Process and Assembly Method of Cathode Steel Rod with Slit at Golden Section Point

A golden section point and cathode steel rod technology, which is applied in the construction and production of electrolytic cells, can solve the problems of insignificant increase in current efficiency, limited horizontal current suppression, and sudden changes in horizontal current, so as to reduce unreasonable calorific value and improve The effect of running stability and reducing reactive power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

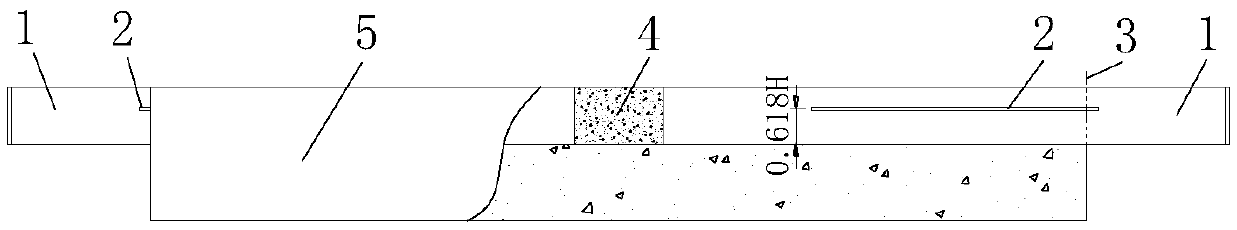

[0022] A method for processing and assembling a cathode steel rod with slits at the golden section, comprising the following steps:

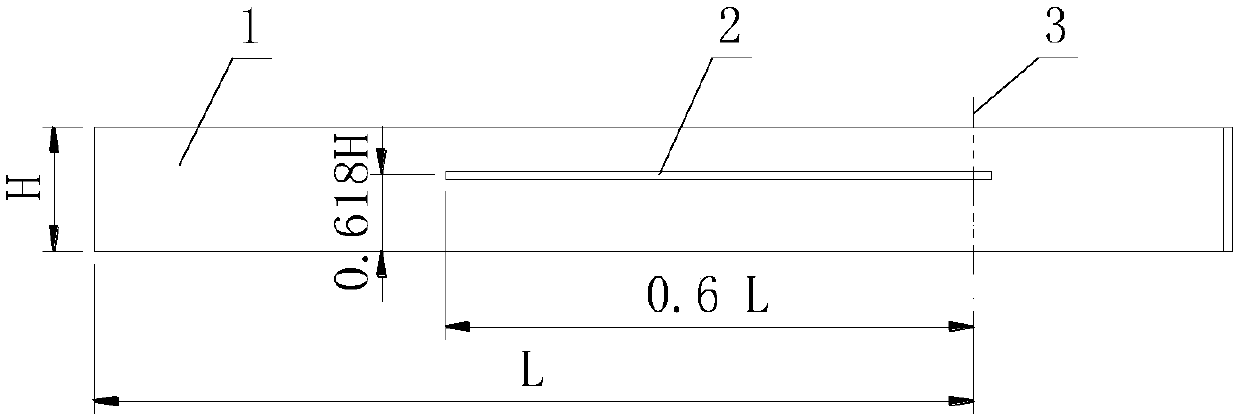

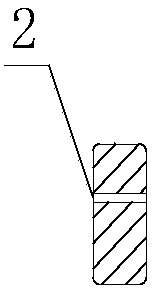

[0023] 1. Processing of cathode steel rod: such as figure 1 , 2 Shown:

[0024] Along the length direction of the cathode steel rod (1), draw the assembly cathode carbon block end position line (3), and draw the centerline of the through-slit (2) to be processed by the golden section point i.e. the 0.618H position along the height direction, The length of the through-slit (2) is 0.6 times (ie 0.6L) the length of the joint between the steel rod (1) and the carbon block when assembled. In order to ensure the cut-off effect of the through-slit (2) on the horizontal current, its length is extended by 30mm. Finally, mill the through seam (2) by the drawn long and height positioning line.

[0025] The function of the through seam (2) is to cut off the horizontal current during production, and its position must be accurate, with a position deviation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com