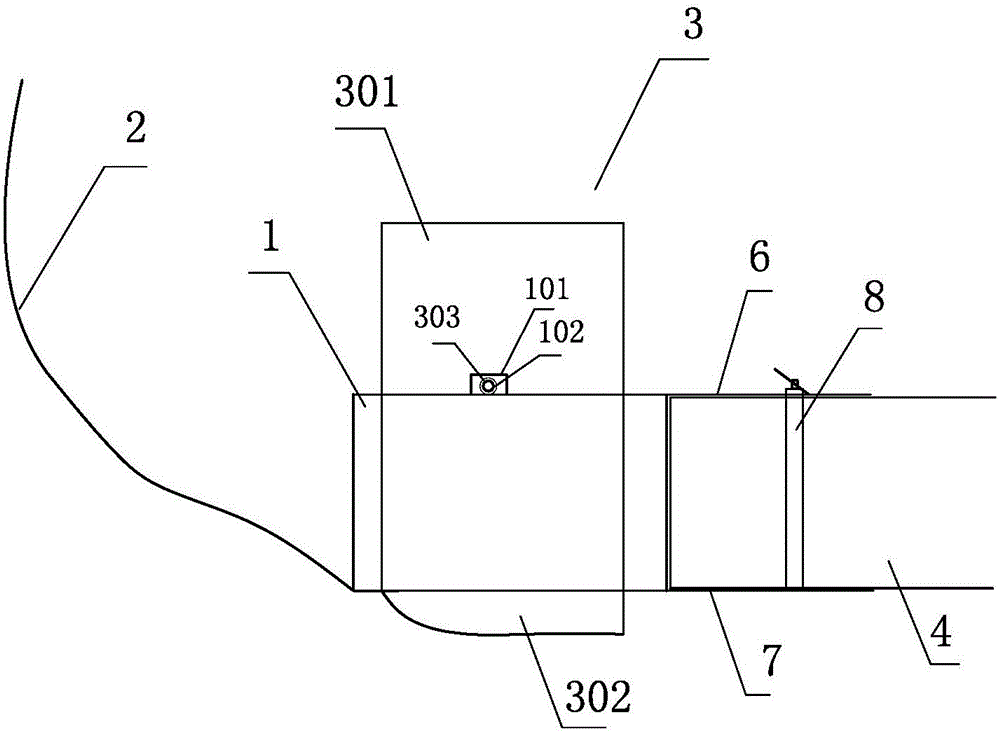

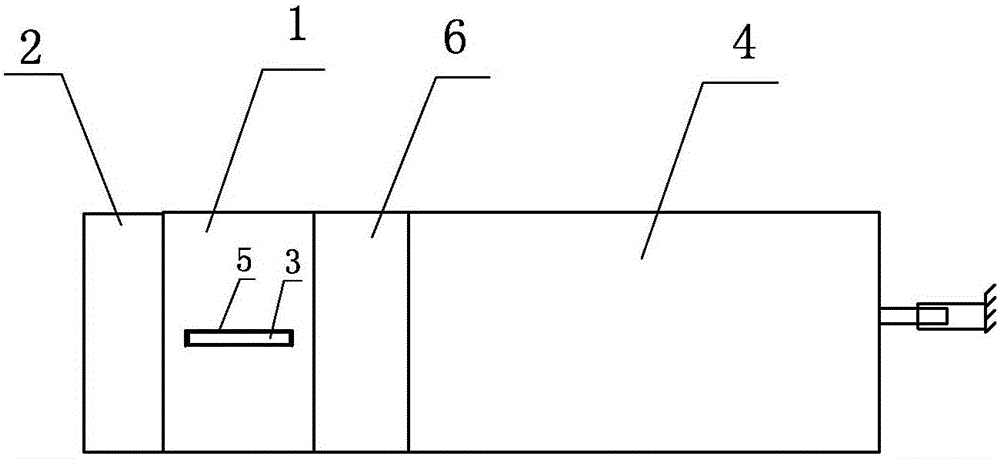

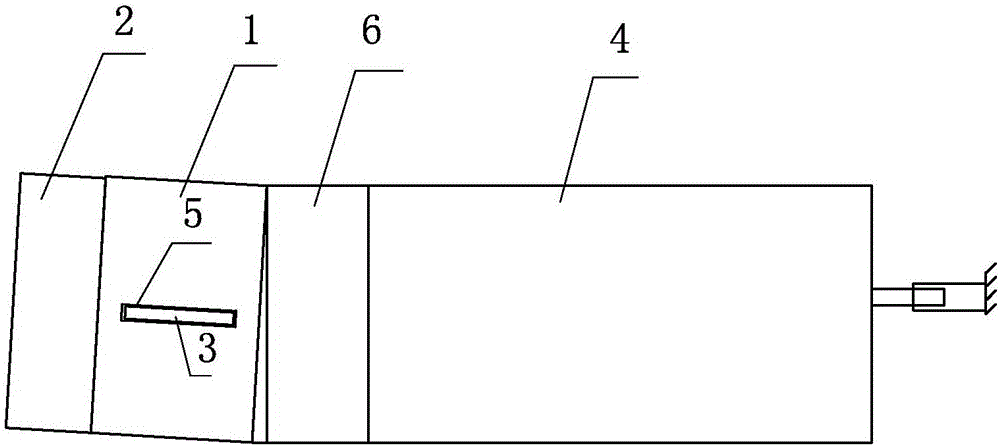

[0029] Such as Figure 1 ~ Figure 3 As shown, a device for accurately positioning the moving path of the advanced hydraulic support includes a load-bearing block 1, an anti-drilling baffle 2 and a guide plate 3. The load-bearing block 1 is connected to the front end of the base of the advanced hydraulic support 4, and the load-bearing block 1 The middle part is provided with a fixed groove 5 that runs through up and down, and a guide plate 3 is arranged in the fixed groove 5. The anti-drilling bottom baffle plate 2 is an arc-shaped plate, and its lower end is connected with the front end of the bottom of the load-bearing block 1. The middle part of the arc-shaped plate faces The lower part of the advancing direction of the leading hydraulic support 4 protrudes.

[0030] The guide plate 3 comprises a first fixed plate 301 and a cutting portion 302 connected to the bottom of the first fixed plate 301, a second fixed plate 101 is respectively arranged on both sides of the longitu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com