Multi-freedom degree laser displacement sensor system and spiral bevel gear measurement method

A technology of spiral bevel gear and laser displacement, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of inability to reflect, lose tooth surface collection point data, etc., and achieve easy operation, simple structure, and high flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

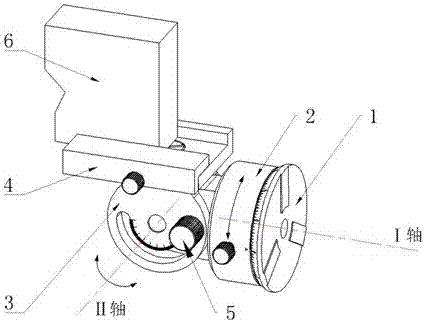

[0029] Such as figure 1 Shown is a multi-degree-of-freedom laser displacement sensor system proposed by the present invention, which includes a base 1 , a slewing frame 2 , a rotating platform 3 , a quick clamping table 4 , and a locking knob 5 . The base 1 is provided with a slewing frame 2 concentric with the central axis I axis through a rotating mechanism. The slewing frame 2 can freely rotate 360° relative to the base 1 around the central axis I axis of the base 1. The pose of the slewing frame 2 relative to the base 1 It can be fixed by the locking knob of the base 1. The rotary frame 2 is provided with a rotary platform 3 through a rotary mechanism, and the rotary platform 3 can freely rotate 180° relative to the rotary frame along the II axis. 4. The quick clamping table 4 can clamp the laser displacement sensor 6 through the pressing plate and the locking knob 5 .

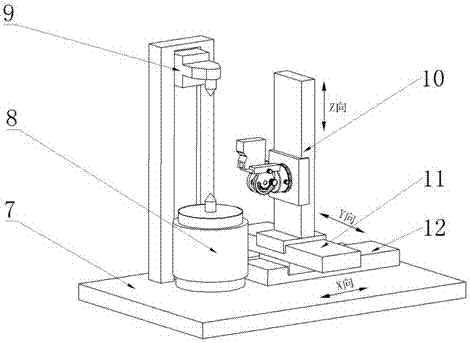

[0030] Such as figure 2Shown is the laser displacement measurement device used in the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com