Split type high-precision planet carrier and manufacturing method thereof

A processing method and planet carrier technology, applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve problems such as aggravating system vibration, increasing the meshing frequency of planetary transmission units, and failure of planetary row components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

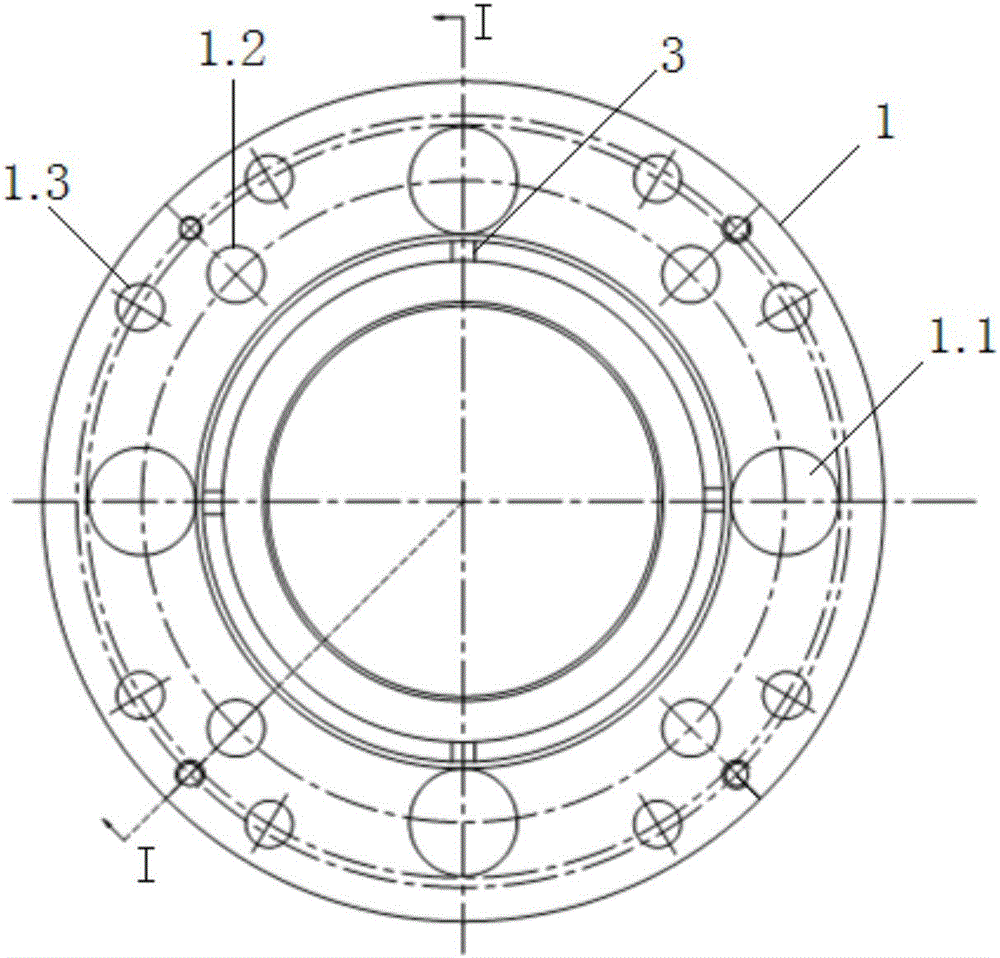

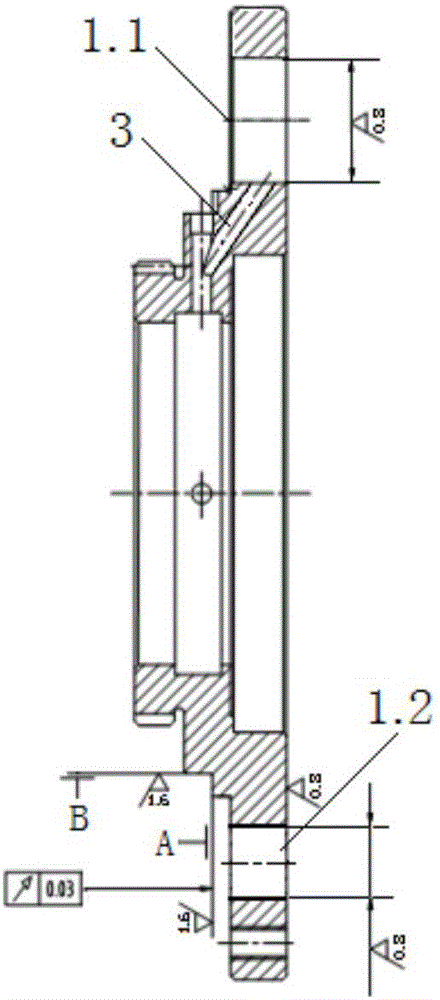

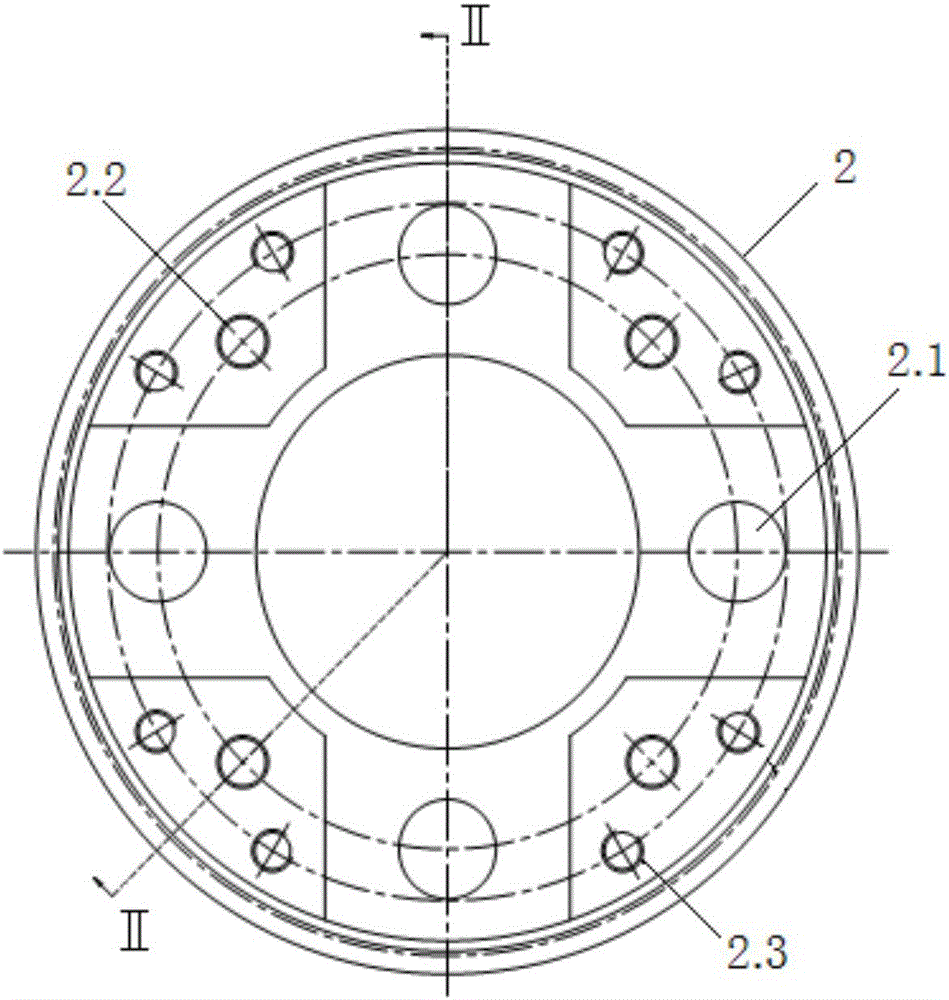

[0044] In order to maintain high precision in the positioning holes, support holes and planetary wheel shaft holes of the split planetary carrier during processing, dismantling, installation and component assembly, reduce internal excitation caused by eccentricity, misalignment and transmission errors, and reduce vibration, the present invention provides A split planetary carrier design scheme, after the main and auxiliary planetary carriers complete the processing of dimensional elements, structural elements (splines, support holes, etc.) Combining, processing, and positioning, and then completing the design of the planetary gear shaft hole size and shape and position tolerances, forming a complete overall design of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com