SCARA robot special for screw assembly

A robot and screw technology, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of insufficient flexibility, affecting the working accuracy and stability of robots, and achieve the effects of high flexibility, rich application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention simple and clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention. Invention is not intended to limit the present invention.

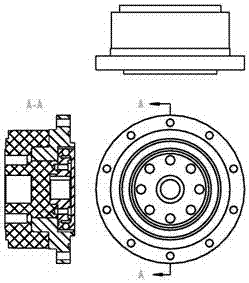

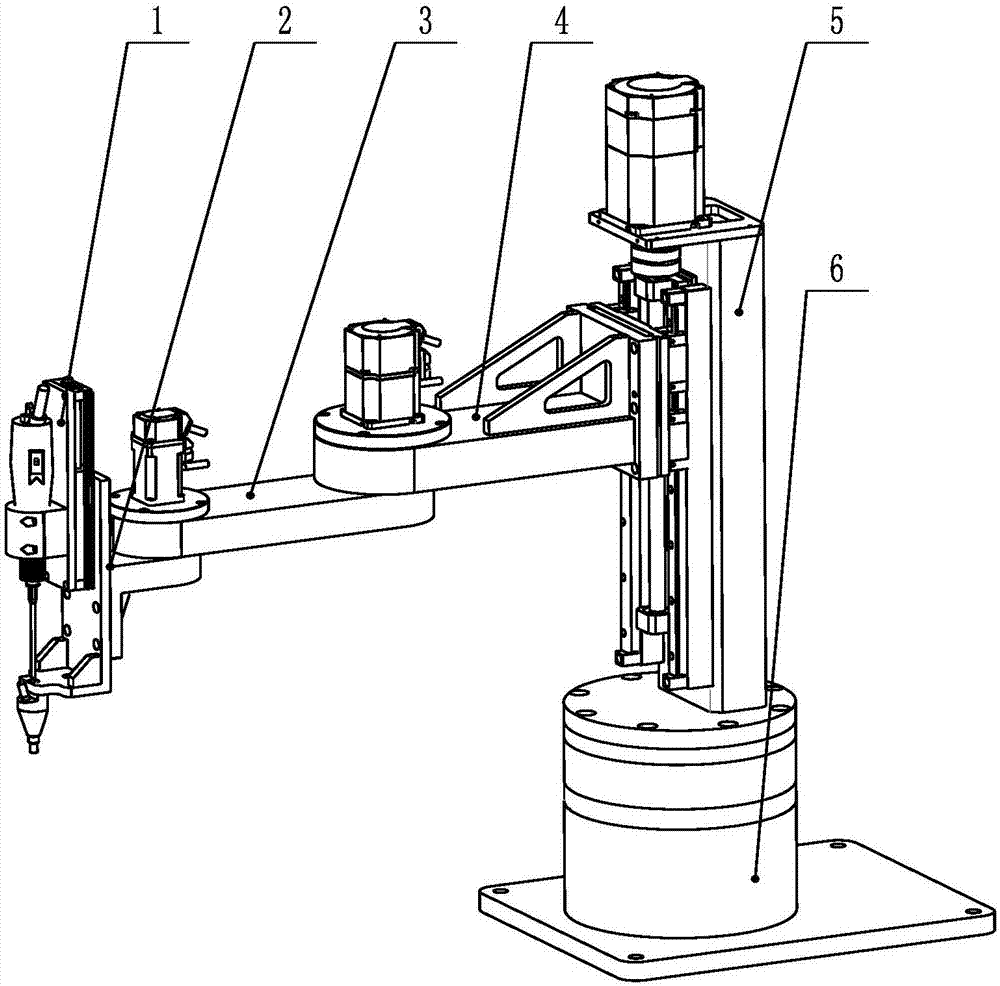

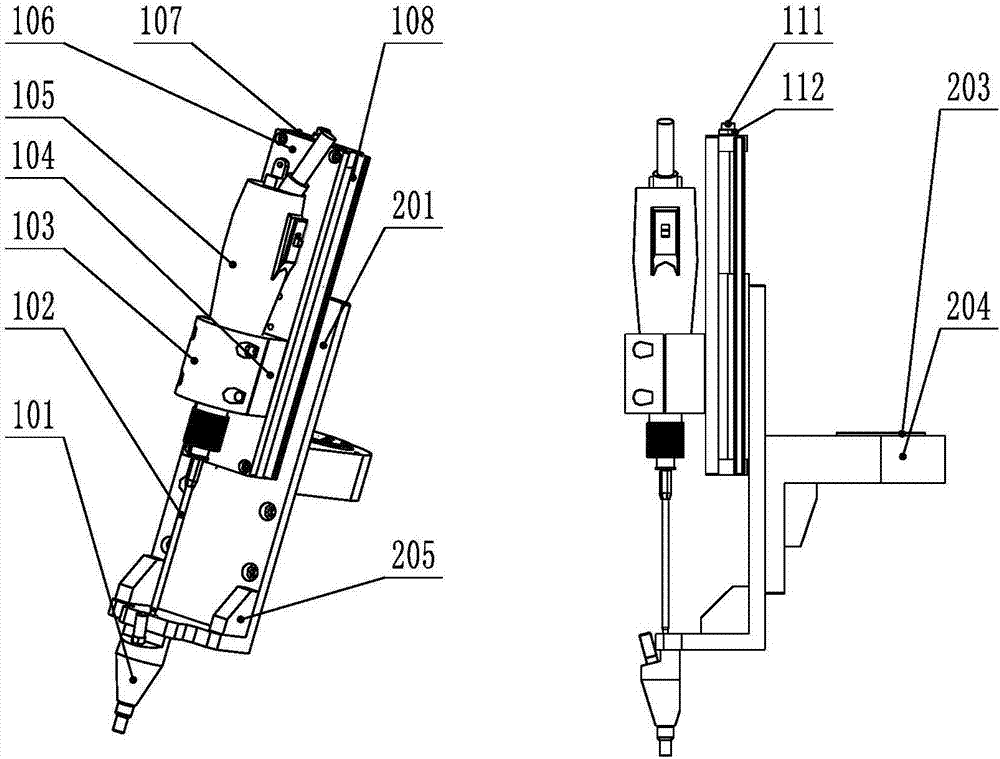

[0019] See attached Figure 1-9 , The present invention provides a special SCARA robot for screw assembly, which is composed of an end effector 1, a wrist 2, an elbow 3, a shoulder 4, a shoulder lifting mechanism 5 and a machine base 6, etc. The end effector 1 is composed of a screw back groove nozzle 101, a screwdriver 102, an end cover 103, a bottom cover 104, an electric drill 105, a lifting frame moving plate 106, a lifting frame top cover 107, a lifting frame outer support rod 108, a lifting frame The frame sliding shaft 109, the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com