Diesel engine shaft system torsional-vibration calculating method

A shafting torsional vibration and calculation method technology, which is applied in calculation, special data processing applications, instruments, etc., can solve the problem that the coupling relationship between the auxiliary mechanism and the crankshaft shafting has not been paid enough attention, and meets the calculation requirements of the shafting torsional vibration , Response calculation is accurate, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below in conjunction with example.

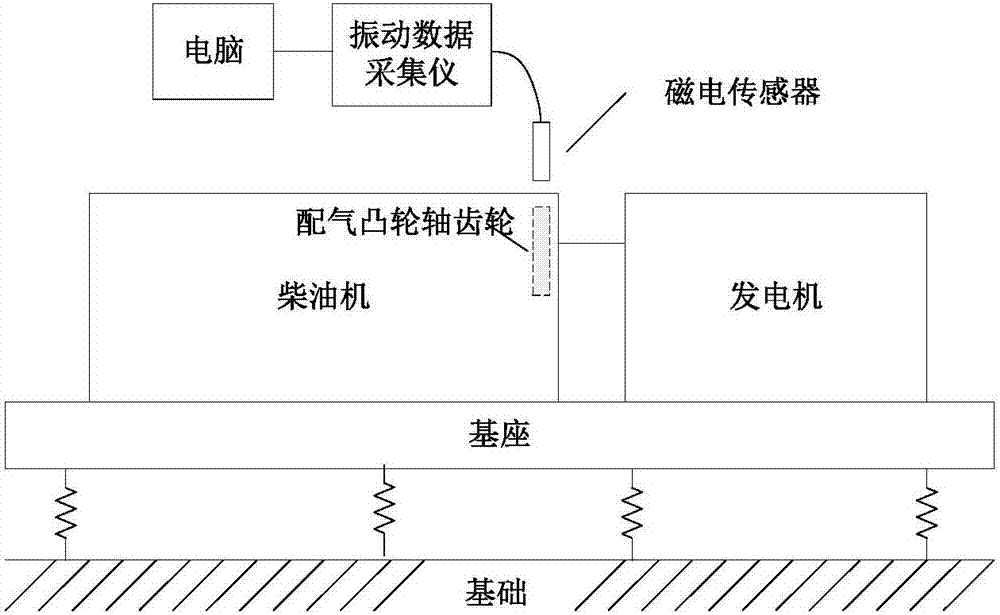

[0044] A marine diesel generator set is mainly composed of MAN 5L21 / 31 diesel engine, generator and common base, with a rated speed of 900r / min and a rated power of 1000kW.

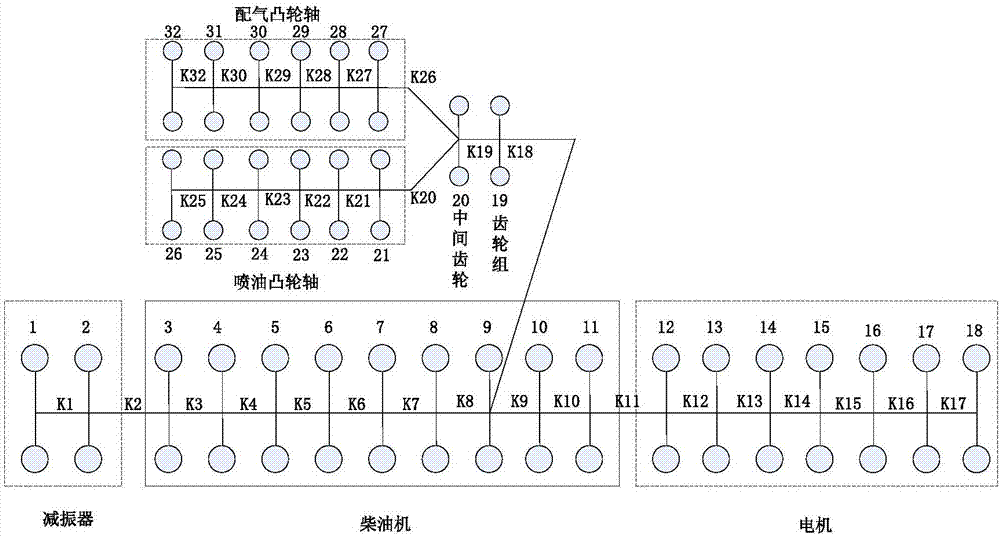

[0045] The crankshaft and camshaft are simplified equivalently, and the camshaft includes the gas distribution camshaft and the fuel injection camshaft. According to the torsional vibration calculation parameters of the diesel engine shaft system provided by the manufacturer, the inertia matrix, stiffness matrix and damping matrix are calculated by the lumped parameter method.

[0046] Integrate the equivalent models of the crankshaft and camshaft, and establish the equivalent model of the diesel engine shaft including the crankshaft and its subsidiary mechanisms, see figure 1 .

[0047] The gas excitation torque generated by the gas pressure change in the diesel engine cylinder is:

[0048]

[0049] In the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com