PVC film applied to window decoration

A base layer and alloy layer technology, applied in the direction of layered products, metal layered products, glass/slag layered products, etc., can solve the problems of insufficient personalization, poor sound insulation, and accelerated fire spread.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

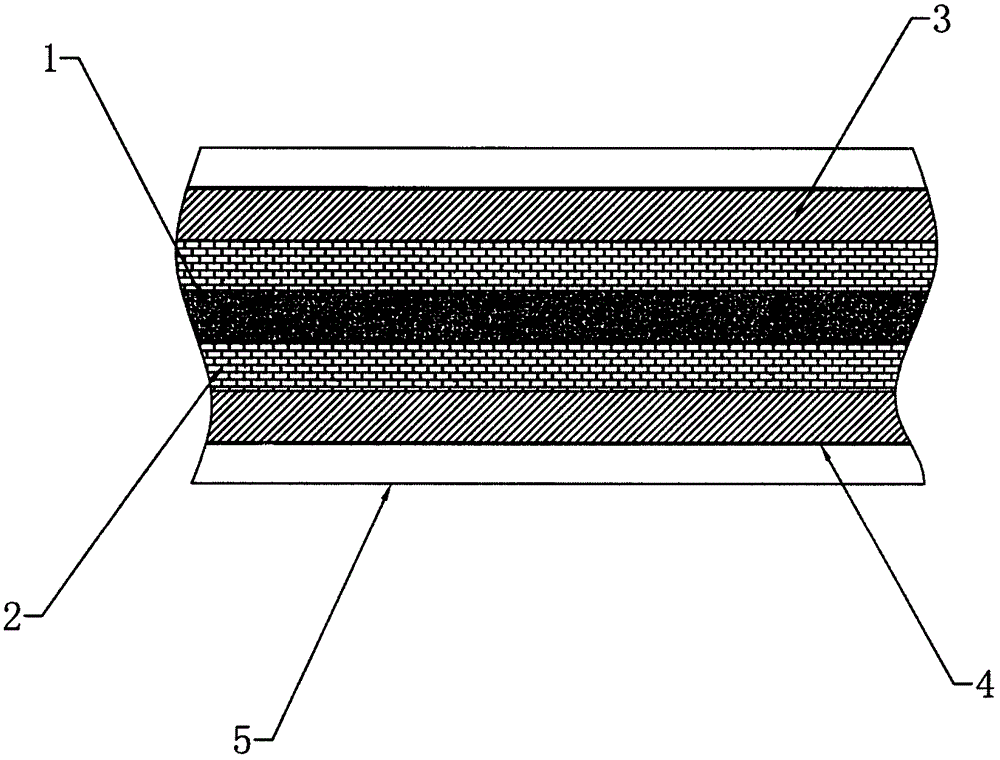

[0013] refer to figure 1 The embodiment of the PVC film of the present invention will be further described.

[0014] Such as figure 1 A PVC film shown includes a light-transmitting and soft base layer 1 and several covering layers. In this embodiment, the covering layer includes a PVC layer 2, a hafnium alloy layer 4, a PVDF layer 3 and a sound-absorbing material layer. Here, The PVC layer 2 is attached to the upper surface and the lower surface of the base layer 1, where the PVC layer 2 is attached to a surface far away from the base layer 1, and a PVDF layer 3 is attached to it, and the PVDF layer 3 here is arranged on a surface far away from the base layer 1. There is a hafnium alloy layer 4 , where a sound-absorbing layer 5 is provided on a surface of the hafnium alloy layer 4 away from the base layer 1 . And in this embodiment, the material of the base layer 1 is selected as a flexible glass layer, and the material of the sound-absorbing layer 5 is selected as sound-abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com