Novel browning treatment fluid for printed circuit board

A treatment liquid and browning technology, which is applied in the secondary treatment of printed circuits, printed circuits, printed circuit manufacturing, etc., can solve the problems of short processing time and poor tear strength, and achieve improved peel strength and good thermal shock resistance , Improve the effect of corrosion inhibition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

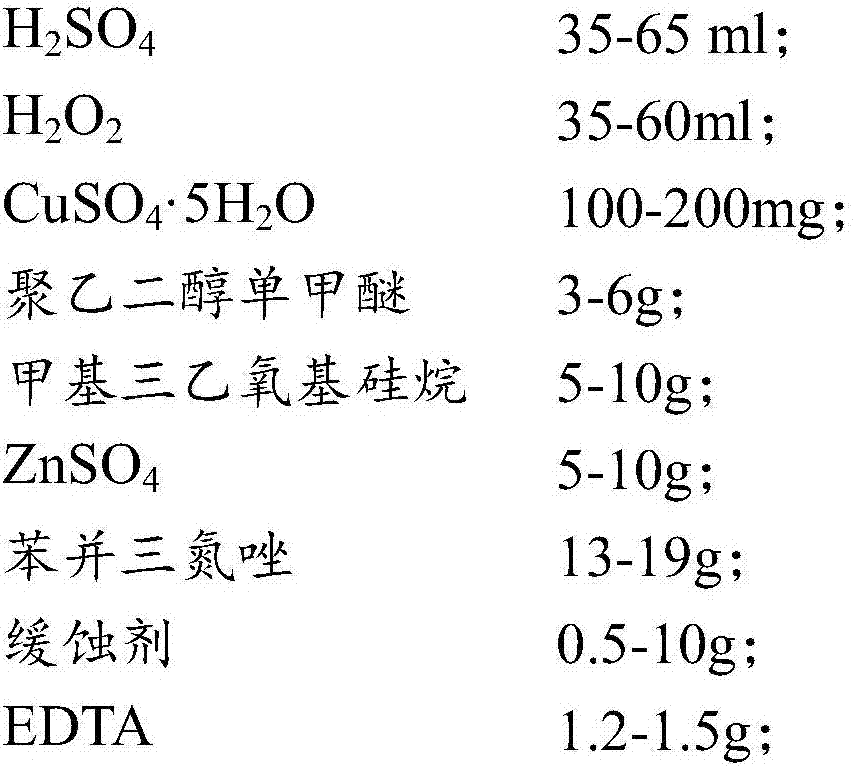

[0040] A novel browning treatment liquid, its composition is as follows:

[0041]

[0042]

[0043] According to the aforementioned browning treatment process, the browning solution is sprayed horizontally in the PVC browning tank to brown the pre-soaked PCB surface, the browning time is 50s, and the temperature is 35°C.

[0044] After testing, a uniform brown-black copper surface with a microetching depth of 1.44um can be obtained after browning. The surface roughness after browning was characterized by a TR200 roughness meter. The results are shown in Table 1. Using a SEM microscope to observe the copper surface, it can be observed that the copper surface has a fine and uniform honeycomb structure. These honeycomb structures endow the treated copper surface with better bonding force, which is conducive to increasing the copper / resin bond during the lamination process. The specific surface area of the indirect contact can promote the cross-linking reaction between the...

Embodiment 2

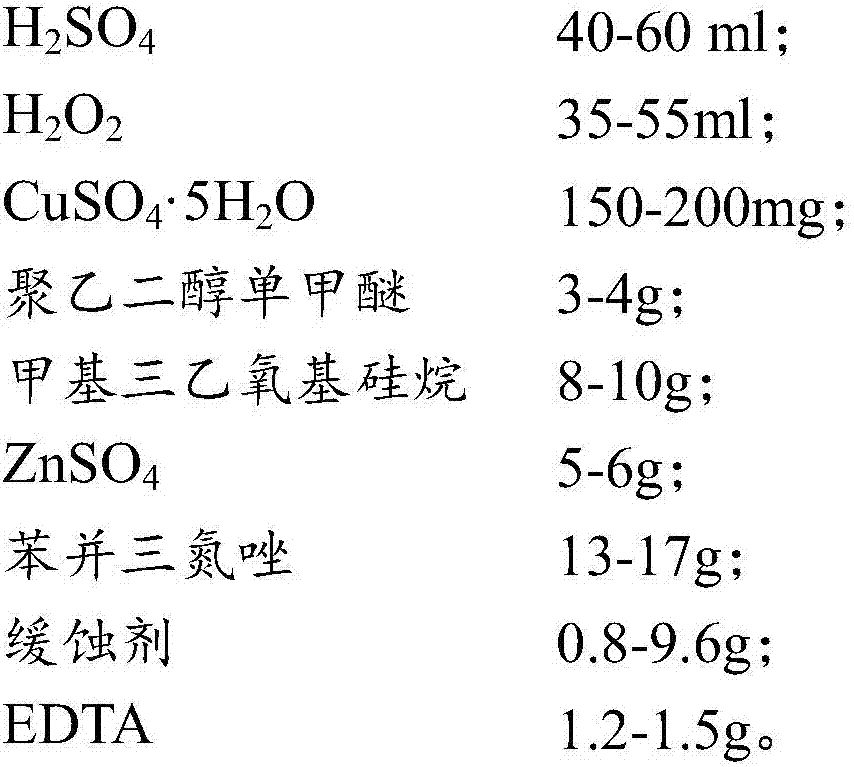

[0046] A novel browning treatment liquid, its composition is as follows:

[0047]

[0048] According to the aforementioned browning treatment process, the browning solution is sprayed horizontally in the PVC browning tank to brown the pre-soaked PCB surface, the browning time is 40s, and the temperature is 35°C.

[0049] The results show that after browning, a uniform brown-black copper surface with a microetching depth of 1.21um can be obtained. The surface roughness after browning is characterized by TR200 roughness meter. The surface has a fine and evenly distributed honeycomb structure. These honeycomb structures endow the treated copper surface with better bonding force, which is beneficial to the pressing of multi-layer boards and prevents the occurrence of burst boards, indicating that the browning liquid has good bonding strength; after lamination, the peel strength between the copper surface and the prepreg is 5.9Ib / in; under the condition of 288 ℃, it can satisfy ...

Embodiment 3

[0051] A novel browning treatment liquid, its composition is as follows:

[0052]

[0053] According to the aforementioned browning treatment process, the browning solution is sprayed horizontally in the PVC browning tank to brown the pre-soaked PCB surface, the browning time is 50s, and the temperature is 35°C.

[0054] The results show that after browning, a uniform brown-black copper surface with a microetch depth of 1.12um can be obtained. The surface roughness after browning was characterized by a TR200 roughness meter. The results are shown in Table 1. Using SEM microscope to observe the copper surface, it can be seen that the copper surface has a fine and evenly distributed honeycomb structure. These honeycomb structures endow the treated copper surface with better bonding force, which is beneficial to the lamination of multi-layer boards and prevents the occurrence of burst boards. , indicating that the browning solution has a good bonding force; the peel strength b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com