High-density, high-flow vertical ring lift parking unit and automatic parking system

A vertical ring, high-density technology, applied in the field of automatic parking lots or parking garages, can solve the problems of low space ratio of parking spaces, high cost of use, and inability to enter and exit vehicles in batches, and achieve high density and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

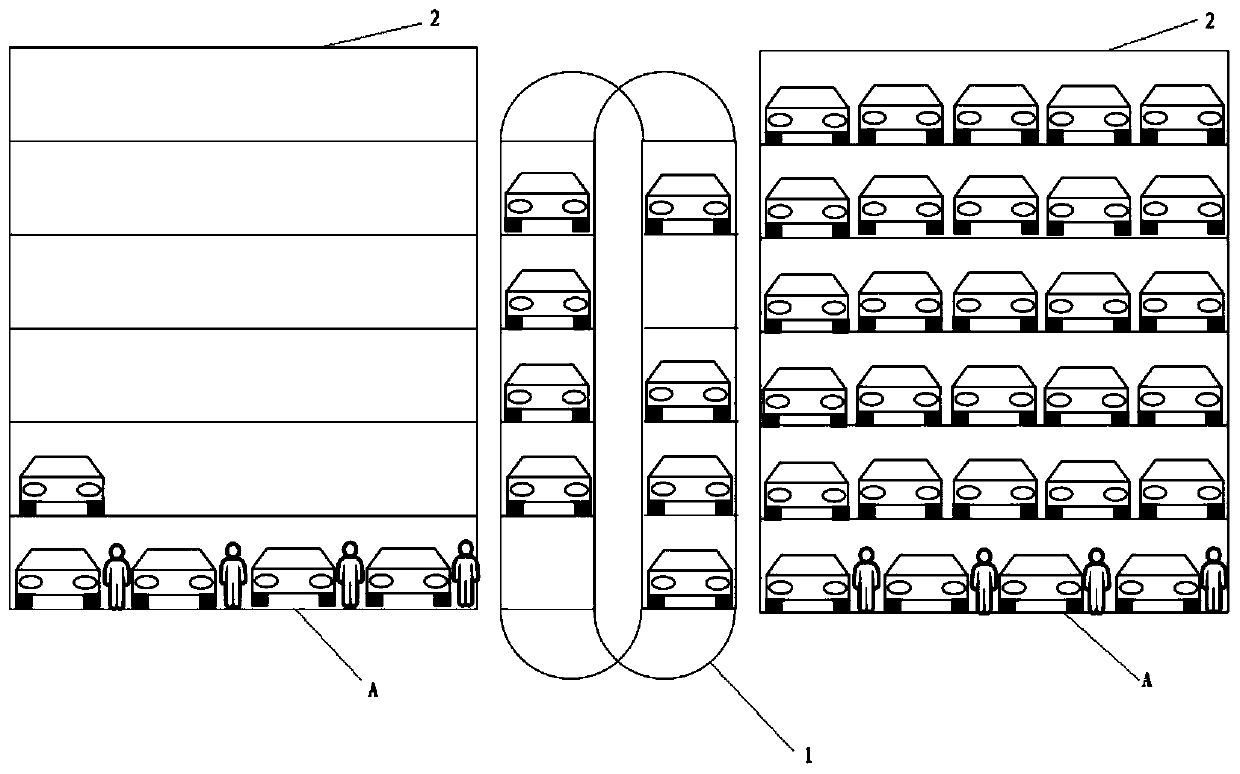

[0039] Such as figure 1 As shown, the lift can also be said to be a parking unit that can move vertically up and down, including multiple vehicle-carrying platforms. The vehicle-carrying platform is supported and guided by "double ring" rails. Optionally, a third rail is available for chain driven platforms. The lift footprint is about the size of two parking spaces. It can also be used as a "vertical" car park by itself, but even better as a quick lift in a multi-storey garage with more space, less cost, and more robustness. This is more in line with the design principle of "performing their own duties".

Embodiment 2

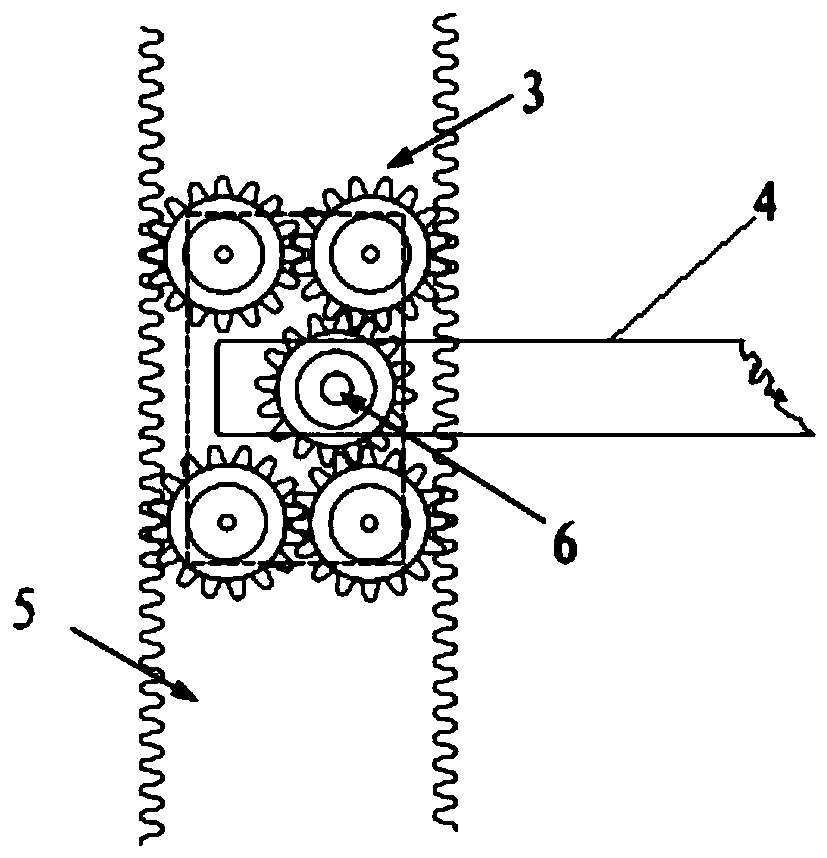

[0041] Such as figure 2 As shown, an elevator of the present invention has "double ring" grooved guide rails at both ends, which are used to support the vehicle platform and make it run along the vertical loop. The rail slots have teeth on the inside sides that engage the platform's gearing. Each platform has four gear units mounted at its four corners. Each gear unit has a plurality of gears, and the gear unit itself can rotate about a support shaft extending from the platform. A gear unit driven by a motor moves the platform along the rails. The four gears of the platform are mechanically connected to make them move at the same speed.

Embodiment 3

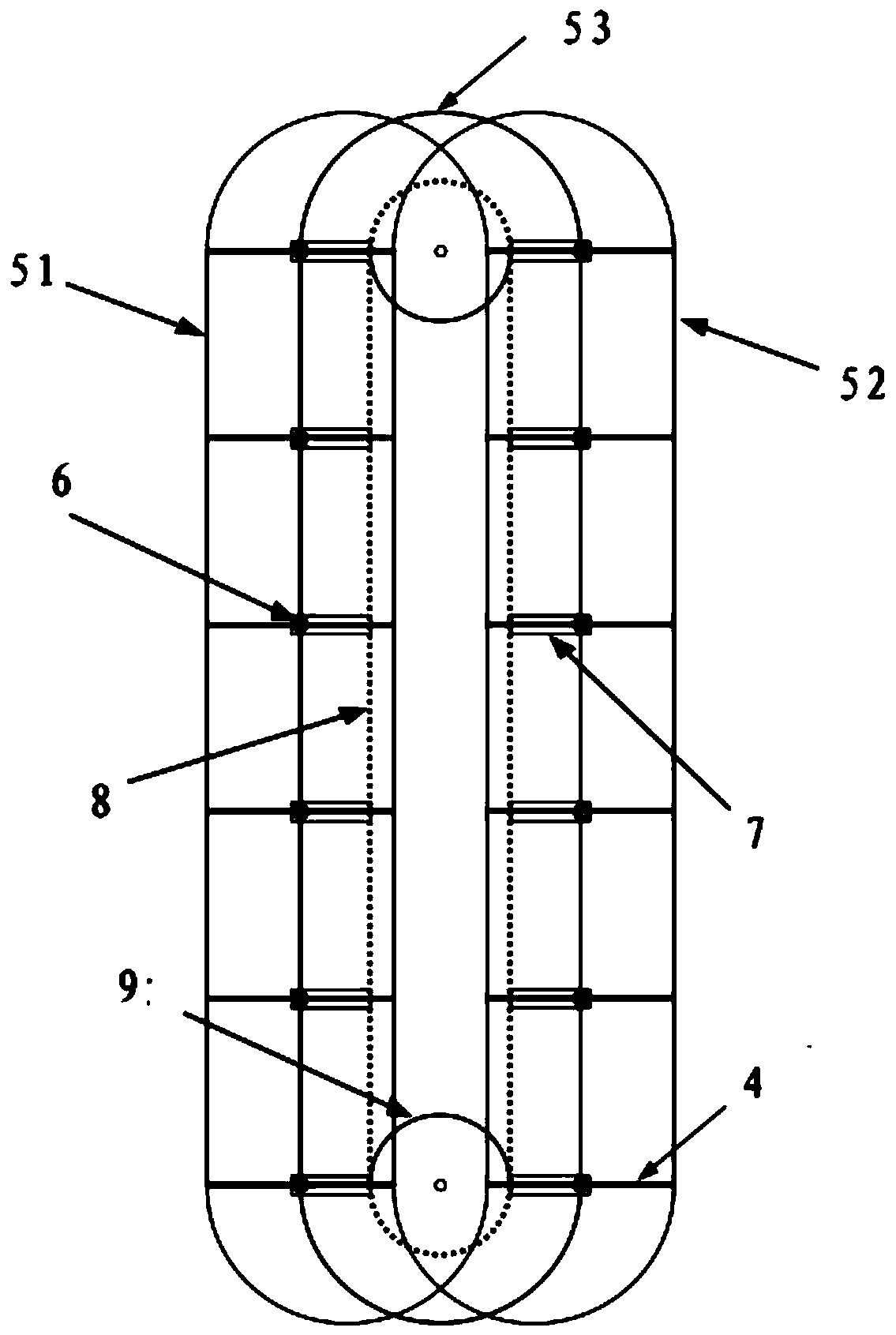

[0043] Such as image 3 Shown, the present invention can have the 3rd guide rail to be used for the operation of chain-driven vehicle-carrying platform. There is a support shaft in the middle between the gears at the two ends of the vehicle-carrying platform. The supporting shaft is connected with the driving chain through a connecting rod. The function of the connecting rod is to ensure the distance between the platforms, especially when the platform moves in a circle at the upper and lower ends of the elevator. The chain is driven by a motor from one of the upper and lower sprockets connected to it. The gearing of such a platform does not require a motor drive.

[0044] With the chain-driven third guide rail, the distance between the vehicle-carrying platforms is mechanically fixed, reliable and unchangeable. Without this third rail, the platform spacing is controlled by a software program and is variable. This variability is sometimes useful, such as enabling the vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com