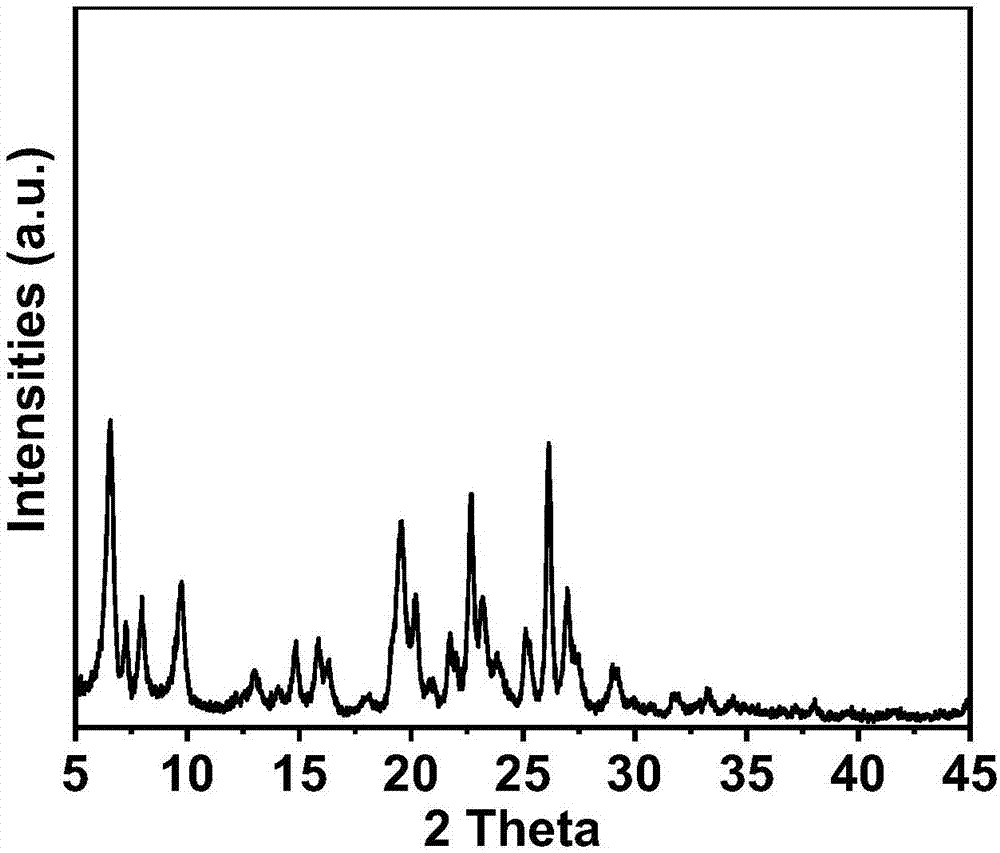

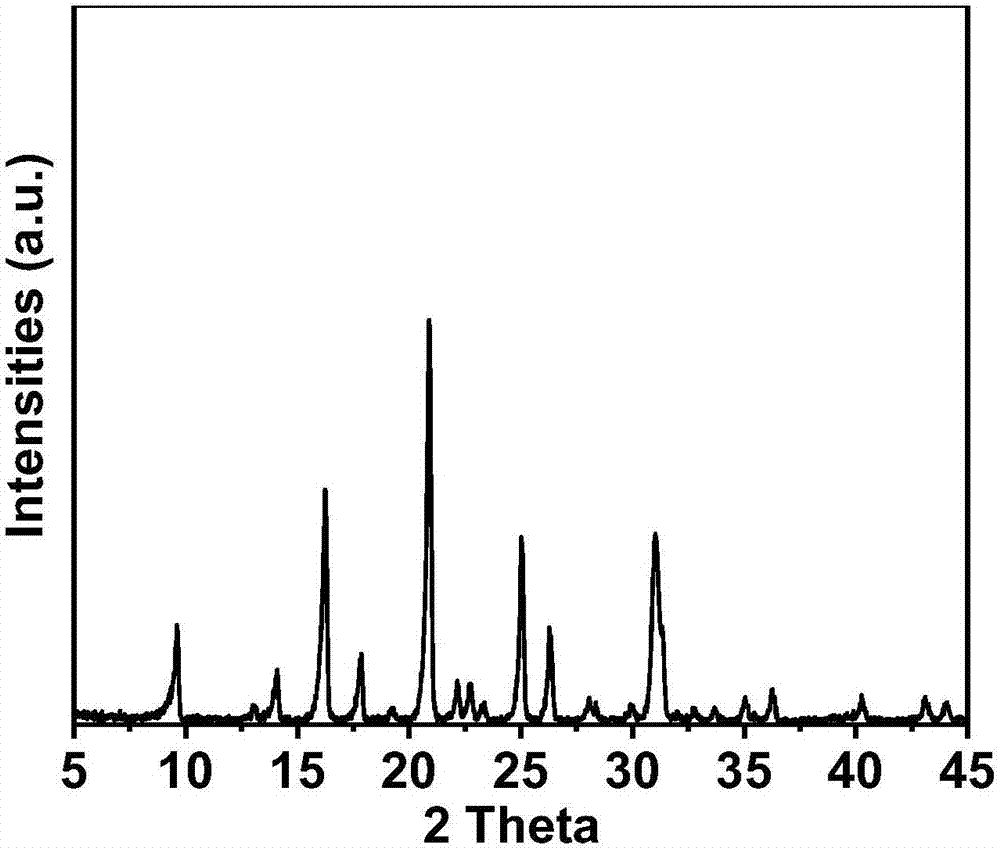

Rapid synthesis method for high-purity zeolite molecular sieve

A zeolite molecular sieve, high-purity technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as poor repeatability, and achieve the effect of high crystallinity and simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of method for rapidly synthesizing high-purity zeolite molecular sieve that the present invention proposes, comprises the following steps:

[0027] S1. Mix N,N,N-trimethyl-1-adamantyl ammonium hydroxide with deionized water, stir, then add aluminum source, then add tetraethyl orthosilicate to obtain initial gel mixture, and then The initial gel mixture is thermostated and cooled;

[0028] S2. The product obtained in S1 is washed, dried, and then calcined to obtain a high-purity zeolite molecular sieve.

Embodiment 2

[0030] A kind of method for rapidly synthesizing high-purity zeolite molecular sieve that the present invention proposes, comprises the following steps:

[0031] S1. Mix 11.5 parts by weight of N,N,N-trimethyl-1-adamantyl ammonium hydroxide with 2 parts of deionized water, stir magnetically for 4 minutes, then add 0.1 part of aluminum source, continue stirring for 25 minutes, and then Add 4 parts of tetraethyl orthosilicate, continue to stir for 4 minutes to obtain the initial gel mixture, and then carry out constant temperature treatment at 150°C for 7 days;

[0032] S2. The product obtained in S1 was washed with deionized water, dried at 85° C., and then calcined at 540° C. for 8.5 hours to obtain a zeolite molecular sieve.

Embodiment 3

[0034] A kind of method for rapidly synthesizing high-purity zeolite molecular sieve that the present invention proposes, comprises the following steps:

[0035] S1. Mix 13.5 parts by weight of N,N,N-trimethyl-1-adamantyl ammonium hydroxide with 3 parts of deionized water, stir magnetically for 7 minutes, then add 0.5 parts of aluminum source, continue stirring for 35 minutes, and then Add 4 parts of tetraethyl orthosilicate, continue to stir for 7 minutes to obtain the initial gel mixture, and then carry out constant temperature treatment at 170°C for 5 days;

[0036] S2. The product obtained in S1 was washed with deionized water, dried at 95° C., and then calcined at 570° C. for 7.5 hours to obtain a zeolite molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com