A high-speed optical cable sz twisting and binding machine with low turnover number

A yarn binding machine and optical cable technology, which is applied in the field of optical fiber equipment, can solve the problems that the rotation speed cannot be increased at the same time, the number of twists and turns of SZ stranding, the production speed cannot be increased, and the motor commutation is difficult, so as to improve the stranding quality and reduce the steering Load, the effect of reducing operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the drawings and embodiments.

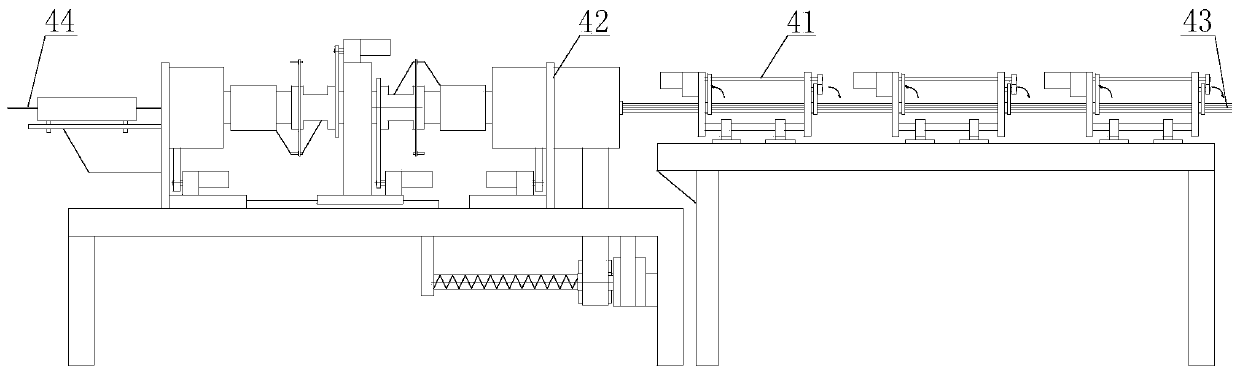

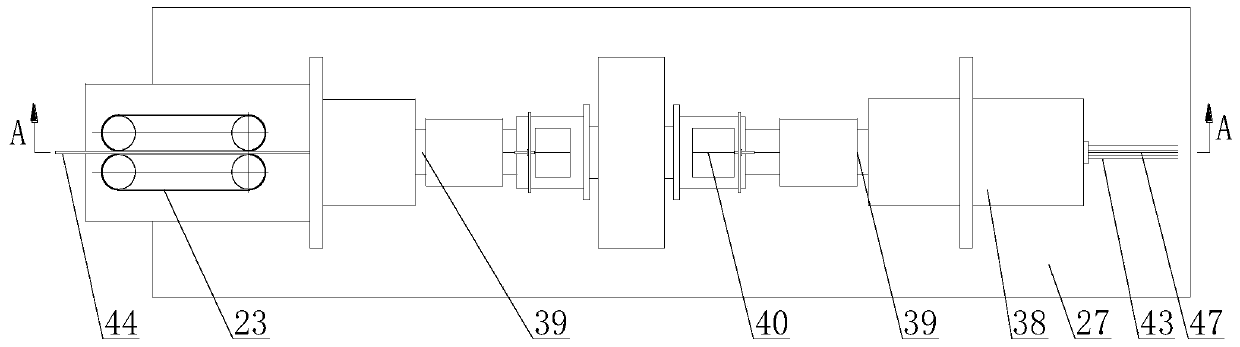

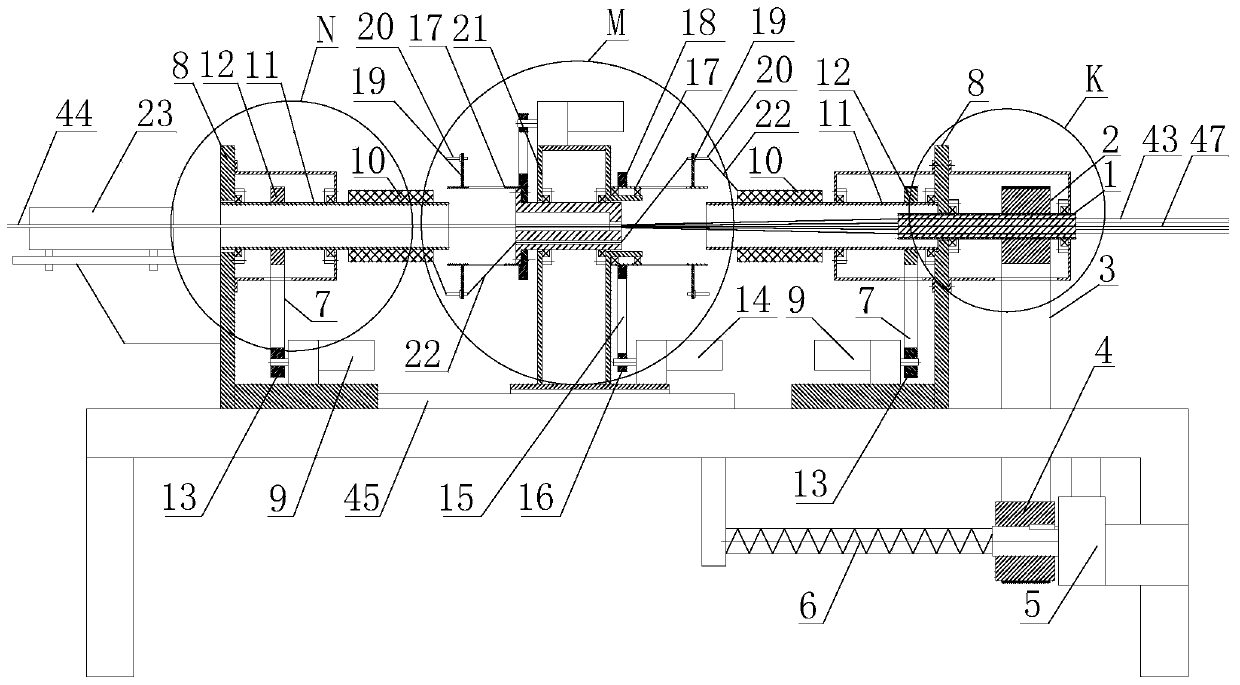

[0035] Refer to Figure 1~Figure 10 As shown, the high-speed optical cable SZ stranding and binding machine with low turnover number in an embodiment provided by the present invention includes a transitional stranding component 41 and a stranding binding component 42. The output end of the transitional stranding component 41 and the twisting The input ends of the binding yarn component 42 are butted, and the multiple optical fiber sleeves 43 are pre-twisted through the transition stranding component 41 to avoid sudden large-angle twisting to damage the optical fiber, and then the twisting yarn component 42 forms an optical cable. Core 44;

[0036] Among them, the twisting and binding component 42 includes a first frame 37. A twisting device 38, a winding device, and a passive anti-twisting belt 23 are sequentially arranged on the first frame 37 along the conveying dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com