Full-automatic unpacking, packing and sealing all-in-one machine

A fully automatic, all-in-one technology, used in packaging sealing/fastening, packaging, packaging bottles, etc., can solve the problems of low labor efficiency, high labor intensity, and the bottle clamping robot is not soft enough, so as to improve labor efficiency and ensure packaging. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

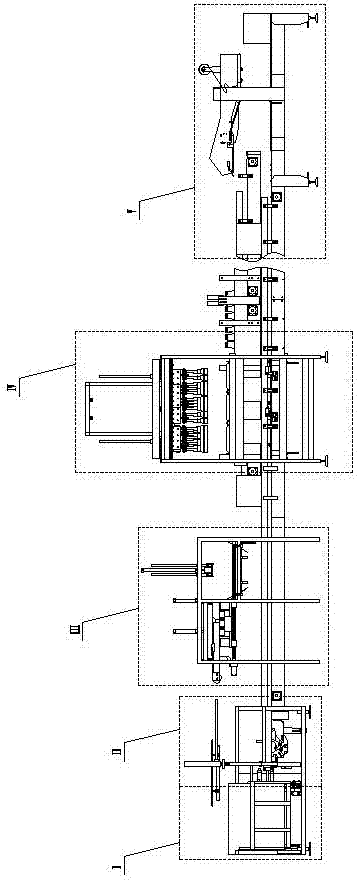

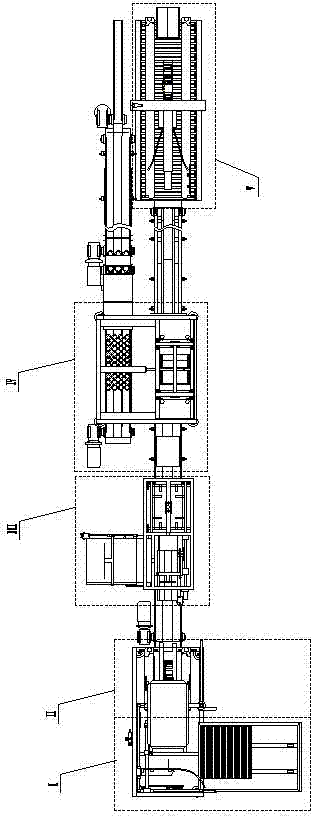

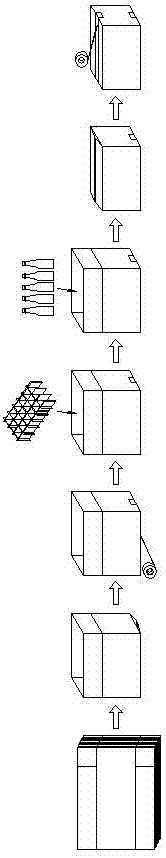

[0035] Such as figure 1 and figure 2 The full-automatic box opening, packing and sealing all-in-one machine shown takes the moving direction of the box body as the longitudinal direction, and the box body moves forward. III. Packing device IV and box capping device V, figure 1 and figure 2The dotted frame in the box only roughly distinguishes the above-mentioned devices, but does not specifically limit each device. The machine also includes a box conveying device that is self-penetrating and longitudinally arranged; the box conveying device includes a The unpacking conveying device, the case conveying device located between the unpacking frame and the sealing frame, and the sealing conveying device connected to the sealing frame, the unpacking conveying device includes a plurality of unpacking conveying devices arranged in two rows Roller, there is a conveyor belt between the unpacking conveyor rollers in the same row. When the unpacking device unpacks the box and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com