Lossless method for measuring content of bagged complex solution components

A complex and solution technology, applied in the direction of measuring devices, color/spectral characteristic measurement, and analysis of materials, to eliminate the impact of changes and packaging bags, solve non-destructive testing problems, and measure highly targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

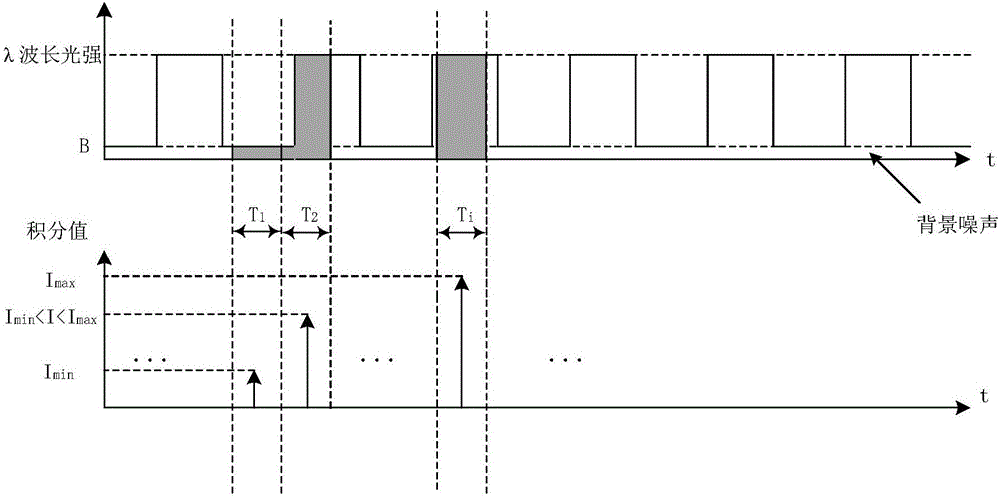

[0078] The embodiment of the present invention provides a method for non-destructively measuring the content of complex solution in bags, the devices used are such as image 3 As shown, it includes: a light source 3 , a packaging bag 5 , a displacement platform 6 , a spectrum receiving device 7 and a modulation device 9 .

[0079] Wherein, ensure that the light output port of the light source 3 and the incident slit of the spectrum receiving device 7 are close to the packaging bag 5, and the modulating device 9 modulates the light source 3 so that it sends out a square-wave light signal, and the light source 3 is at the position a under the two optical paths that are : position a (corresponding to the first optical path 1) and position a' (corresponding to the second optical path 2) transmit and excite the complex solution sample in the packaging bag 5, and the transmission spectrum and the fluorescence spectrum are collected by the spectrum receiving device 7; then Control th...

Embodiment 2

[0088] The difference between the embodiment of the present invention and embodiment 1 is only that the light source 3 and the movement mode of the spectrum receiving device 7 are different, see the following description for details:

[0089] see Figure 4 To ensure that the light outlet of the light source 3 and the incident slit of the spectrum receiving device 7 are close to the packaging bag 5, the modulation device 9 modulates the light source 3 so that it sends out a square wave light signal, and the light source 3 transmits and absorbs the complex solution sample in the packaging bag 5 Excited, the spectrum receiving device 7 collects the transmission spectrum and the fluorescence spectrum under the double optical path at position a, namely: position a and position a'. Control the spectrum receiving device 7 to move to the position b through the displacement platform 6, and collect the transmission spectrum and the fluorescence spectrum at the position b under the doubl...

Embodiment 3

[0094] During specific implementation, due to the limitation of the space structure, it may occur that the light source 3 and the spectrum receiving device 7 cannot be close to the packaging bag 5. At this time, an optical fiber can be respectively arranged at the light source 3 and the spectrum receiving device 7 as the incident optical fiber 4 and outgoing optical fiber 8.

[0095] see Figure 5 , the modulation device 9 modulates the light source 3 to make it emit a square wave light signal, the light source 3 transmits and excites the complex solution sample in the packaging bag 5 through the incident optical fiber 4, and the spectrum receiving device 7 collects the transmission spectrum and the fluorescence spectrum through the outgoing optical fiber 8, The incident optical fiber 4 and the outgoing optical fiber 8 are respectively close to the packaging bag 5, the incident optical fiber 4 is at position a, and the light source 3 passes through the incident optical fiber 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com