New Hump full electronic automation system integrating control, supervision and monitoring

An automation system and hump technology, applied in the direction of automatic systems, etc., can solve problems such as insufficient optimization of the system network structure, inconvenient networking to exchange information, long fault recovery time, etc., to achieve high safety and reliability, simple structure, and fault recovery fast time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

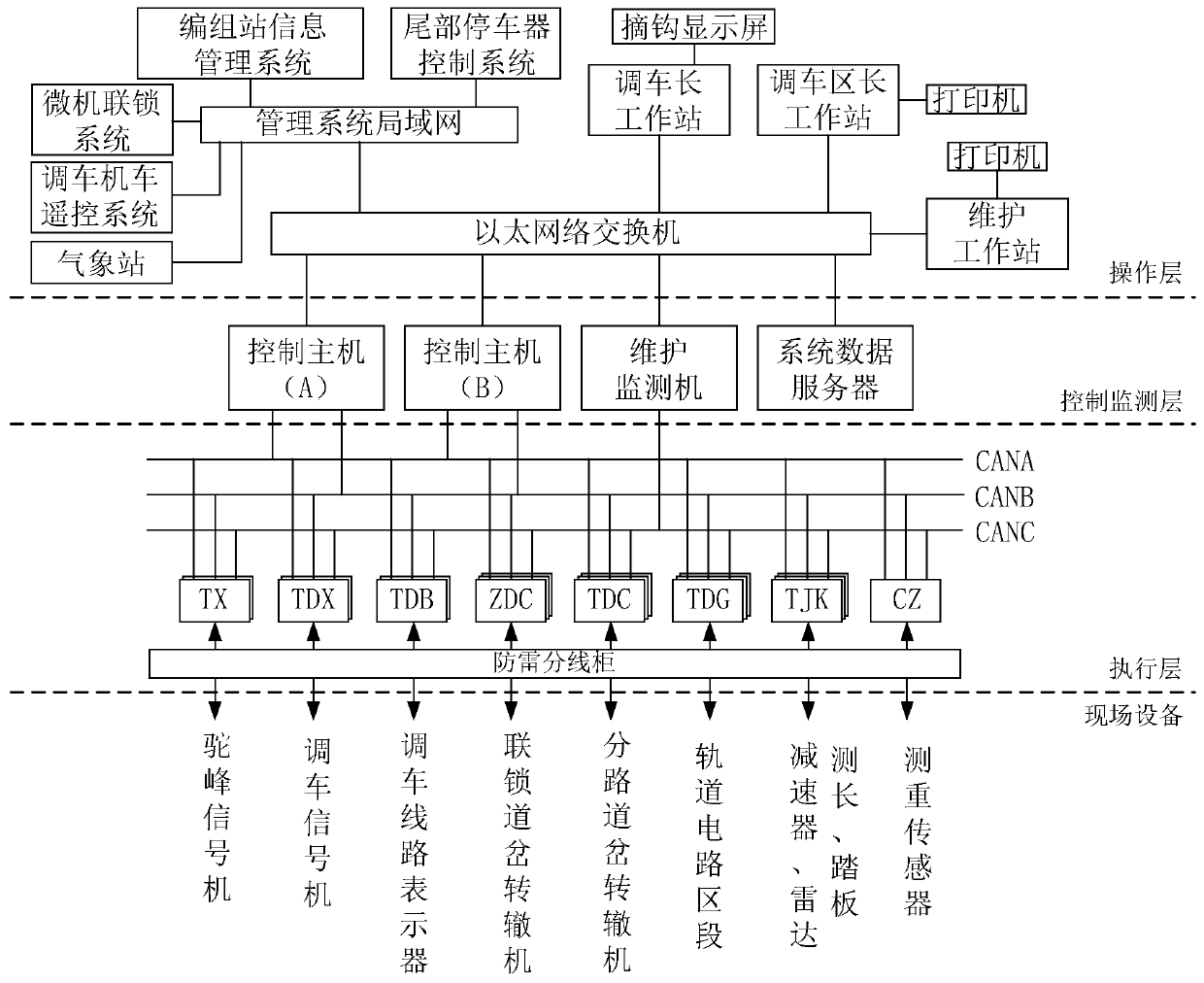

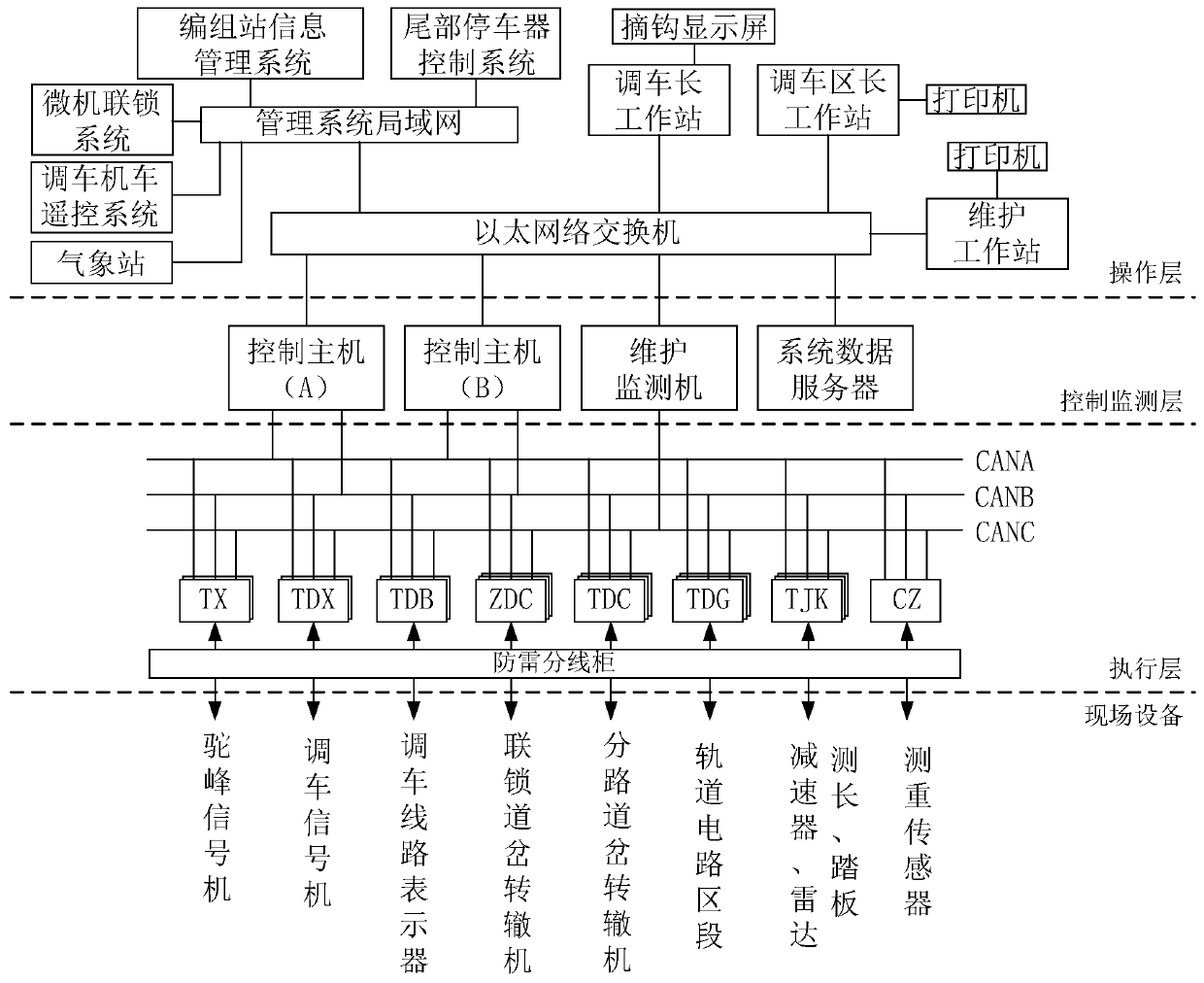

[0027] The present invention provides a novel control, supervision and monitoring integrated hump full electronic automation system. The hump full electronic automation system includes:

[0028] The operation layer is used to set up multiple workstations according to the scale of the station, operations and user needs, including: shunting chief workstation, shunting chief workstation, maintenance workstation, etc.;

[0029] Monitoring layer, including two main control machines, system data server, maintenance monitoring machine;

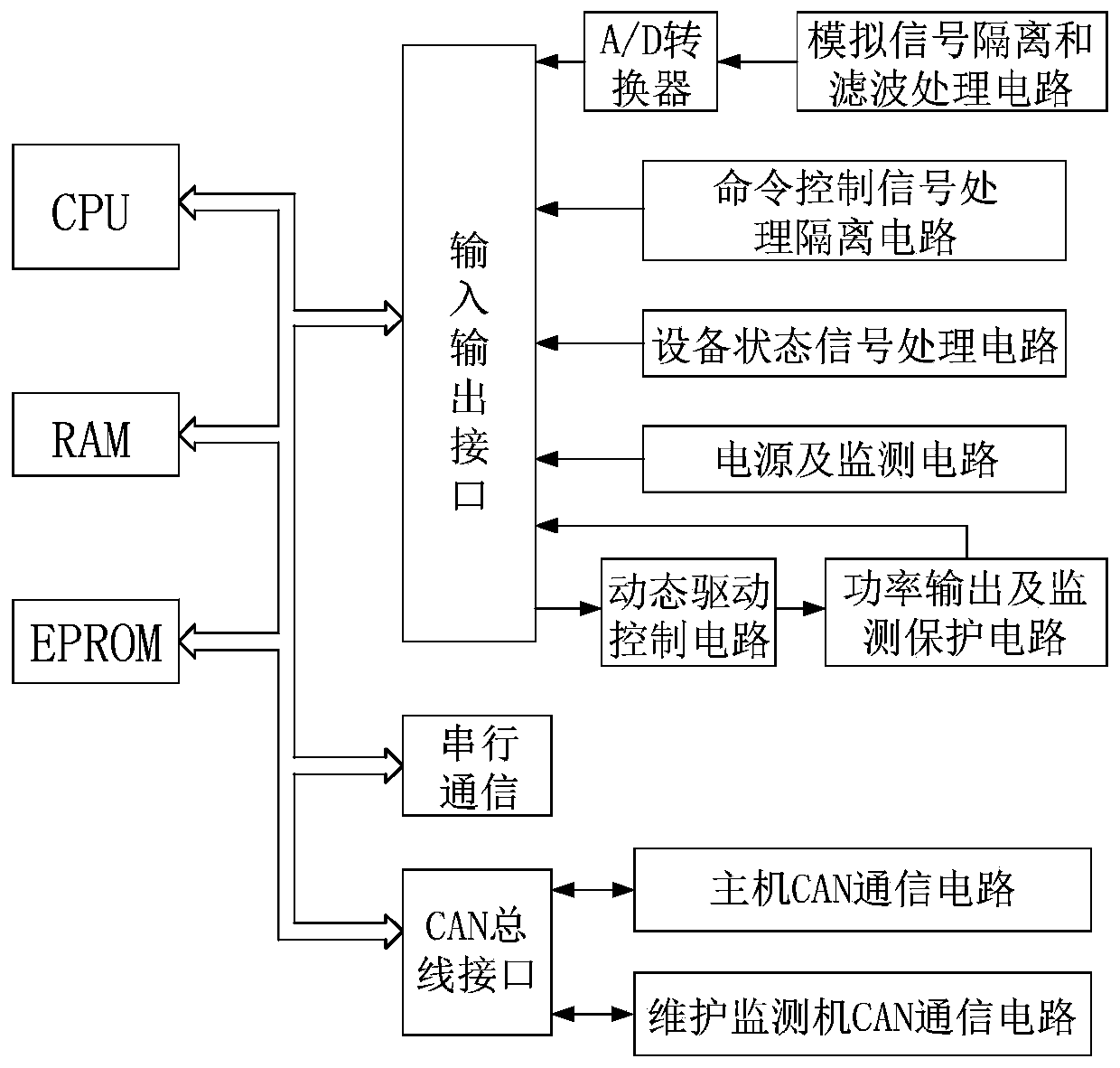

[0030]The execution layer is composed of a group of all-electronic intelligent execution cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com