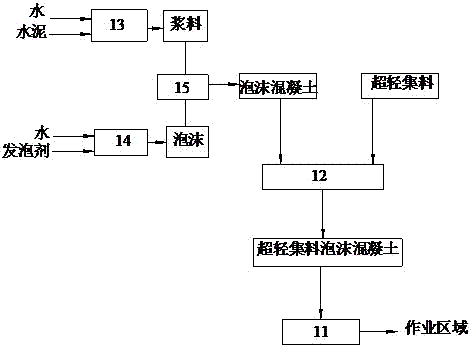

Construction process for super light aggregate foaming concrete

A technology of foam concrete and construction technology, applied in clay preparation equipment, chemical instruments and methods, cement mixing equipment, etc., can solve problems such as uneven mixing, easy floating of ultra-light aggregates, difficulty in wrapping, etc., and improve thermal performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

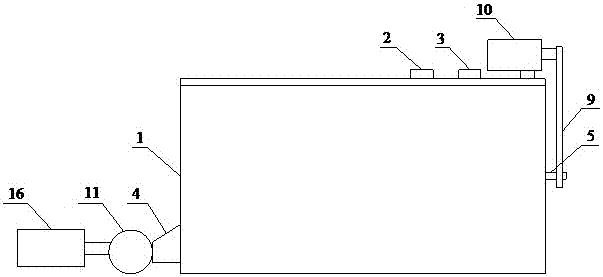

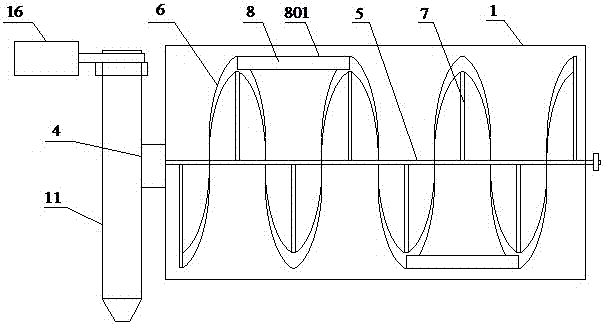

Method used

Image

Examples

Embodiment 2

[0060] refer to Figure 5~Figure 6 , the construction technology of ultra-light aggregate foam concrete described in this embodiment is an improvement on the basis of Example 1, wherein:

[0061] The bottom of the secondary mixer is connected to a supporting frame 17, and a roller 18 is arranged on the bottom of the supporting frame.

[0062]In this way, it can move freely under the action of external force. Compared with the traditional mixer, the flexibility of movement is increased; and on this basis, the bracket can be connected to the front end of the support frame, which is convenient for dragging and moving behind the car.

[0063] Wherein, the corner portion of the support frame is provided with a collar 19, the upper part of the roller is connected with an adjustable rod 20, and the adjustable rod is sleeved in the collar, and a through hole 21 is arranged on the adjustable rod. A pin shaft 22 is inserted into the through hole. This makes it easy to set the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com