A discharge device for an extruder

A discharge device and extruder technology, which is applied in the fields of feed, oil, and food processing, can solve the problems of high-temperature burns, internal and external pressure differences of the discharge device, low working efficiency of the extruder, and large internal and external pressure differences of the discharge device. Avoid machine blockage, ensure uniformity, and simple lubricating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

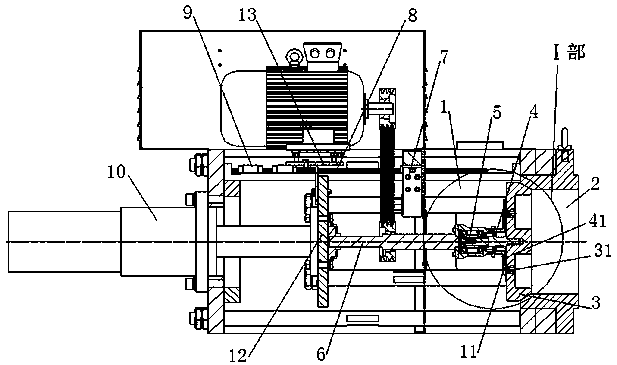

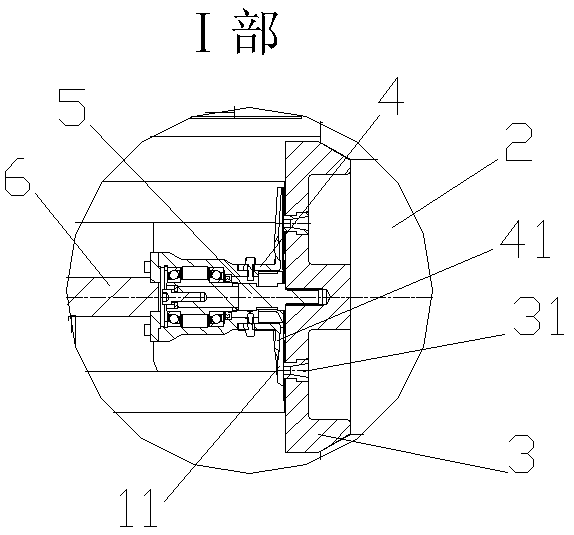

[0021] The technical solution adopted by a new type of puffing machine discharge device of the present invention is: the present invention includes a puffing chamber 1, one end of the puffing chamber 1 is connected to the discharge port 2, and the junction between the puffing chamber 1 and the discharge port 2 is set There is a door body 3 that can move axially to connect or close the puffing chamber 1 and the discharge port 2, and the end surface of the door body 3 on one side of the puffing chamber 1 is provided with a cutting device that fits the door body 3 4. The cutting device 4 and the door body 3 move axially synchronously, and the cutting device 4 makes a circular rotation relative to the door body 3 .

[0022] The joint surface of the discharge port 2 and the door body 3 adopts a matched tapered surface to realize sealing fit.

[0023] The door body 3 is provided with a plurality of die holes 31 , and the positions of the die holes 31 are in the area covered by the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com