Transport vehicle facilitating wheel stack

A technology for transporting vehicles and wheels, which is applied to the field of transporting vehicles that facilitate stacking of wheels, can solve the problem that the transporting vehicles cannot effectively meet the needs of users, and achieve the effects of convenient placement, easy loading, unloading and fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

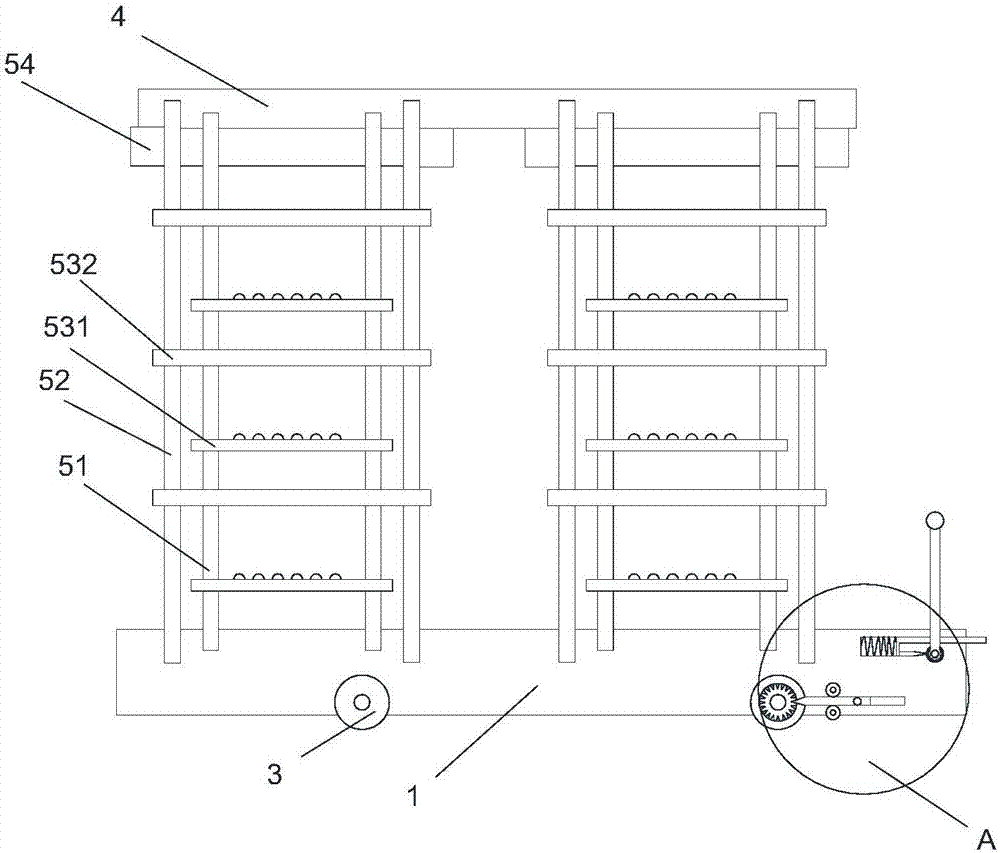

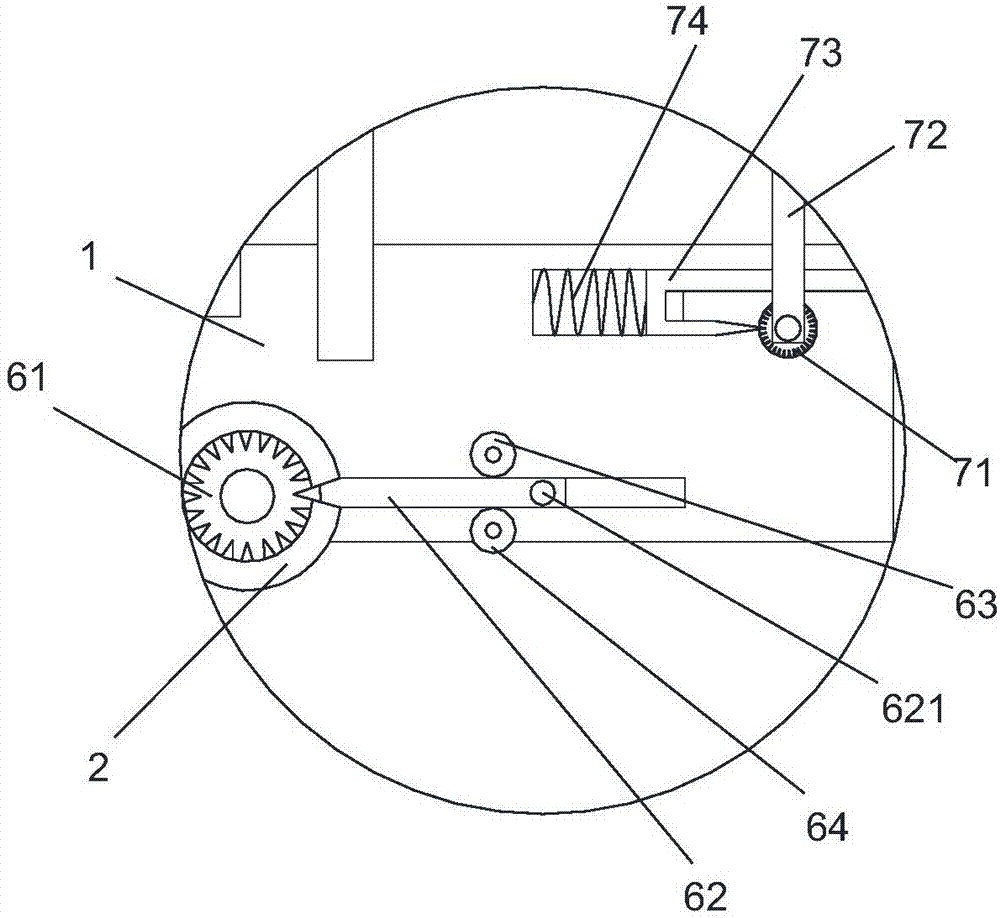

[0017] refer to figure 1 and figure 2 As shown, the present invention proposes a transport vehicle that is convenient for wheel stacking, including a carrier 1, a plurality of first rollers 2, a plurality of second rollers 3, a top positioning frame 4 and a plurality of wheel positioning mechanisms;

[0018] The first roller 2 and the second roller 3 are all installed on the bottom of the carrier 1; the wheel positioning mechanism includes a plurality of first installation shafts 51, a plurality of second installation shafts 52 and a plurality of clamping plate groups, the first installation shaft The lower end and the upper end of 51 are respectively connected to the carrier 1 and the top positioning frame 4, the lower end and the upper end of the second installation shaft 52 are respectively rotatably connected to the carrier 1 and the top positioning frame 4, and the clamping plate group includes the loading plate 531 and the clamping plate plate 532, the loading plate 53...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap