Silicone composition

A composition, liquid silicon technology, applied in conductive materials dispersed in non-conductive inorganic materials, materials for heat exchange, conductive coatings, etc., to achieve the effect of inhibiting viscosity rise and inhibiting sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

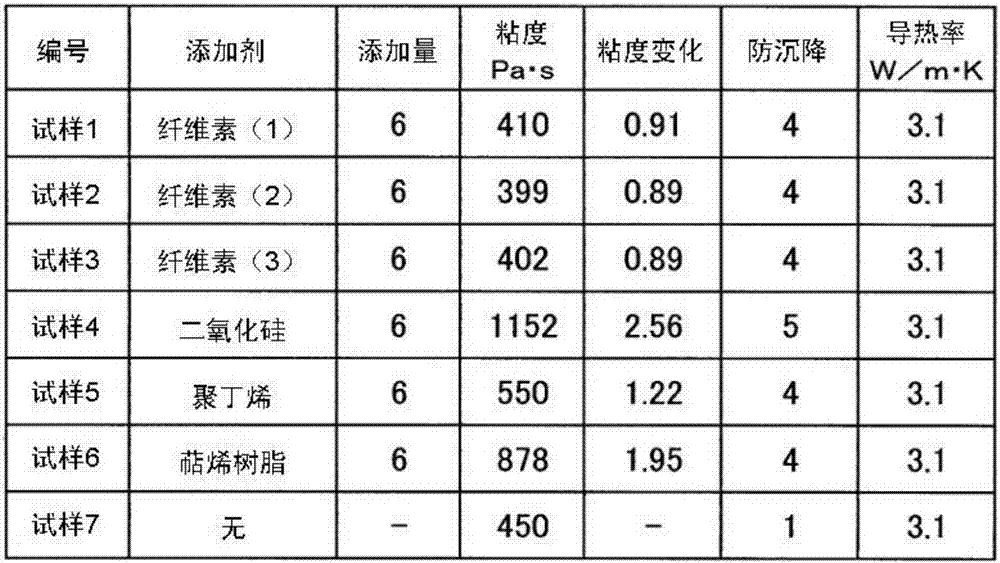

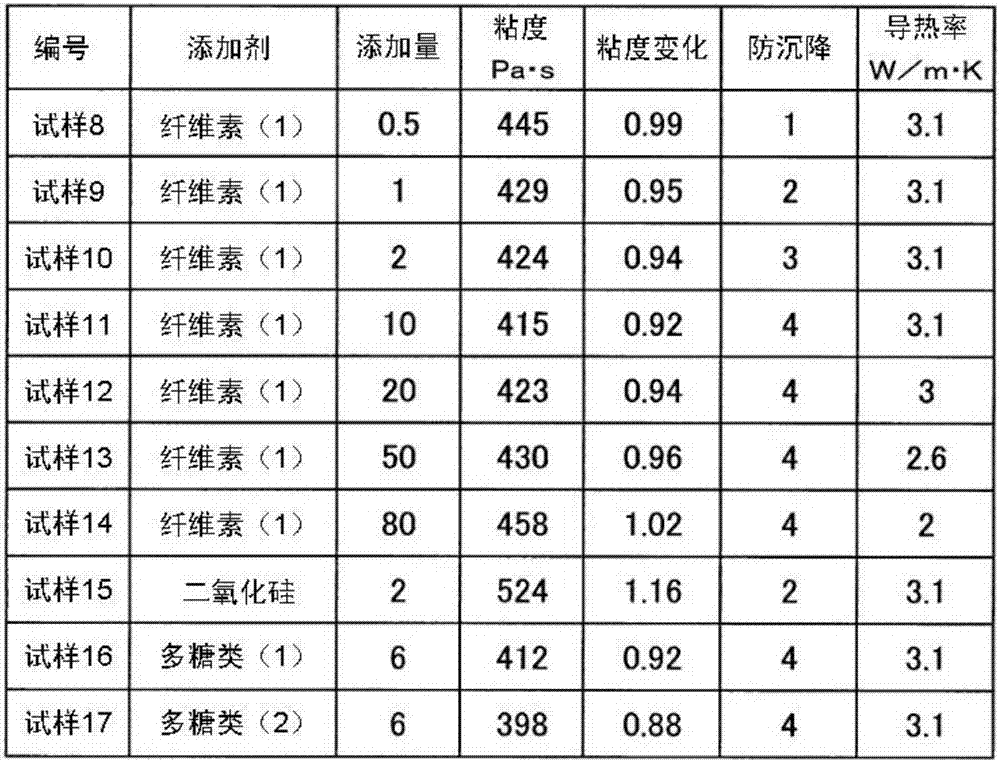

[0045] In this embodiment, a mode in which a thermally conductive filler that imparts thermal conductivity is used as a non-dissolvable function-imparting filler will be described. As far as the thermally conductive silicon composition containing thermally conductive fillers is concerned in liquid silicon, after being arranged between a plurality of heating elements mounted on a substrate and a radiator disposed opposite to the heating element, it can be used as a function of distributing the heating elements. The dissipated heat is transferred to the material that acts as a heat sink.

[0046] The thermally conductive silicon composition contains liquid silicon, a thermally conductive filler (non-dissolvable function-imparting filler), and a non-liquid thickening suppressing anti-sedimentation material.

[0047] Liquid silicon includes both non-curable liquid silicon and curable liquid silicon. When non-curable liquid silicon is used, the thermally conductive silicon compositi...

no. 2 approach

[0076] In this embodiment, a mode in which a conductive filler that imparts conductivity is used as an insoluble function-imparting filler will be described. A conductive silicon composition containing a conductive filler in liquid silicon can be used as a conductive paste or the like.

[0077] Components, ratios, and the like other than the non-solubilizing function-imparting filler are the same as those of the silicon composition described in the first embodiment.

[0078] As fillers that can be used as non-solubilizing function-imparting fillers, any one or more selected from metals, metal oxides, and carbon compounds can be cited. These fillers may be the same fillers as those used in the above-mentioned embodiment as long as they have conductivity.

[0079] It is also preferable to contain the conductive filler in the range of 300 to 2500 parts by weight with respect to 100 parts by weight of liquid silicon. This is because the effect of the filler is not remarkable whe...

no. 3 approach

[0081] In the present embodiment, an embodiment in which a strength-imparting filler is used as an insoluble function-imparting filler will be described. A silicon composition containing a strength-imparting filler in liquid silicon can be used as a sealing material or the like for filling voids in buildings or the like.

[0082]Examples of the insoluble function-imparting filler used for the purpose of imparting strength include various fillers such as calcium carbonate and silica in addition to the thermally conductive fillers and electrically conductive fillers described in the above embodiments. Components, ratios, and the like other than the non-solubilizing function-imparting filler are the same as those of the silicon composition described in the first embodiment.

[0083] Variation

[0084] As the insoluble function-imparting filler contained in each of the above-mentioned embodiments, the filler (A) having an average particle diameter of 50 μm or less and the thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com