Method for making two-color single jacquard warp-knitted fabric and the warp-knitted fabric

A production method and technology of woven fabrics, which are applied in the weaving method of fabrics and the field of fabrics, can solve problems such as the difficulty of clearly reflecting two-color effects, and achieve a strong visual three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention will be further described below in conjunction with specific embodiments:

[0023] The preparation method of the two-color single jacquard warp knitted fabric provided by the present embodiment comprises the following steps:

[0024] S1, preparing for weaving, designing the pattern of the fabric and the distribution area of the two colors in the pattern on the computer. The specific pattern can be determined according to actual needs, which is not the focus of this embodiment, and will not be described in detail here.

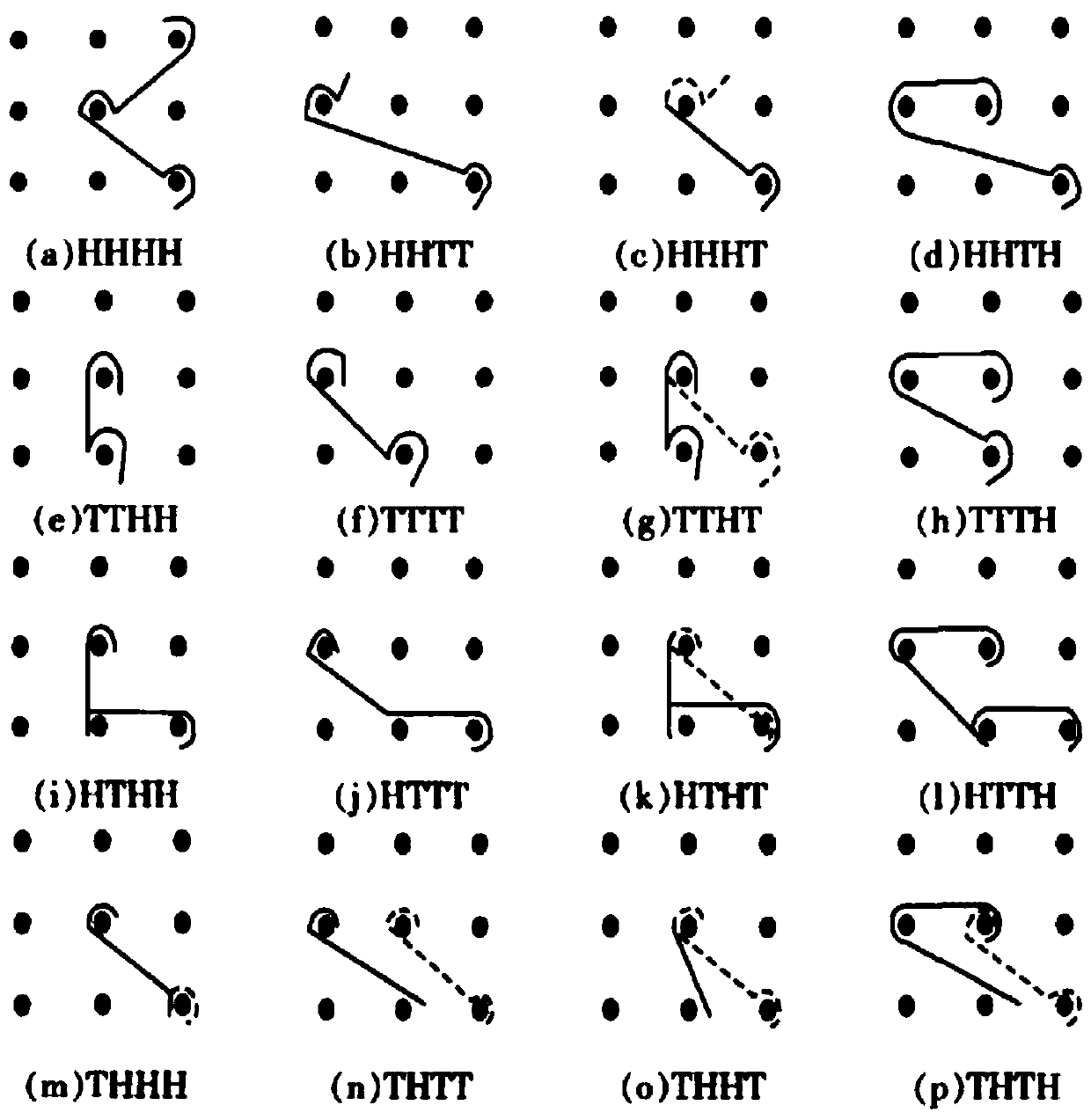

[0025] S2, bar configuration, select a double-needle bed warp knitting machine with more than six bars, wherein the six bars are B1, B2, B3, B4, B5, and B6 according to their arrangement positions. Among the combs, B2 and B3 together form a separate jacquard comb, and both adopt half-gauge configuration.

[0026] Afterwards, each bar is threaded. Among them, B1, B4, B5, and B6 are all threaded in a full-threaded manner, and B2 and B3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com