Double-block type framework rail section assembling device and method for ensuring geometrical state of rails

An assembling device and two-block technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of rectification, difficulty in rectification, damage to the embedded sleeve, endangering the driving safety, etc. Uniform force and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

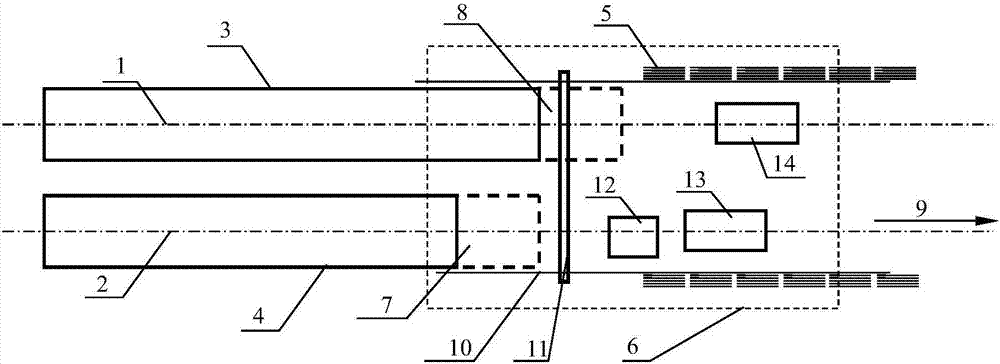

[0056] Embodiment 1: as Figure 1-Figure 9 As shown, a double-block frame-rail row assembly device that ensures the geometric state of the track includes an over-the-line gantry crane 11, a sleeper spreader 12, an automatic sleeper dividing device 14 and a tool rail frame spreader 13, and the over-the-line gantry crane 11 is placed on two On the track 10, the two tracks 10 are respectively fixedly connected to the casted ballastless track bed 3 on the left line and the cast ballastless track bed 4 on the right line, and the sleeper hanger 12 is detachably connected to the hook of the gantry crane 11 for hanging Hanging the sleeper, the tool cabinet frame hanger 13 is detachably connected to the hook of the gantry crane 11 for suspending the tool rail frame, and the automatic sleeper distribution device 14 is installed between the two tracks 10, arranged along the length direction of the track 10, It is used to automatically divide sleepers into multiple rows of sleepers.

[0...

Embodiment 2

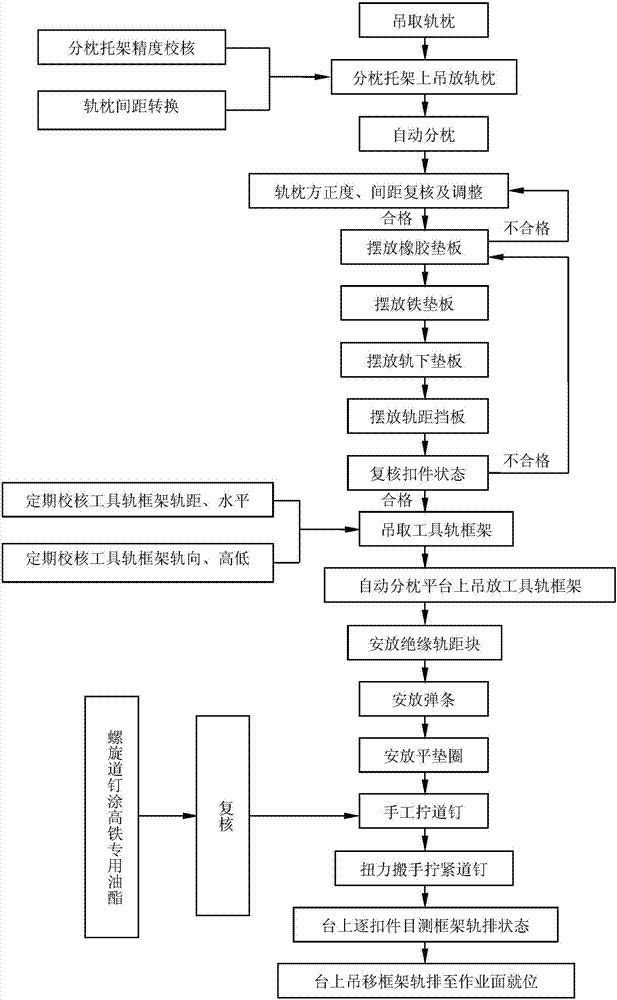

[0063] Embodiment 2: The above-mentioned double-block frame rail row assembly method to ensure the geometric state of the track adopts parallel and flowing construction operations: spiral spikes are painted with special oil for high-speed rail, tool rail frame accuracy checks, and sleeper bracket accuracy Parallel construction is used for checking, assembly of sub-sleepers on the platform and frame rail row; flow construction is used for assembly of sub-sleepers and frame rail row, and 10t cross-line gantry crane is used to lift vertically and horizontally the sleepers on the construction work surface, and 5 sleepers are lifted each time Sleepers, every 10 sleepers on the sub-sleeper platform are assembled into a frame rail row, the sleeper spacing is adjusted by pre-adjusting the spacing of the sleeper platform on the sub-sleeper bracket, and the sub-sleeper driving device pulls the wire rope to pull the sub-sleeper bracket to open for automatic sleeper distribution The tool r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com