A kind of liquor reprocessing technology

A technology for reprocessing and liquor, applied in the field of liquor reprocessing technology, can solve the problems of not being able to market the liquor in time, high storage cost, affecting the quality of liquor, etc., and achieve the effects of enhancing affinity, good taste and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

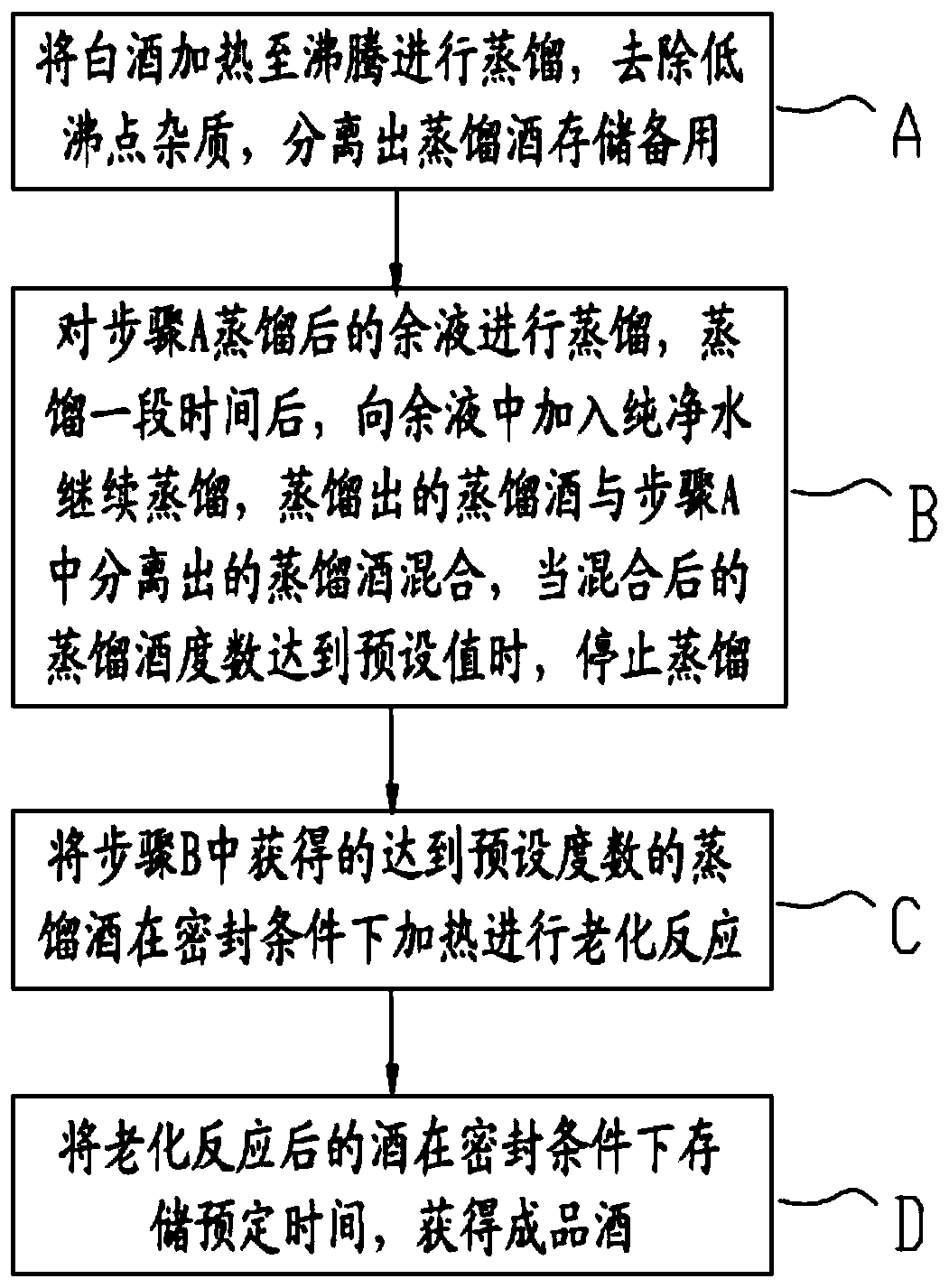

[0033] Such as figure 1 Shown, a kind of liquor reprocessing technique comprises following process:

[0034] A. Distillation: Heating the liquor to boiling to carry out distillation to remove impurities, continue to distill and separate the distilled liquor for storage for later use;

[0035] B. Reduction and purification: Distill the residual liquid after distillation in step A. After distillation for a period of time, add pure water to the residual liquid to continue distillation. The distilled wine is mixed with the distilled wine separated in step A. When the degree of distilled alcohol after mixing reaches the preset value, the distillation is stopped;

[0036] C. Aging reaction: heating the distilled liquor obtained in step B to a predetermined degree under sealed conditions to carry out aging reaction;

[0037] D. Storage: Store the wine after the aging reaction for a predetermined time under sealed conditions to obtain finished wine.

[0038] Liquor contains volatil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com