Anti-clogging reaction vessel

A reaction kettle and anti-clogging technology, which is applied in the direction of chemical/physical/physical chemical fixed reactor, filtration separation, fixed filter element filter, etc. Problems such as production and operation costs can be achieved by reducing extremely easy blockage, increasing sealing effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in detail below in conjunction with embodiments. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

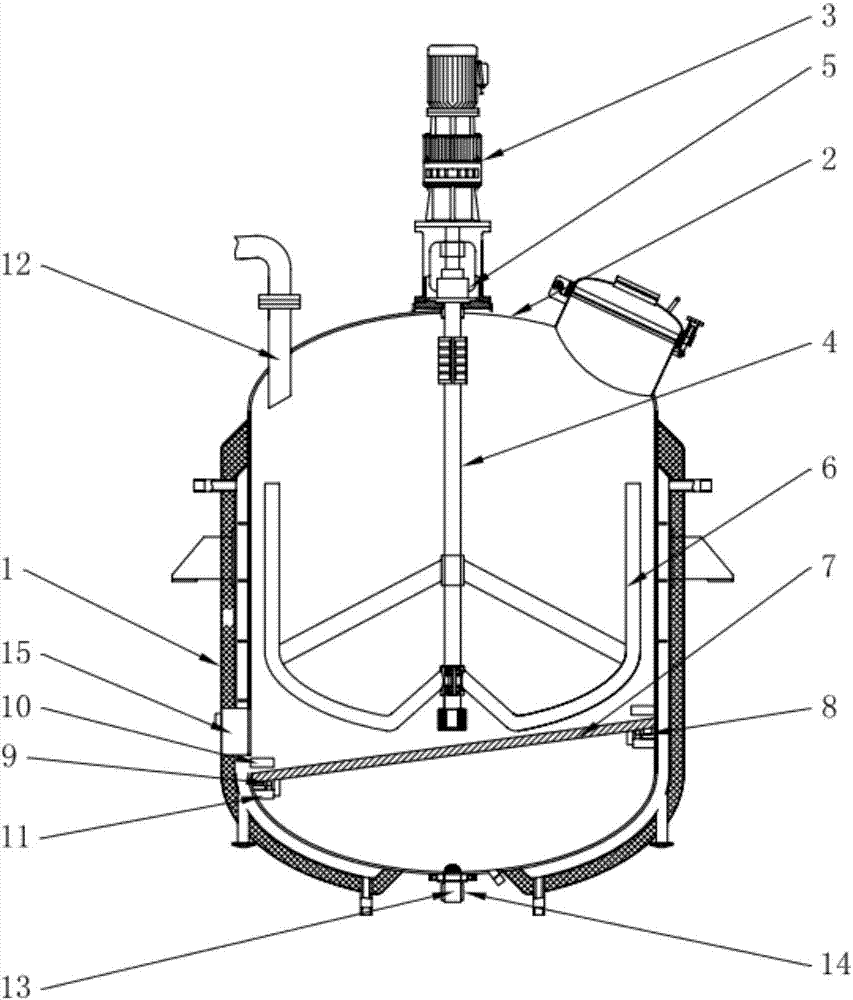

[0024] Such as figure 1 As shown, an anti-clogging reaction kettle includes a kettle body 1, a kettle cover 2 is installed on the top of the kettle body 1, and a stirring mechanism is installed on the kettle cover 2. The stirring mechanism includes a power part 3, a stirring shaft 4 and a shaft seal part 5. One end of the stirring shaft 4 is power-installed with the power part 3, and the other end of the stirring shaft 4 passes through the kettle cover 2 and extends into the interior of the kettle body 1, and the stirring shaft 4 placed inside the kettle body 1 is equipped with a stirring blade 6 , the stirring shaft 4 is equipped with a shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com