Structure for fixing wheel arch molding

A technology for fixing structures and moldings, applied in the direction of upper structure, upper structure sub-assembly, connecting components, etc., can solve the problem of small wheel track, achieve small size in the width direction of the vehicle, ensure wheel track, and improve aesthetics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be described based on examples of the present invention shown in the drawings.

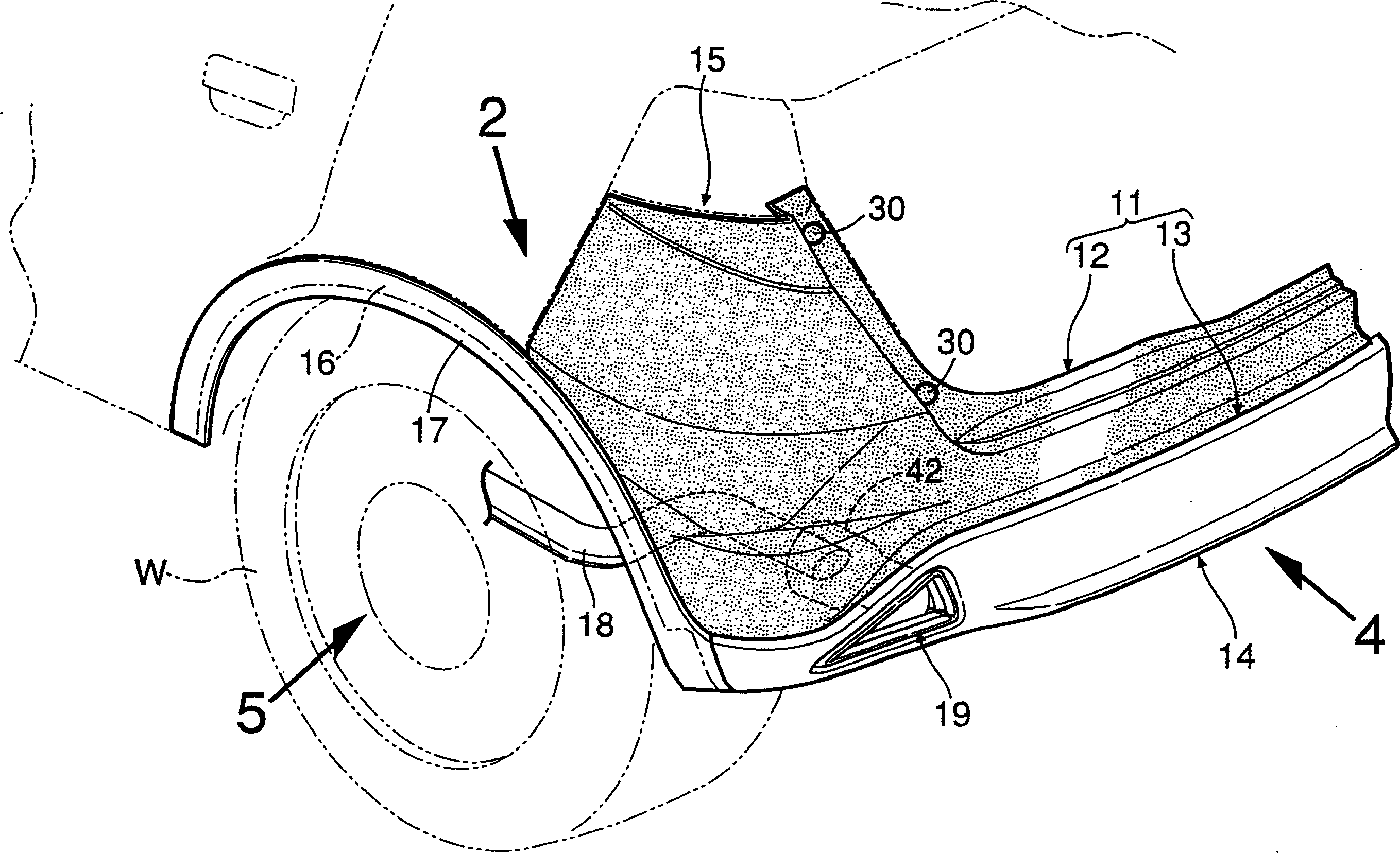

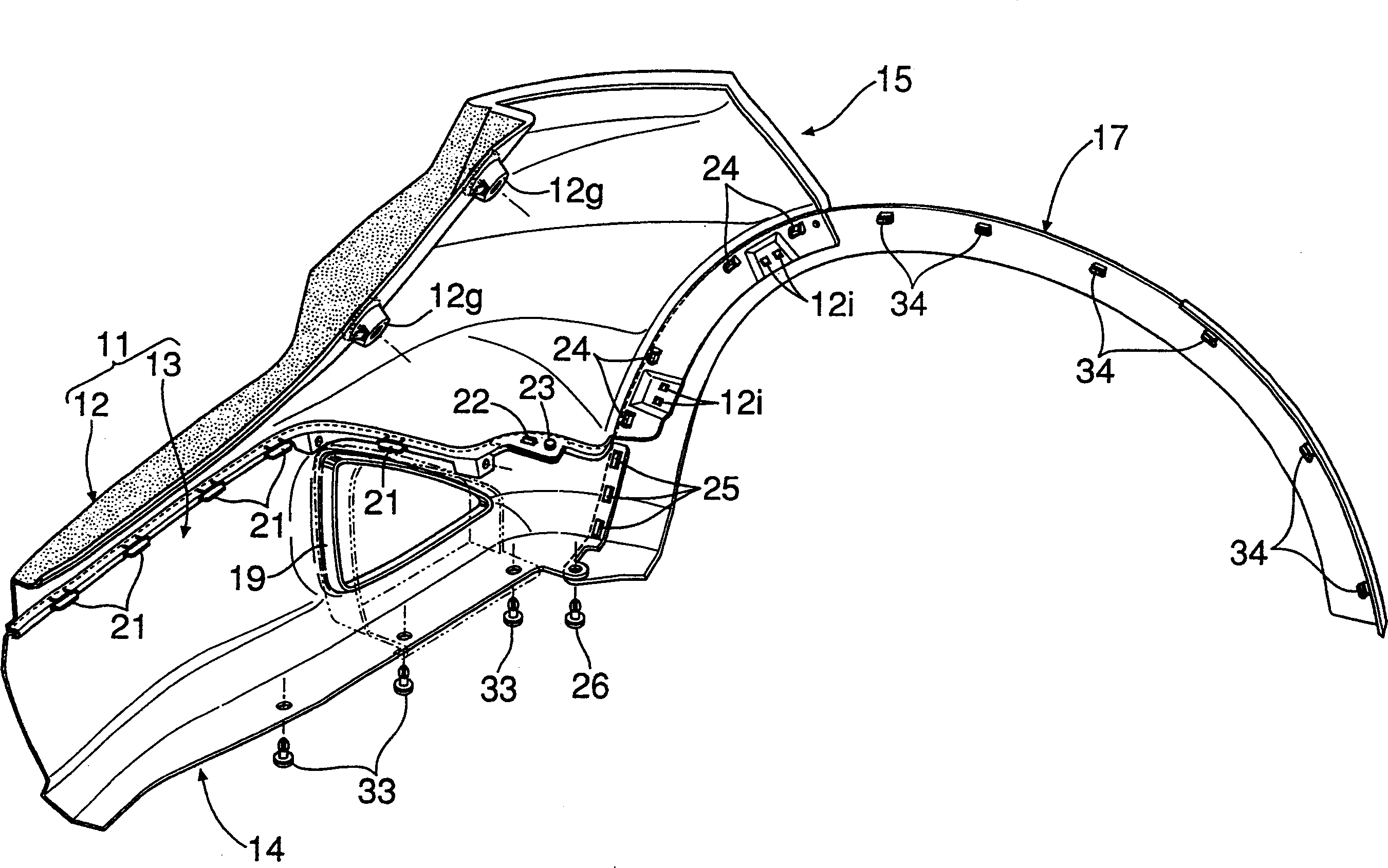

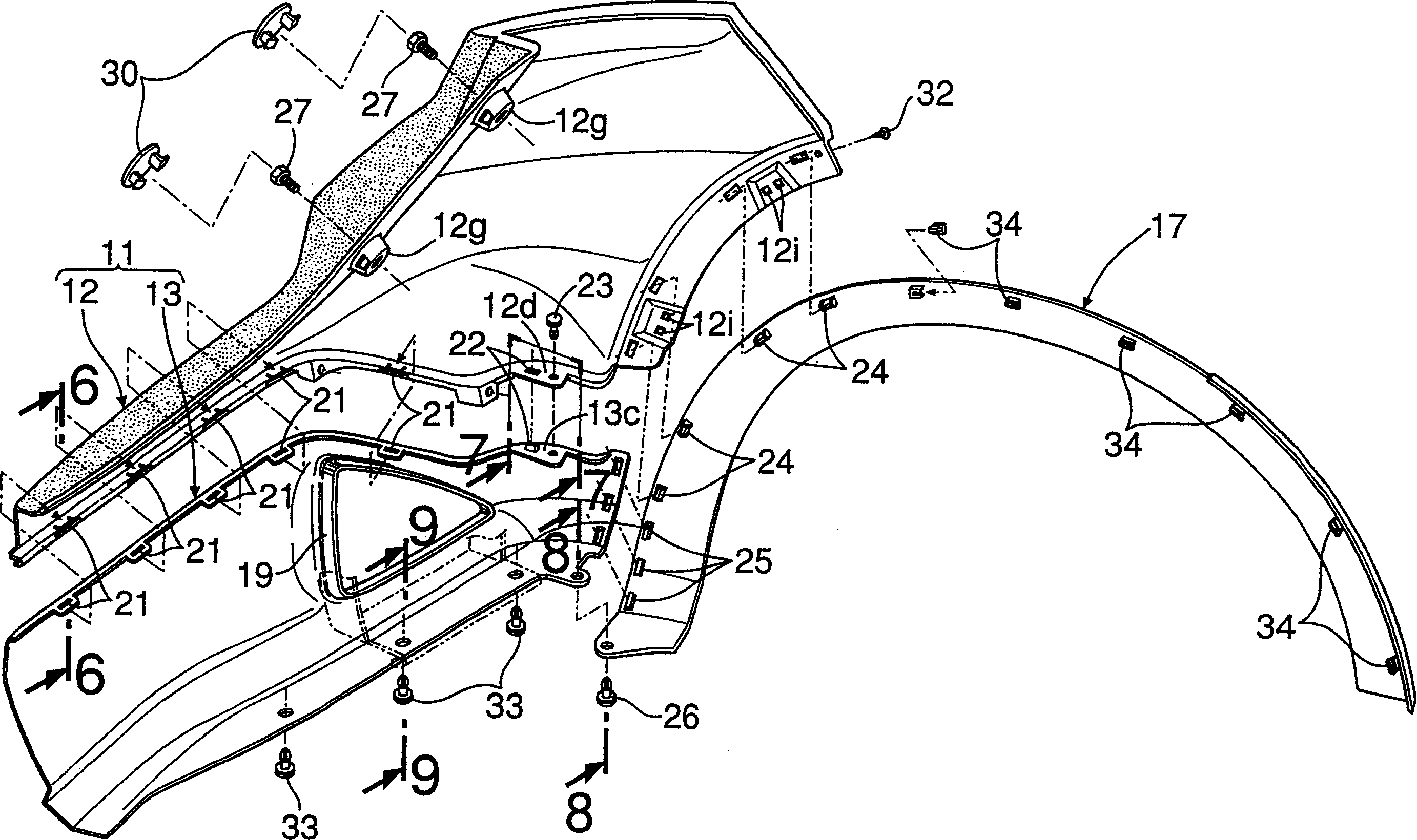

[0024] Figure 1 to Figure 15 Represents an embodiment of the present invention, figure 1 It is a perspective view of the left half of the rear bumper. figure 2 yes figure 1 Arrow 2 to the view. image 3 With figure 2 The corresponding exploded perspective view. Figure 4 yes figure 1 Arrow 4 to the view. Figure 5 yes figure 1 Arrow 5 to the view. Figure 6 is along image 3 An enlarged cross-sectional view of the 6-6 line section. Figure 7 is along image 3 An enlarged cross-sectional view of the 7-7 line cut. Figure 8 is along image 3 An enlarged cross-sectional view of the 8-8 line section. Figure 9 is along image 3 An enlarged cross-sectional view of the 9-9 line cut. Figure 10 is along Figure 4 An enlarged sectional view of the 10-10 line cut. Figure 11 yes Figure 5 Enlarged sectional views of each pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com