Automotive glass pu extrusion curing cycle line

A technology of automotive glass and vitrification, which is applied in the direction of mechanical conveyors, transportation and packaging, conveyors, etc., can solve the problems of low degree of automation, manual control of curing time, waste of manpower, etc., to improve curing quality and ensure extrusion Curing time, the effect of reasonable structural layout design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

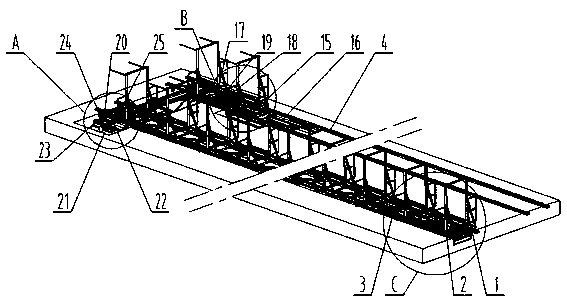

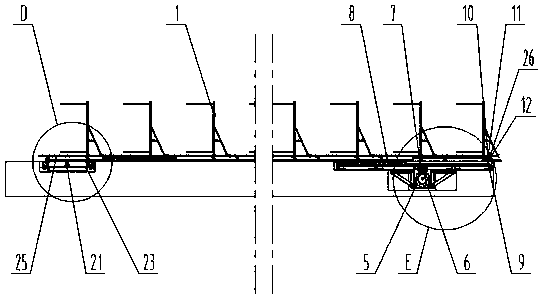

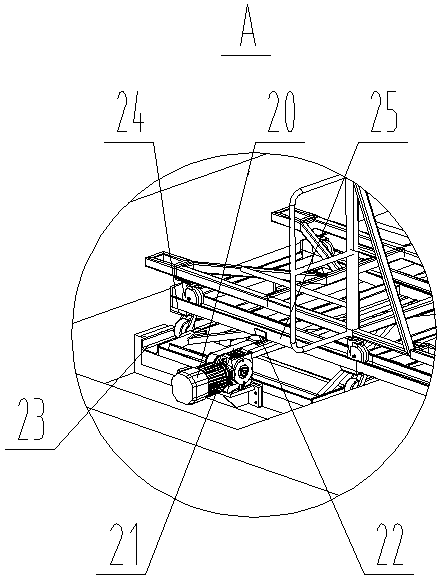

[0016] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, the present invention includes an automobile vitrification chamber body, and a vitrification circulation line is also provided in the automobile vitrification chamber body, and the vitrification circulation line includes a group of vitrification racks 1 and the step-by-step moving mechanism of the curing frame, the bottom of the vitrification frame 1 is provided with a road wheel device 2, and the step-moving mechanism of the curing frame includes a room-entry section curing frame moving track 3, a first stepping power device, for The curing frame is transferred from the room-entry section to the curing frame steering device of the room-out section, the room-out section curing frame moving track 4 and the second stepping power device, the room-entry section curing frame moving track 3 and the room-out section curing frame moving track 4 are respectively laid on the ground of the automobile vitrification chamber body, and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com