Grinding roller and methods for pulling off a strap and shrinking a strap onto the shaft of the grinding roller

A technology of rollers and tires, applied in the direction of grain processing, etc., can solve complex problems and achieve the effect of effective cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

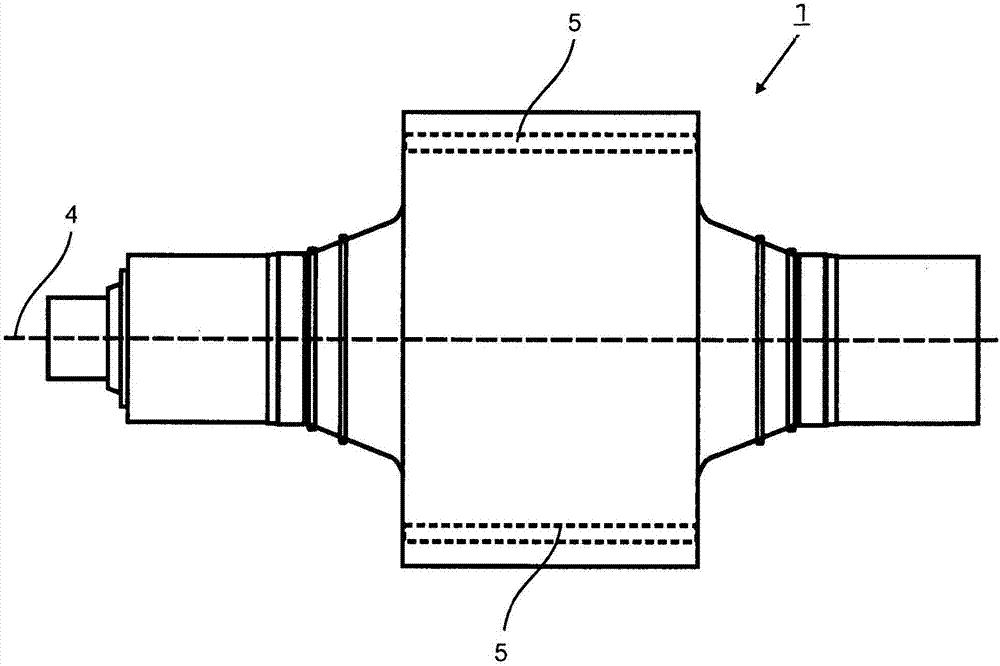

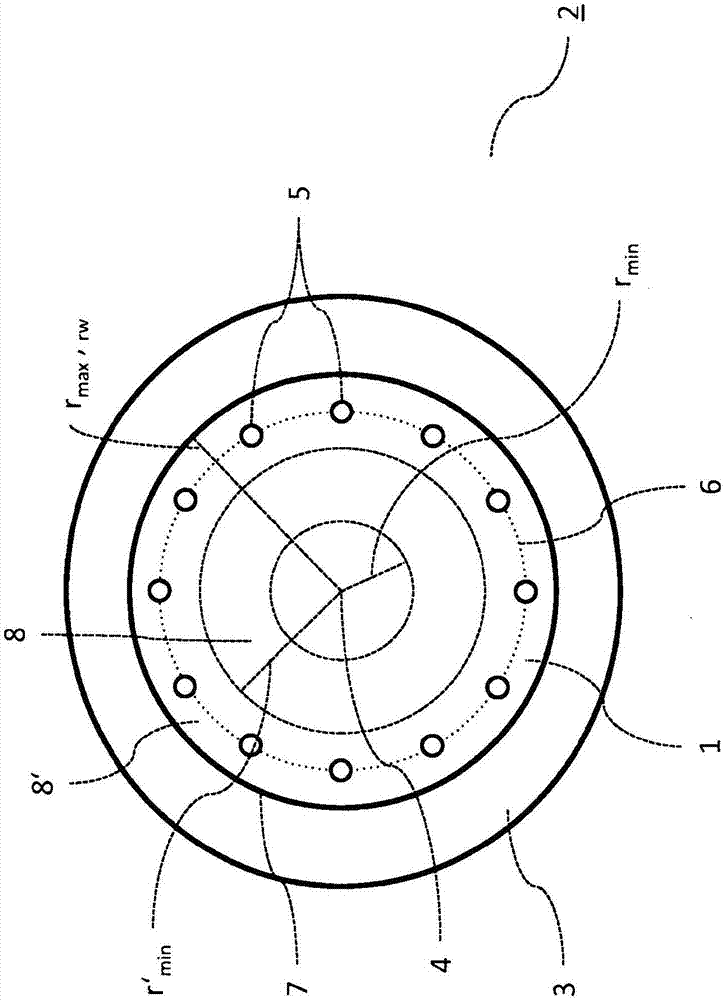

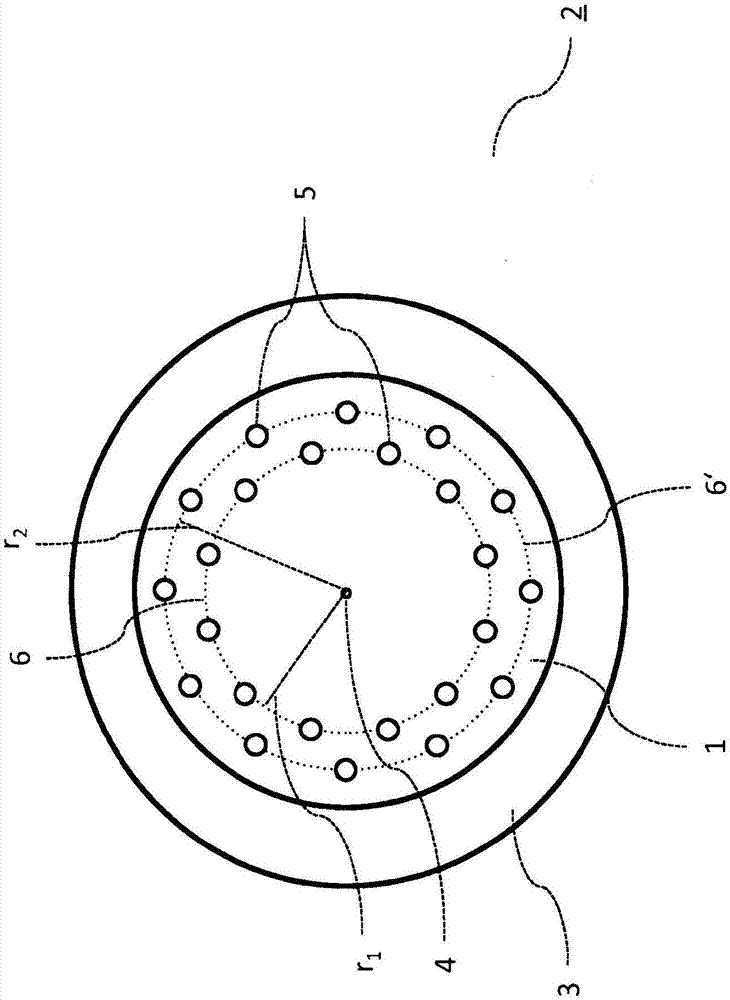

[0023] exist figure 1 The shaft 1 of a roll 2 according to the invention, which is typically used in high-pressure rolling machines (rollers), is shown in side view. The roller 2 comprises a shaft 1 and a wear-resistant web 3 , not shown here together, which is connected to the shaft 1 in a shrink-fit connection. The shaft 1 is mounted rotatably and rotationally symmetrically with respect to the axis of rotation 4 and tapers towards the ends for better support, lighter weight and easier mounting of the tire 3 from the center of the shaft 1 with the largest diameter Remove from the section and put the tire on the section. Furthermore, two cooling holes 5 arranged according to the invention in the outer region of the shaft 1 are shown schematically. The two cooling holes pass through the shaft 1 in the longitudinal direction and have open ends on both sides, so that when the tire 3 is shrunk onto the shaft 1 in the method according to the invention and is non-positively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com