Adjustable check air valve

An adjustable and non-return technology, applied in the direction of lift valve, valve device, control valve, etc., can solve the problems of poor stability, inability to realize adjustable air volume, complex structure, etc., and achieve the effect of improving the deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

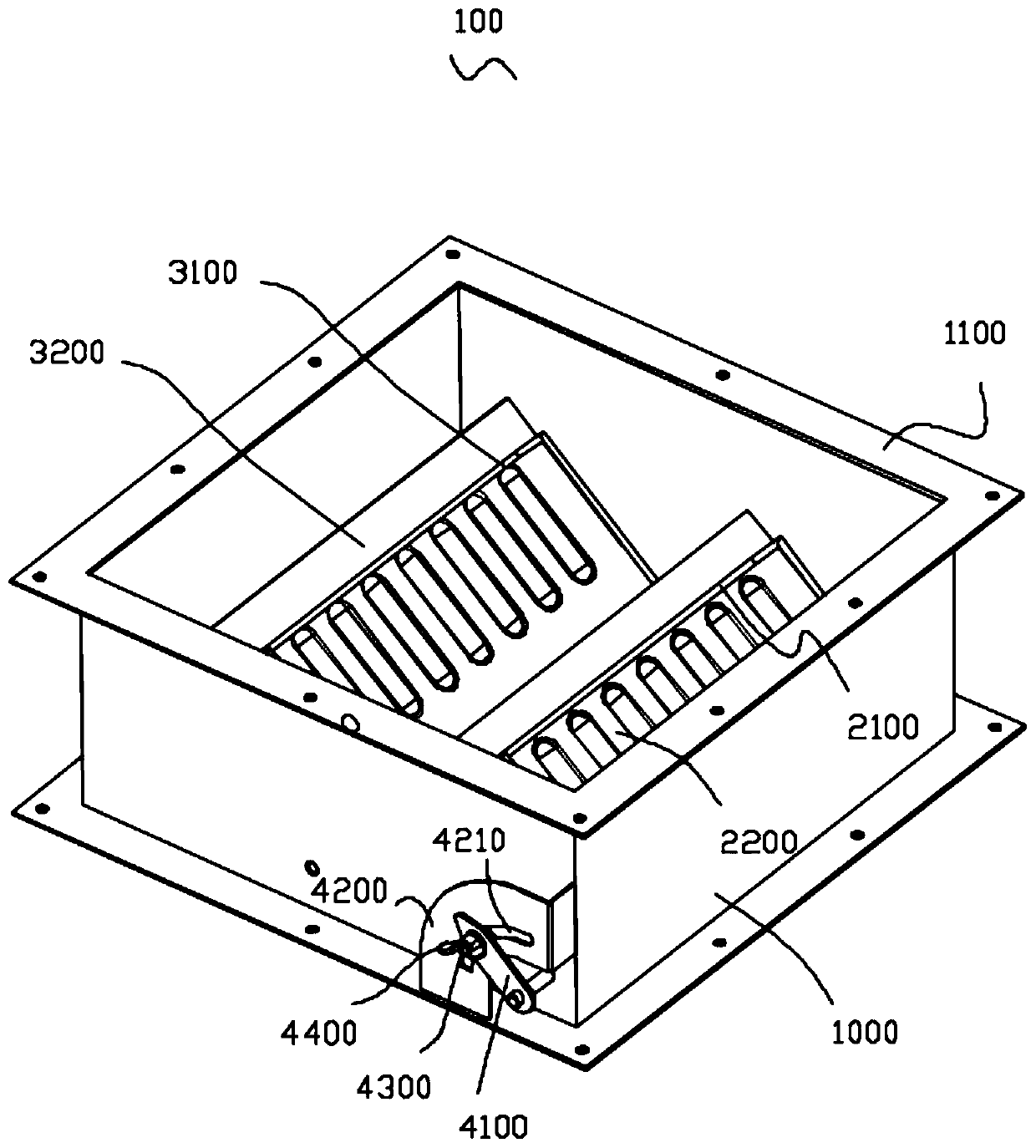

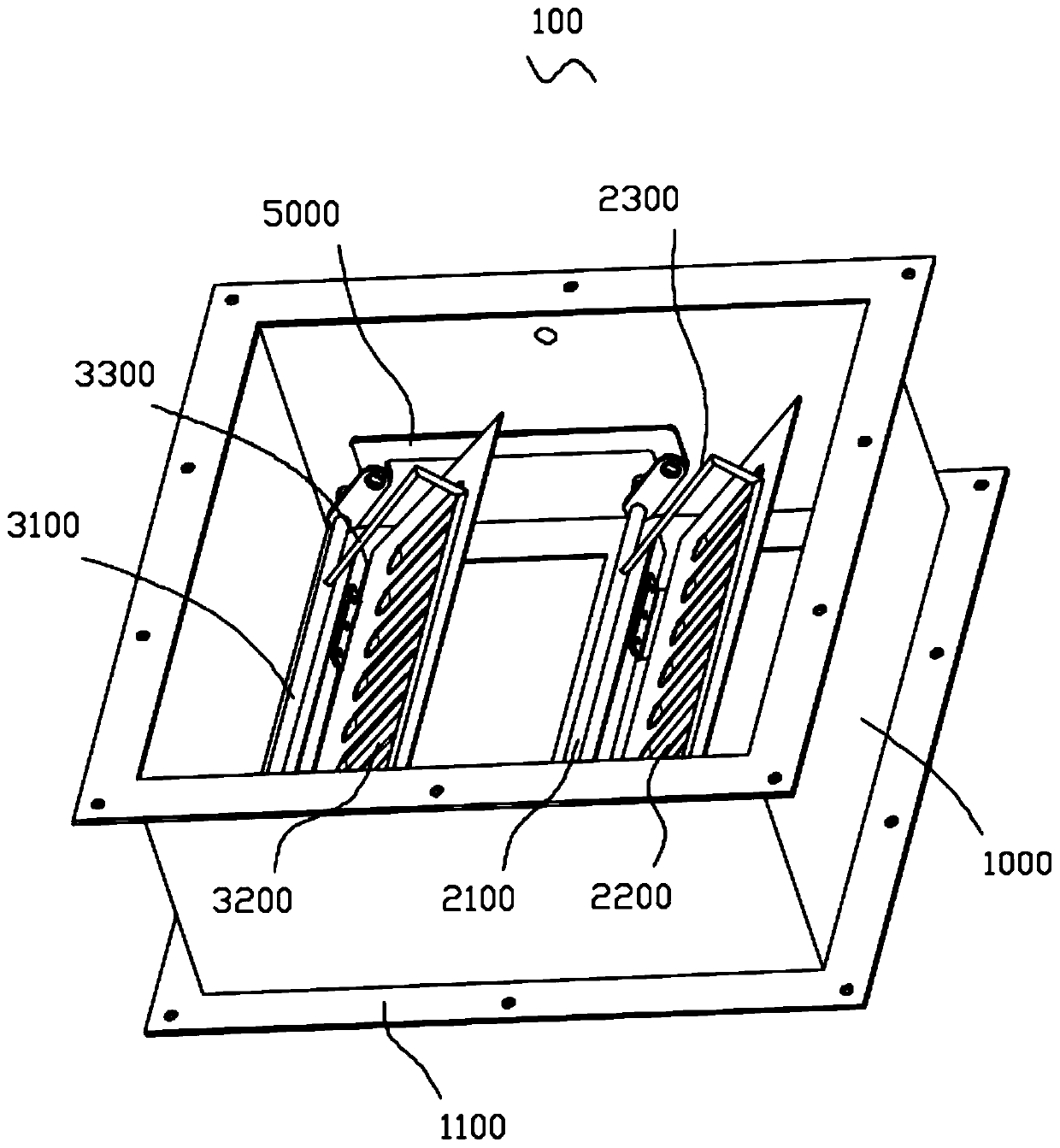

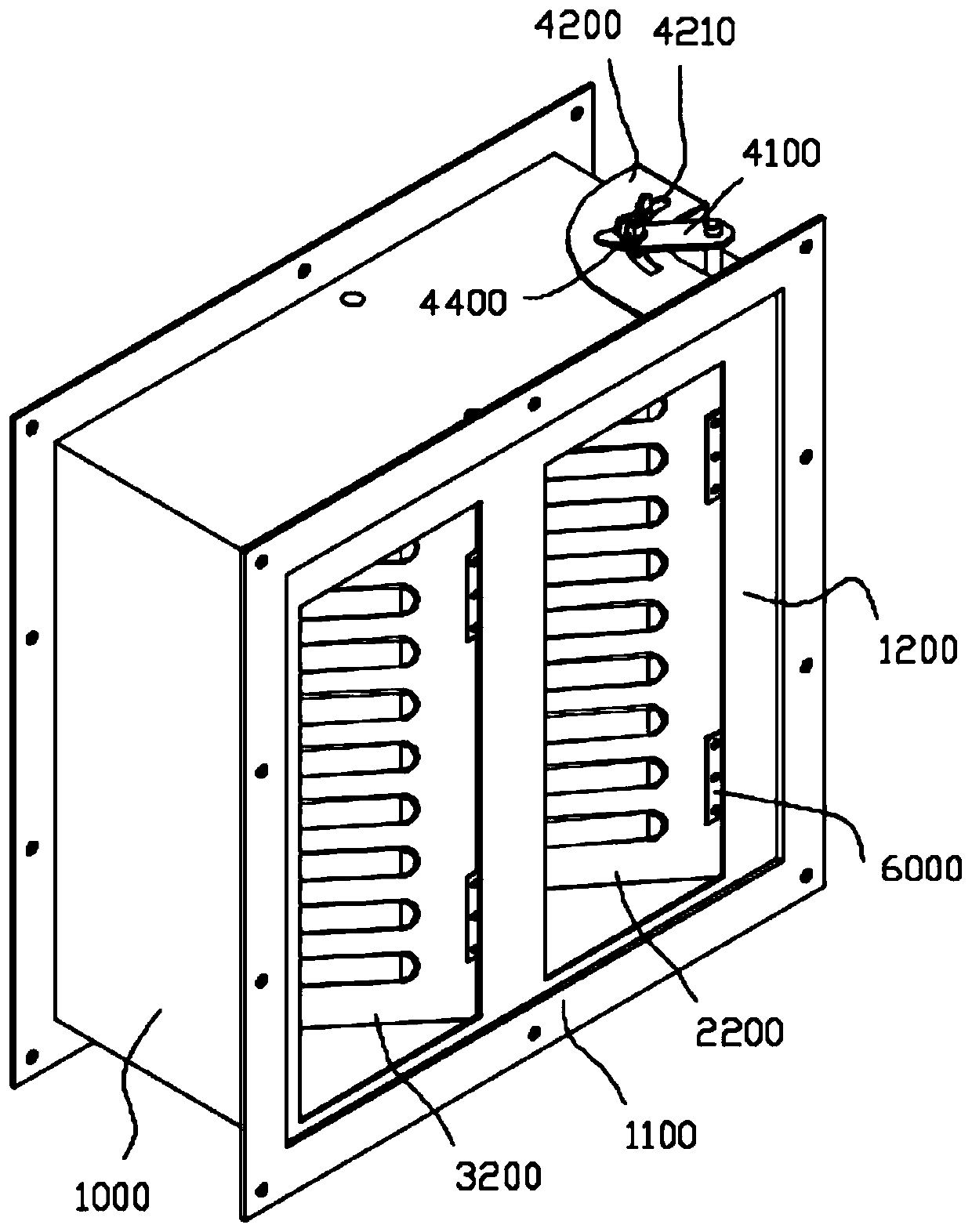

[0037] This embodiment provides an adjustable non-return air valve 100, the number of adjusting blades in the adjustable non-return air valve 100 is two, that is, the adjustable non-return air valve 100 is a double-blade adjustable non-return air valve 100 .

[0038] Specifically, please also refer to figure 1 , figure 2 , image 3 and Figure 4 , the adjustable non-return air valve 100 includes a valve body 1000 through which both ends pass through. In this embodiment, the material of the valve body 1000 is set according to the requirements of the actual application. As an exemplary material, the material of the valve body 1000 in this embodiment is metal, such as aluminum alloy, ordinary carbon steel, stainless steel, etc. . When the material of the valve body 1000 is ordinary carbon steel, it is preferable to provide an anti-corrosion layer on its surface. In this embodiment, the material of the valve body 1000 is set according to the requirements of the actual applica...

Embodiment 2

[0060] This embodiment provides an adjustable non-return air valve 100 , the adjustable non-return air valve 100 has one adjusting vane, that is, the adjustable non-return air valve 100 is a single-blade adjustable non-return air valve 100 .

[0061] Specifically, please also refer to figure 1 , figure 2 , image 3 and Figure 4 , the adjustable non-return air valve 100 includes a valve body 1000 through which both ends pass through. In this embodiment, the material of the valve body 1000 is set according to the requirements of the actual application. As an exemplary material, the material of the valve body 1000 in this embodiment is metal, such as aluminum alloy, ordinary carbon steel, stainless steel, etc. . When the material of the valve body 1000 is ordinary carbon steel, it is preferable to provide an anti-corrosion layer on its surface. In this embodiment, the material of the valve body 1000 is set according to the requirements of the actual application. As an exem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com