Layout method for optical fiber grating monitoring system for mine gas extraction

A fiber grating and gas drainage technology, which is applied in the direction of gas discharge, mining equipment, safety devices, etc., can solve problems such as poor ventilation, poor gas pollution, and poor underground environment, so as to improve resource utilization, The effect of high measurement accuracy and long signal transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

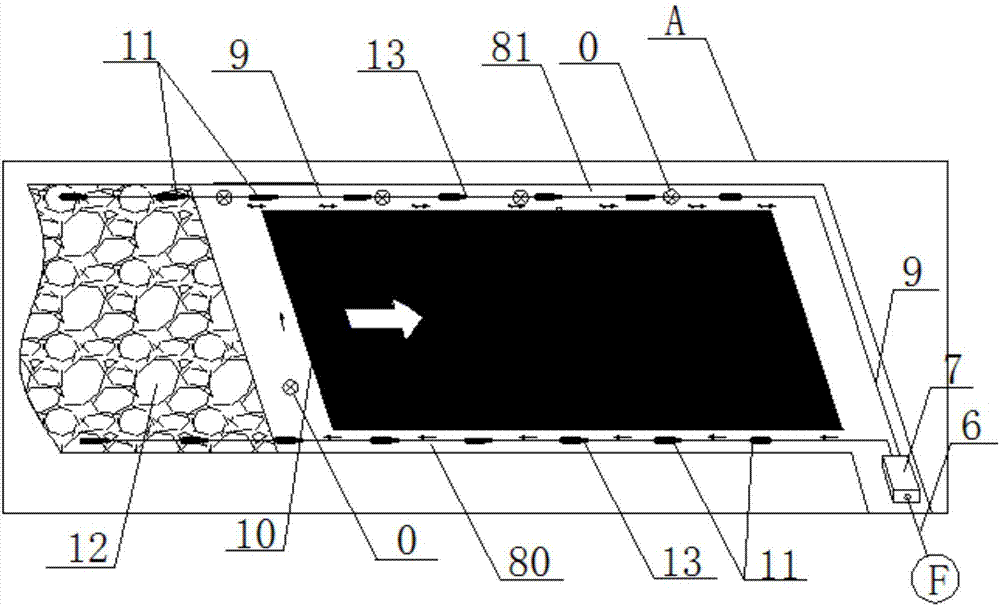

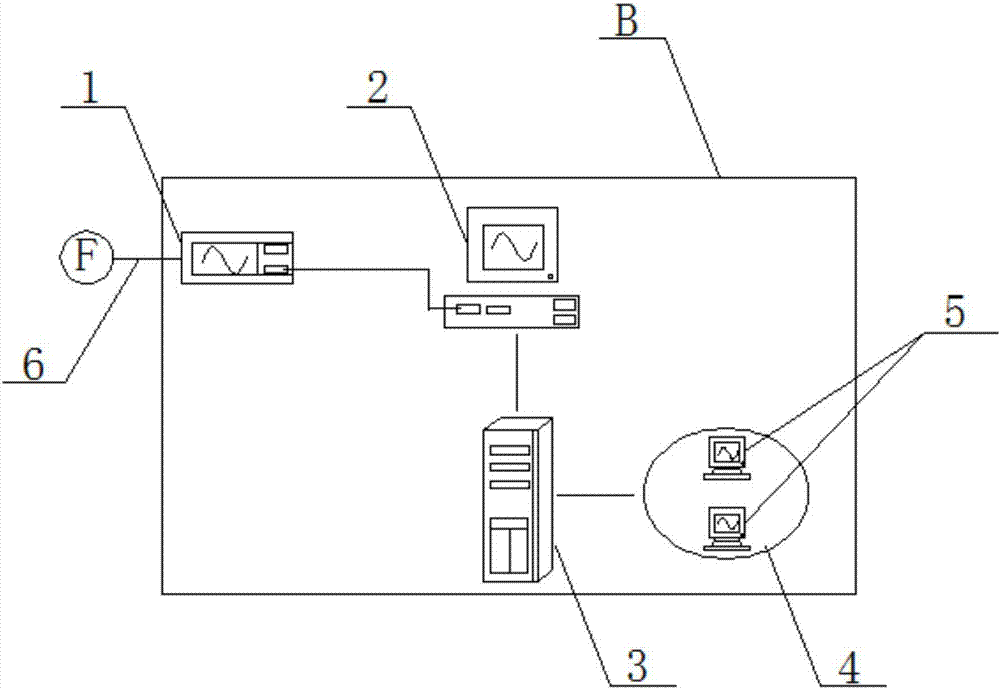

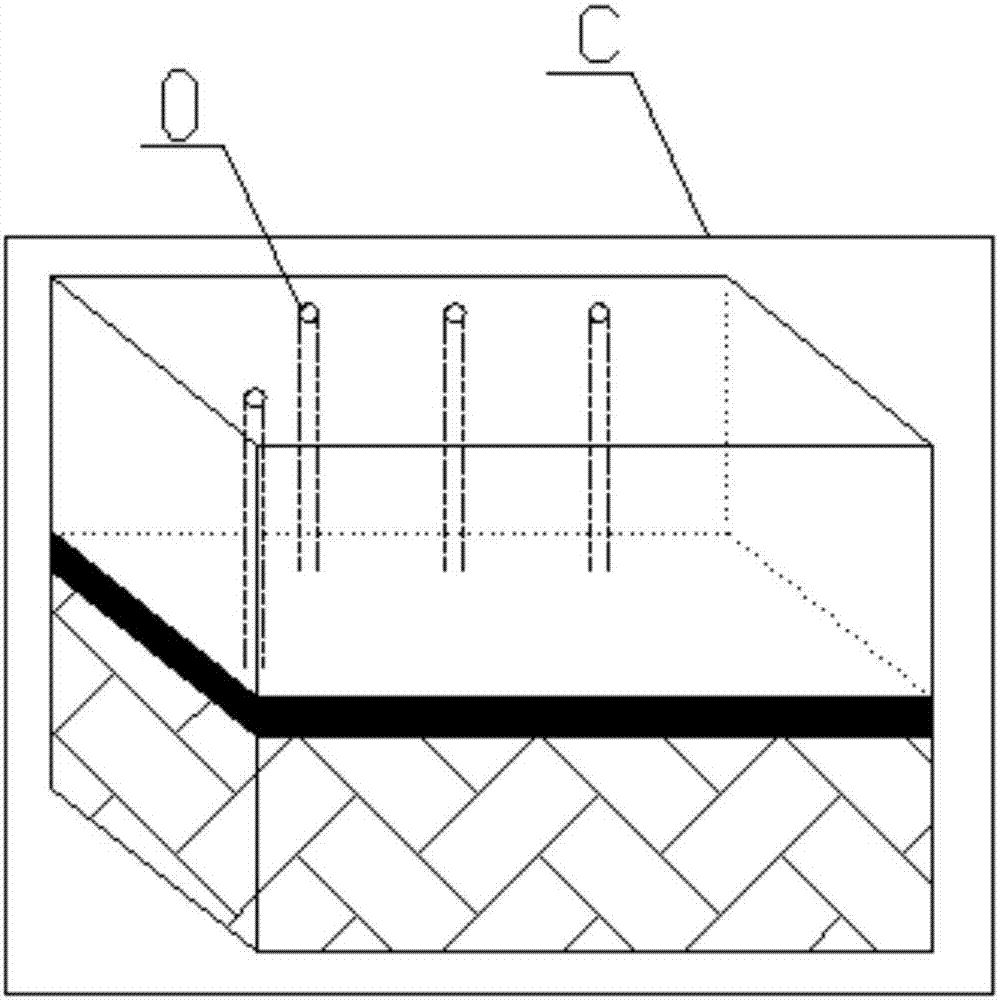

[0058] Embodiment 1: A fiber grating monitoring system layout method for gas drainage in high-gas mines. Fiber grating gas concentration sensors 11 are simultaneously deployed during the excavation of the transport lane 80 and the return air lane 81, and are installed on the top of the lane. The fiber grating gas concentration sensors 11 are arranged horizontally at intervals of 10-15m. Each fiber grating gas concentration sensor 11 is connected in series through the communication optical fiber 9, and the communication optical fiber 9 is connected with the mining transmission optical cable 6 through the optical fiber terminal box 7; the mining optical cable 6 is connected with the input end of the fiber grating static demodulator 1, and The output terminal of the controller 1 is connected to the monitoring computer 2, and the monitoring computer 2 performs data sharing with the client 5 through the network server 3 and the mine local area network 4; a gas drainage drilling grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com