Electric heating tube moisture-proof magnesia powder and proportioning method

A technology of magnesium oxide powder and electric heating tubes, which is applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of fried tubes, reduce the service life of electric heating tubes, and increase pressure, so as to improve moisture resistance and insulation performance and service life, the effect of preventing tube explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

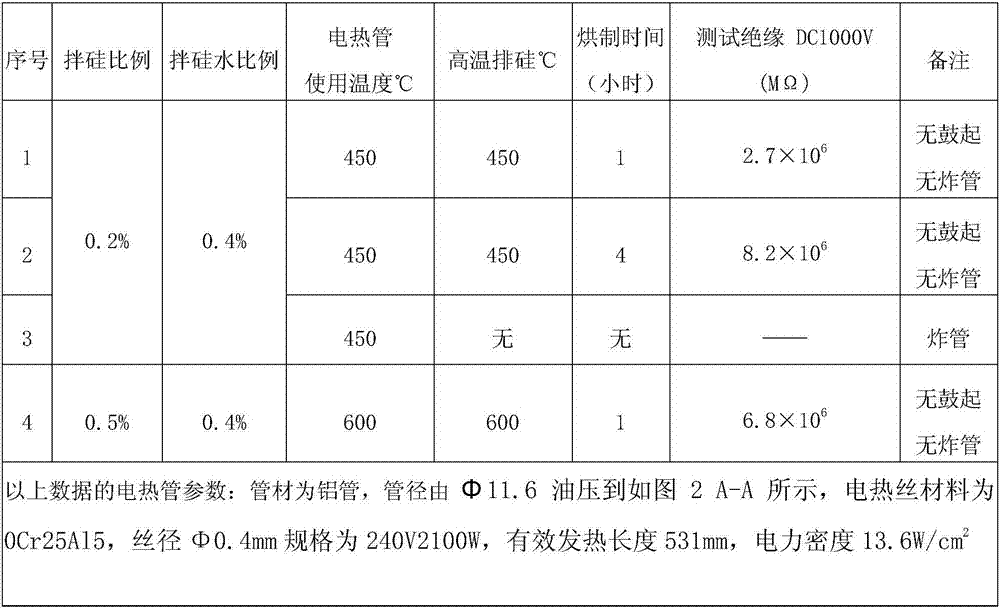

Embodiment 1

[0021] Embodiment 1: The best embodiment: This electric heating tube moisture-proof magnesium oxide powder is made by fully mixing silicon powder, silicon water and magnesium oxide powder. The weight ratio of silicon powder and silicon water to the mixture is 0.2% and 0.4%.

[0022] The proportioning method of this electric heating tube moisture-proof magnesium oxide powder of the present invention, the method comprises the steps:

[0023] (1) Fully mix the silicon powder filtered through a 60-90 mesh sieve with silicon water and magnesium oxide powder, and the silicon powder and silicon water account for 0.2% and 0.4% by weight of the mixture. ;

[0024] (2), filling the mixture after mixing evenly into the metal outer tube of the electric heating tube to make the electric heating tube;

[0025] (3) The completed electric heating tube is subjected to the silicon discharge process, and the gas is exhausted before it is completely sealed. The silicon discharge process requires...

Embodiment 2

[0027] Example 2: The difference from Example 1 is that this electric heating tube moisture-proof magnesium oxide powder is made by fully mixing silicon powder, silicon water and magnesium oxide powder, and the proportion of silicon powder and silicon water in the mixture is 0.5% by weight , 0.4%.

Embodiment 3

[0028] Embodiment 3: This electric heating tube moisture-proof magnesium oxide powder is made by fully mixing silicon powder, silicon water and magnesium oxide powder. The weight ratio of silicon powder and silicon water to the mixture is 0.3% and 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com