A liquid-liquid doped rare earth oxide copper-based composite material and its preparation method

A technology of copper-based composite materials and rare earth oxides, which is applied in the field of liquid-liquid doped rare earth oxide copper-based composite materials and its preparation, can solve the problems of rare earth oxide dispersion-strengthened copper alloys that do not meet the requirements of deep processing of deformation and particle/matrix interface detachment. Sticking, accelerating the failure process and other problems, to avoid further grain growth, not easy to debond at the interface, not easy to break the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

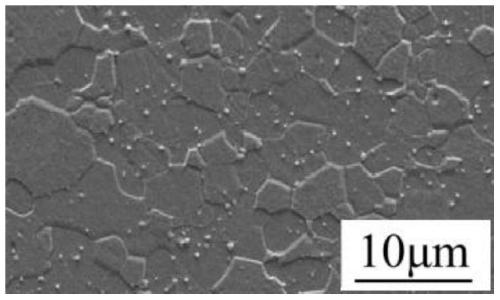

Image

Examples

Embodiment 1

[0029] A liquid-liquid doped rare earth oxide copper-based composite material, comprising the following components in weight percentage: 0.5% La 2 o 3 , and the balance is copper and unavoidable impurities.

[0030] Rare earth oxide (La 2 o 3 ) is 0.5% by mass.

[0031] 1) dissolving rare earth lanthanum nitrate in water, mixing with ammonium cuprate solution, adjusting the pH value to 8, and obtaining a mixture containing rare earth lanthanum ammonium cuprate sol after stirring evenly;

[0032] 2) Add citric acid to the mixture of rare earth-containing lanthanum ammonium cuprate sol prepared in step 1) for hydrothermal synthesis reaction at a temperature of 150°C, filter in alcohol and deionized water after cooling, and vacuum dry at 180°C Dry in the oven for 10 hours to obtain rare earth ammonium lanthanum cuprate powder;

[0033] 3) Calcining the rare earth ammonium lanthanum cuprate powder obtained in step 2) at 560° C. for 6 hours to obtain rare earth lanthanum doped...

Embodiment 2

[0039] A liquid-liquid doped rare earth oxide copper-based composite material, comprising the following components in weight percentage: 1.3% Ce 2 o 3 , and the balance is copper and unavoidable impurities.

[0040] Rare earth oxide (Ce 2 o 3 ) is 1.3% by mass.

[0041] 1) dissolving rare earth cerium nitrate in water, mixing with ammonium cuprate solution, adjusting the pH value to 8.5, and obtaining a mixture containing rare earth cerium ammonium cuprate sol after stirring evenly;

[0042] 2) Add citric acid to the mixture of ammonium cuprate sol containing rare earth cerium prepared in step 1) to carry out hydrothermal synthesis reaction at a temperature of 170°C, filter in alcohol and deionized water after cooling, and vacuum dry at 200°C Dry in the oven for 10 hours to obtain rare earth ammonium cerium cuprate powder;

[0043] 3) Calcining the rare earth ammonium cerium cuprate powder obtained in step 2) at 580° C. for 6 hours to obtain rare earth cerium-doped copper...

Embodiment 3

[0049] A liquid-liquid doped rare earth oxide copper-based composite material, comprising the following components in weight percentage: 2.5% Y 2 o 3 , and the balance is copper and unavoidable impurities.

[0050] Rare earth oxide (Y 2 o 3 ) is 2.5% by mass.

[0051] 1) dissolving rare earth yttrium nitrate in water, mixing with ammonium cuprate solution, adjusting the pH value to 8.3, and obtaining a mixture containing rare earth yttrium ammonium cuprate sol after stirring evenly;

[0052] 2) Add citric acid to the mixture of rare earth-containing ammonium yttrium cuprate sol prepared in step 1) to carry out hydrothermal synthesis reaction at a temperature of 180°C, filter in alcohol and deionized water after cooling, and vacuum-dry at 200°C Dry in the oven for 8 hours to obtain rare earth ammonium yttrium cuprate powder;

[0053] 3) Calcining the rare earth ammonium yttrium cuprate powder obtained in step 2) at 600° C. for 6 hours to obtain rare earth yttrium-doped cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com