Quick singeing equipment

A kind of equipment and rapid technology, applied in singeing, textile and paper making, fabric surface trimming, etc., can solve problems such as incomplete singeing and easy damage to fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

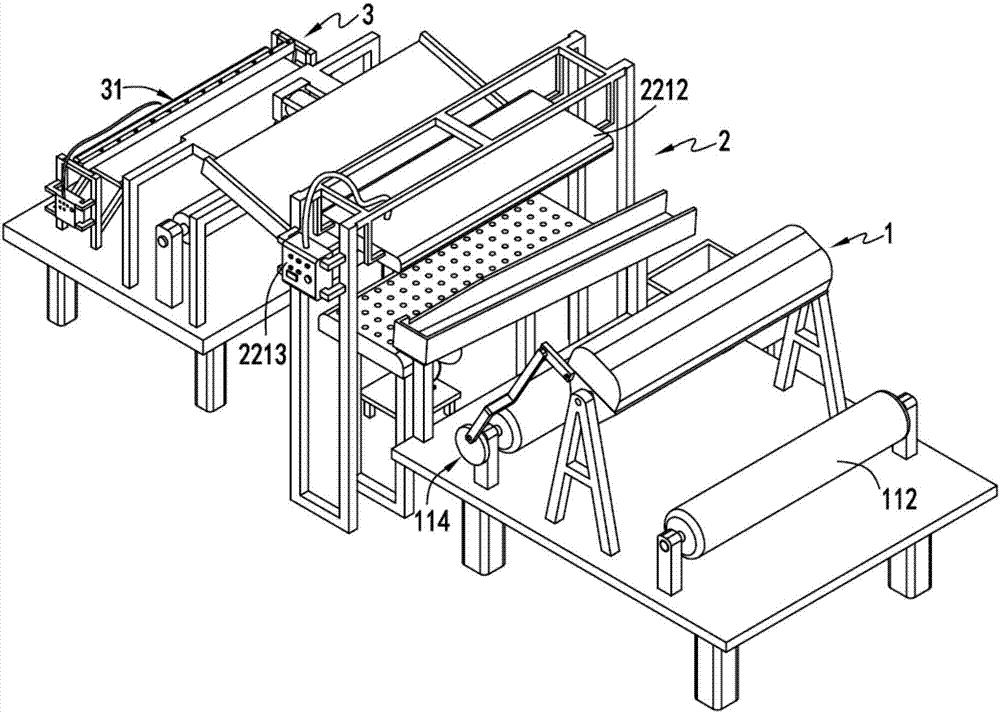

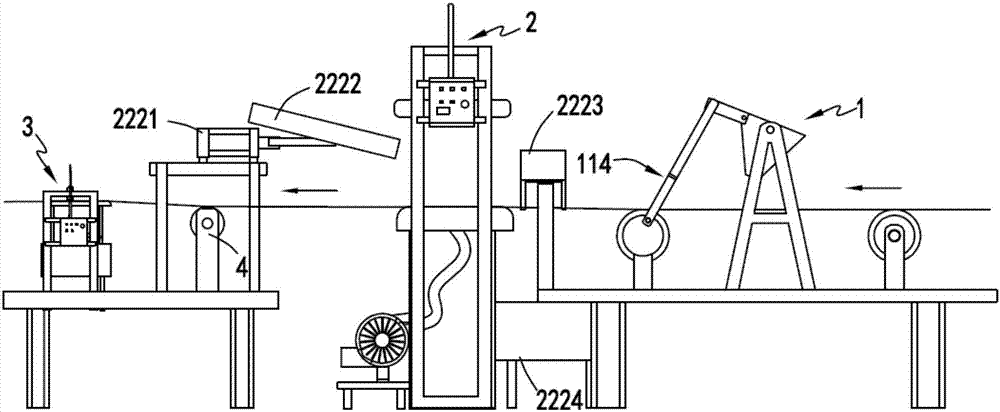

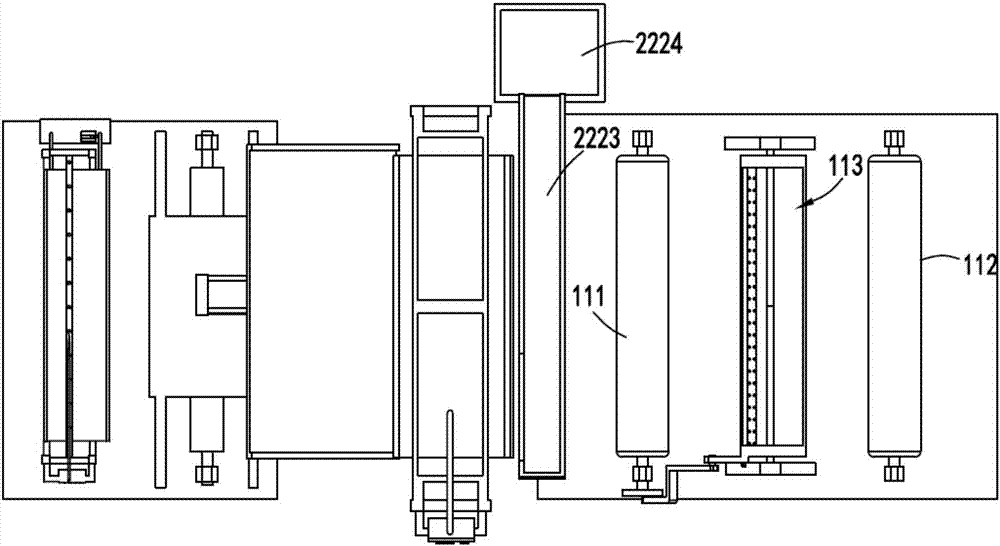

[0036] figure 1 It is a schematic diagram of the structure of the fast singeing equipment, figure 2 It is a schematic diagram of the front view of the fast singeing equipment, image 3 It is a schematic diagram of the top view of the fast singeing equipment, Figure 4 It is a schematic diagram of the structure of the spreading mechanism, Figure 5 Schematic diagram of the structure of the singeing mechanism, Figure 6 It is a schematic diagram of the structure of the negative pressure adsorption mechanism, Figure 7 It is a schematic diagram of the structure of the magnetic combing mechanism, Figure 8 is a schematic diagram of the cooling mechanism, Figure 9 It is an enlarged schematic diagram of part of the structure of the spreading mechanism. like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, a fast singeing device includes an upper metal particle part 1, and the upper metal particle par...

Embodiment 2

[0052] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the electromagnetic adsorption device 221 includes a fixed frame 2211, a magnetic suction plate 2212 fixed on the fixed frame 2211, and a magnetic suction plate 2212 arranged on one side of the fixed frame 2211 for controlling the magnetic force. A control unit 2213 for generating magnetic force by the suction plate 2212;

[0053] The collection device 222 includes a horizontal push cylinder 2221, a material receiving plate 2222 arranged at the end of the telescopic rod of the horizontal push cylinder 2221, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com