Miniature mechanized small-granule crop sower applicable to drought hilly area

A seeder and drought technology, applied in the field of micro-mechanized small-grain crop seeders, can solve problems affecting production efficiency, difficulties in sesame seedling emergence, and affecting farmers' enthusiasm for planting, and achieve good seeding effects and excellent cross-country performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

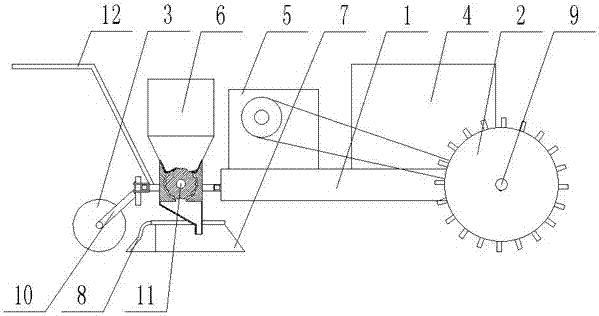

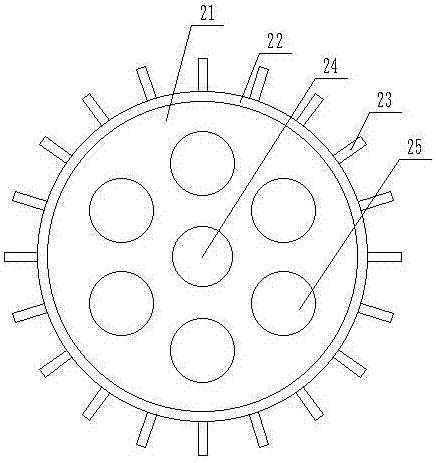

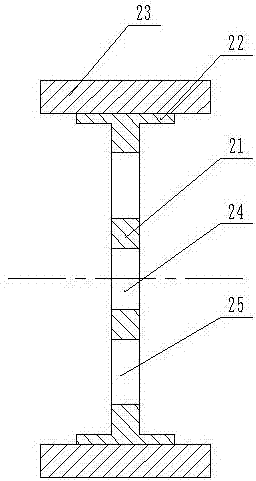

[0024] Such as Figure 1 to Figure 4 As shown, the present invention is suitable for the miniature mechanized small-grain crop seeder in arid hilly areas, including frame 1, ground wheel 2, pressing wheel 3, engine 4, transmission 5, feeding mechanism 6, ditching mechanism 7 and soil covering mechanism 8, The front end of the frame 1 is provided with two ground wheels 2 through the first transmission shaft 9, the rear end of the frame 1 is provided with two pressing wheels 3 through the roller frame 10, and the engine 4 and the transmission 5 are arranged in sequence On the frame 1, and the engine 4 transmits power to the transmission 5 through the belt, and the two unloading mechanisms 6 are respectively located on both sides of the frame 1 between the transmission 5 and the ground wheel 2, and the transmission 5 passes through the sprocket The structure transmits the power to the first transmission shaft 9 of the ground wheel 2 and the second transmission shaft 11 of the unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com