Copper granule production device

A recycling device, copper core technology, applied in cable installation device, cable installation, recycling technology and other directions, can solve problems such as high cost, copper core quality decline, scratches, etc., to achieve good consistency, high efficiency, particle size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

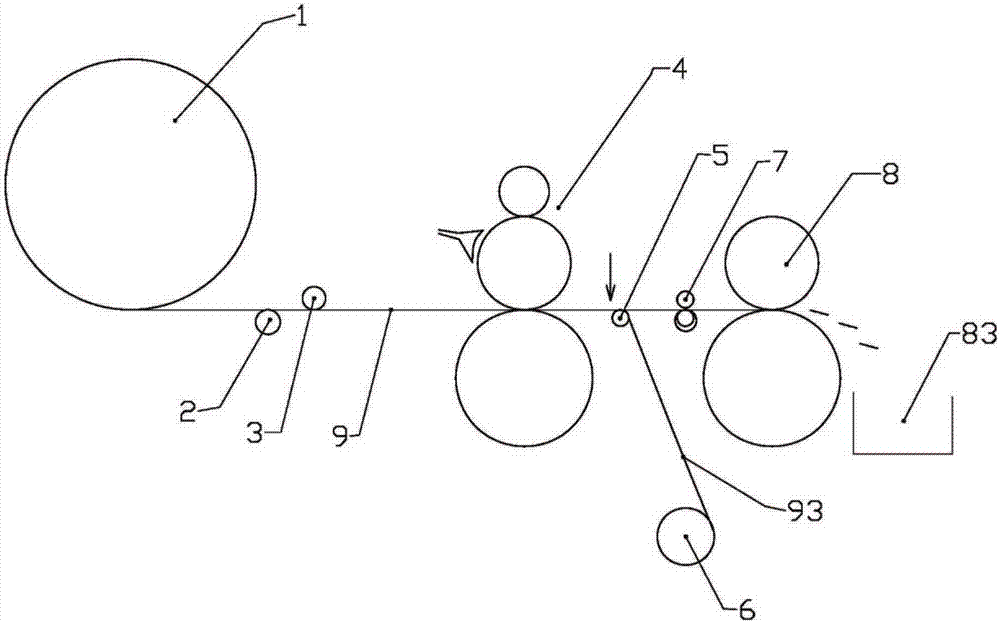

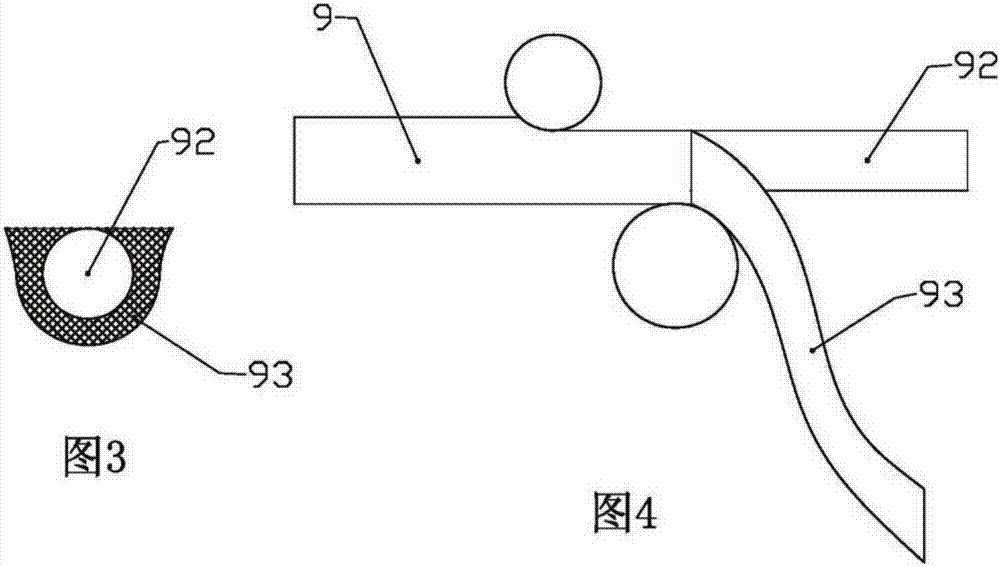

[0039] Such as Figure 1 to Figure 12 As shown, for existing defects, the subject of protection of the present invention is as follows:

[0040] What is developed is a waste cable recycling system. The single-core cable is recycled and reused. The copper rice grains produced are of good quality, which can be further passivated and rounded to form high value-added products such as copper balls, which can meet Requirements.

[0041] The basic principle is to use a non-destructive separation process to separate the copper core and sheath of the cable, then recycle the sheath, and cut the copper core to form copper particles that meet the requirements.

[0042] Based on the above description, the embodiments provided by the present invention are as follows:

[0043] The unwinding machine 1 is used to place the cable reel and realize the unwinding of the cable. The unwinding machine 1 includes a bracket 11 and an unwinding shaft 12 arranged on the bracket. For the pick-up and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com