Preparation and application of bisphenol A disalicyate in anti-aging foamed material

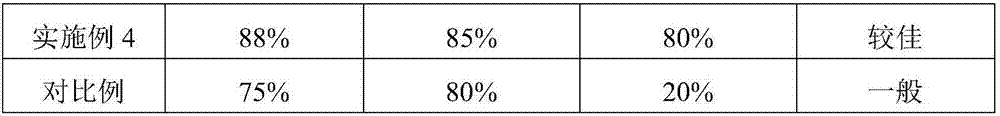

A technology of bisphenol salicylate and foaming materials, which is applied in the field of foaming material additives to achieve the effects of prolonging the service life and durability of appearance aesthetics, broadening the absorption wavelength, and good full-wavelength anti-ultraviolet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation of bisphenol A disalicylate comprises the steps:

[0020] (1) Mix ethyl salicylate and bisphenol A in a mass ratio of 3:10 and heat to 80°C;

[0021] (2) Add the catalyst monobutyl stannoic acid, continue heating to 135°C, the reaction time is 3h, the addition amount of monobutyl stannic acid is half of the amount of ethyl salicylate, dissolve the product with absolute ethanol, wash and dry to obtain bis Crude product of bisphenol A salicylate;

[0022] (3) The crude product of bisphenol A disalicylate, carbon black, 2,4-dihydroxybenzophenone, and the antioxidant are mixed in a mass ratio of 4:1:2:1, heated to After maintaining at 50° C. for 1 hour, the product is subjected to low-temperature plasma modification treatment to obtain modified bisphenol A disalicylate; the antioxidant is preferably trialkylphenol.

Embodiment 2

[0024] The preparation of bisphenol A disalicylate comprises the steps:

[0025] (1) Mix ethyl salicylate and bisphenol A in a mass ratio of 3:10 and heat to 90°C;

[0026] (2) Add the catalyst monobutyl stannoic acid, continue heating to 140°C, the reaction time is 3.5h, the addition amount of monobutyl stannic acid is half the amount of ethyl salicylate, dissolve the product with absolute ethanol, wash, dry, and obtain Crude product of bisphenol A disalicylate;

[0027] (3) The crude product of bisphenol A disalicylate, carbon black, 2,4-dihydroxybenzophenone, and the antioxidant are mixed in a mass ratio of 4:1:2:1, heated to After maintaining at 60° C. for 2 hours, the product is subjected to low-temperature plasma modification treatment to obtain modified bisphenol A disalicylate; the antioxidant is preferably trialkylphenol.

Embodiment 3

[0029] The preparation of bisphenol A disalicylate comprises the steps:

[0030] (1) Mix ethyl salicylate and bisphenol A in a mass ratio of 3:10 and heat to 85°C;

[0031] (2) Add the catalyst monobutyl stannoic acid, continue heating to 138°C, the reaction time is 3.3h, the amount of monobutyl stannic acid added is half of the amount of ethyl salicylate, dissolve the product with absolute ethanol, wash, dry, and obtain Crude product of bisphenol A disalicylate;

[0032] (3) The crude product of bisphenol A disalicylate, carbon black, 2,4-dihydroxybenzophenone, and the antioxidant are mixed in a mass ratio of 4:1:2:1, heated to After maintaining at 55° C. for 1.5 h, the product is subjected to low-temperature plasma modification treatment to obtain modified bisphenol A disalicylate; the antioxidant is preferably trialkylphenol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com