A mobile granular material loading and conveying device

A technology for granular materials and conveying devices, applied in conveyors, loading/unloading, transportation and packaging, etc., can solve the problems of narrow internal space, increased pressure drop in the device, affecting the mass transfer effect, etc., to achieve low labor intensity, The effect of reducing labor intensity and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

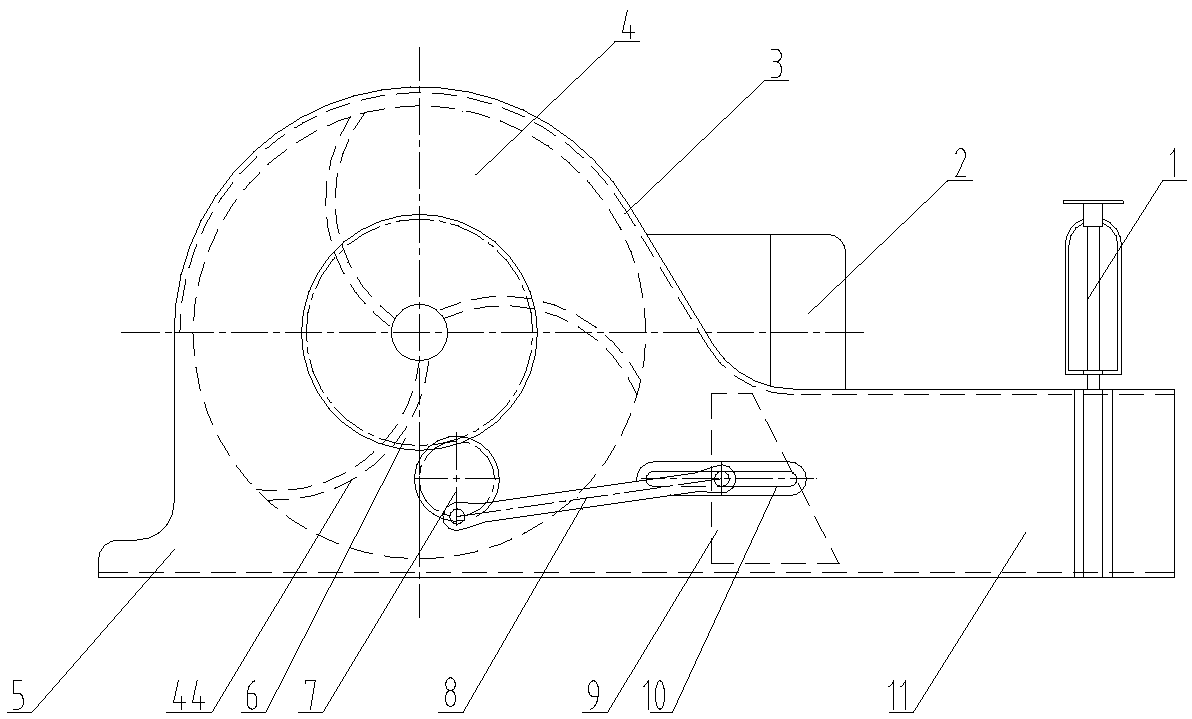

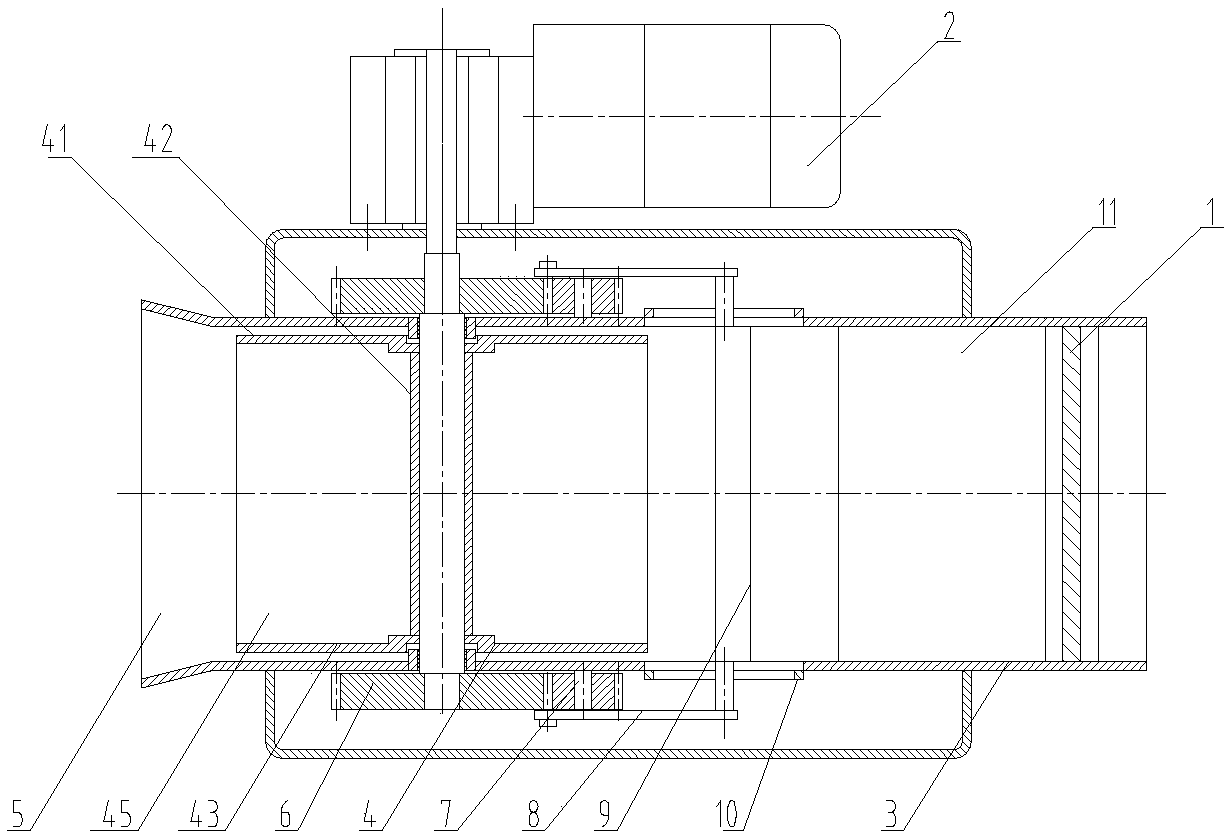

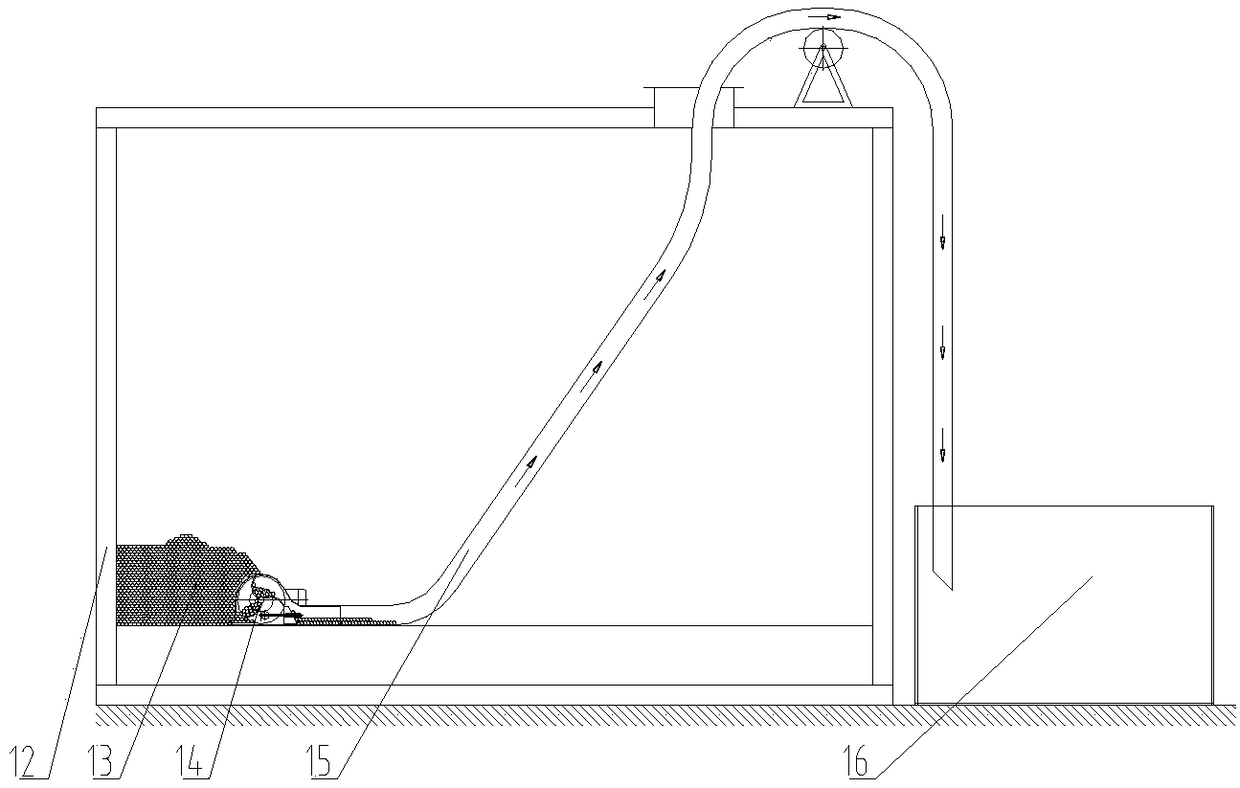

[0017] like Figure 1-4 As shown, the mobile granular material loading and conveying device provided by the present invention includes a housing 3 , a driving device 2 fixed on the housing 3 , a bucket wheel 4 installed in the housing 3 , a pushing mechanism and a valve 1 . In this embodiment, the valve 1 adopts a check valve, and the bucket wheel 4 is a wheel structure, including a left side plate 41 and a right side plate 43 oppositely arranged and a bushing 42 between them, and the bushing 42 The outer peripheral wall is equidistantly radiated along its center line to form an arc-shaped partition 44, and the space surrounded by two adjacent arc-shaped partitions 44, the wall surface of the left side plate 41 and the right side plate 43 and the outer peripheral wall of the shaft sleeve 42 becomes The material fetching part 45 (digging bucket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com