Method for high-precision measurement of sphericity of micro-spherical probe of nanometer three-coordinate measuring machine

A three-coordinate measuring machine, high-precision technology, applied in point coordinate measurement, electromagnetic measurement device, electric/magnetic contour/curvature measurement, etc., can solve unreliable and unreasonable problems, and achieve small measurement force and high coverage , to ensure the effect of high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will be combined with Figure 4 , taking a nano-coordinate measuring machine (Nano-CMM) microsphere probe 5 with a diameter of about 300 μm used on a nano-coordinate measuring machine as an example, to further introduce the present invention.

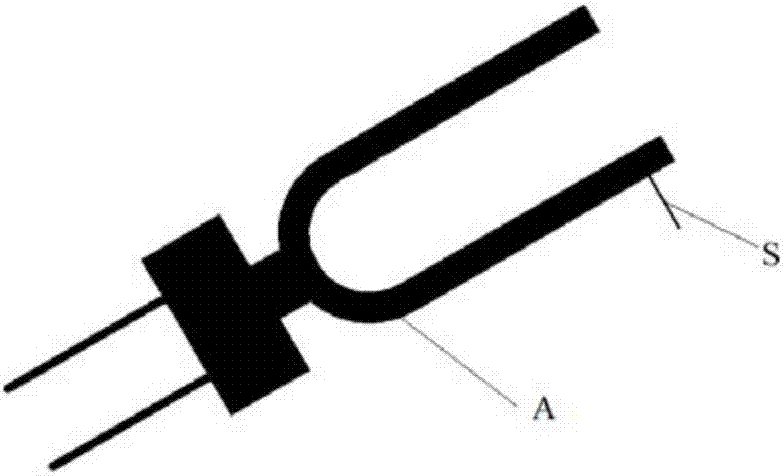

[0028] A method capable of realizing high-precision measurement of the sphericity of a nanometer three-coordinate measuring machine microball probe, comprising the following steps: first, a tungsten probe S with a large aspect ratio and a sharp tip is fixed on a quartz tuning fork resonant sensor A to construct a Tuning fork scanning probe probe with nanoscale resolution and large aspect ratio. Schematic diagram of the structure of the tuning fork scanning probe probe figure 1 .

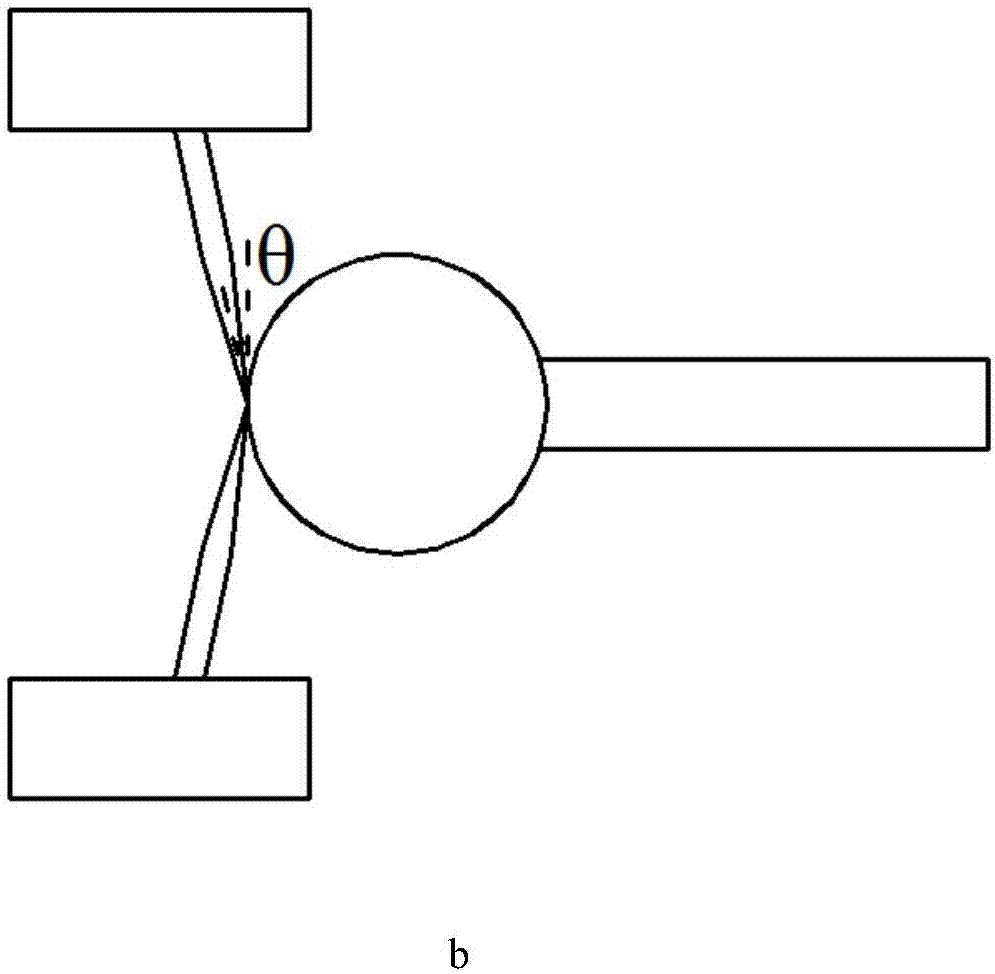

[0029] Place the two tuning fork scanning probe probes in a differential manner, and construct a differential scanning measurement system with the aid of precision micro-motion stages 1 and 2 for measuring their motion displacement; befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com