A method of welding modular steel frames using a rotating device

A rotating device and steel frame technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult quality control of assembly welding, large hidden dangers of operation safety, high cost and high cost, so as to achieve safe rotation and ensure the quality of assembly welding , The effect of high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A method for welding a modular steel frame using a rotating device, comprising the following steps:

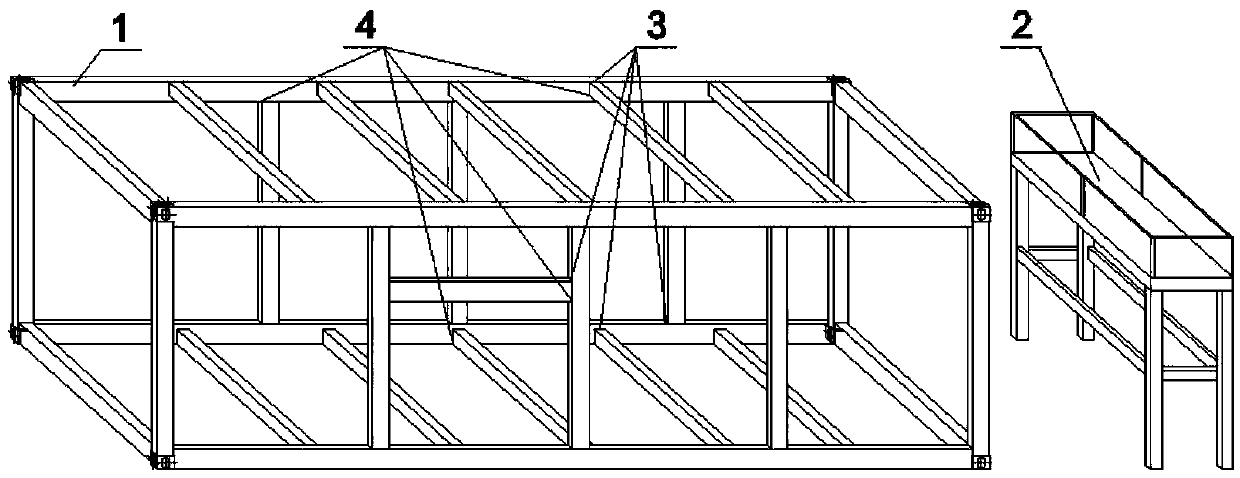

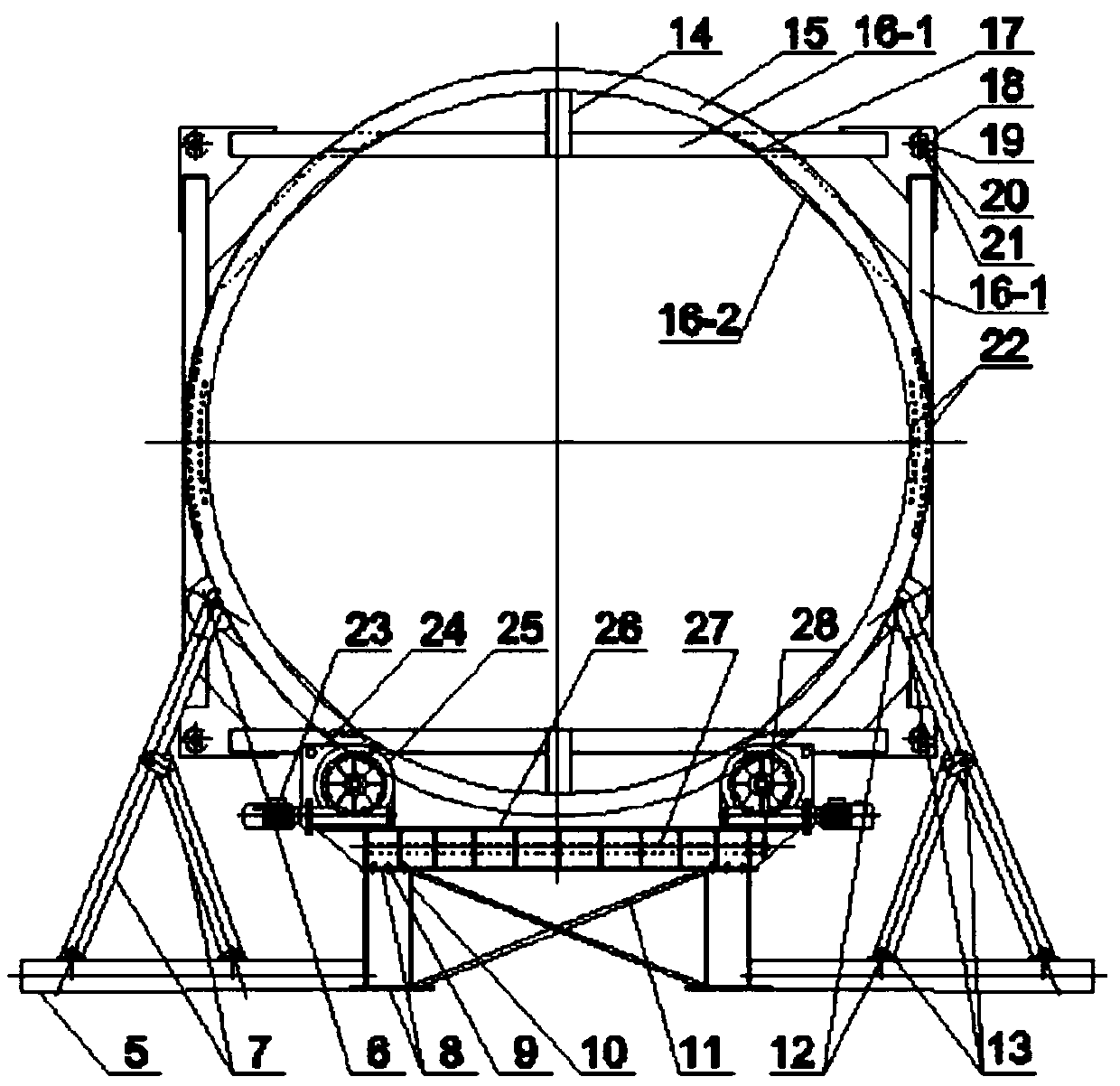

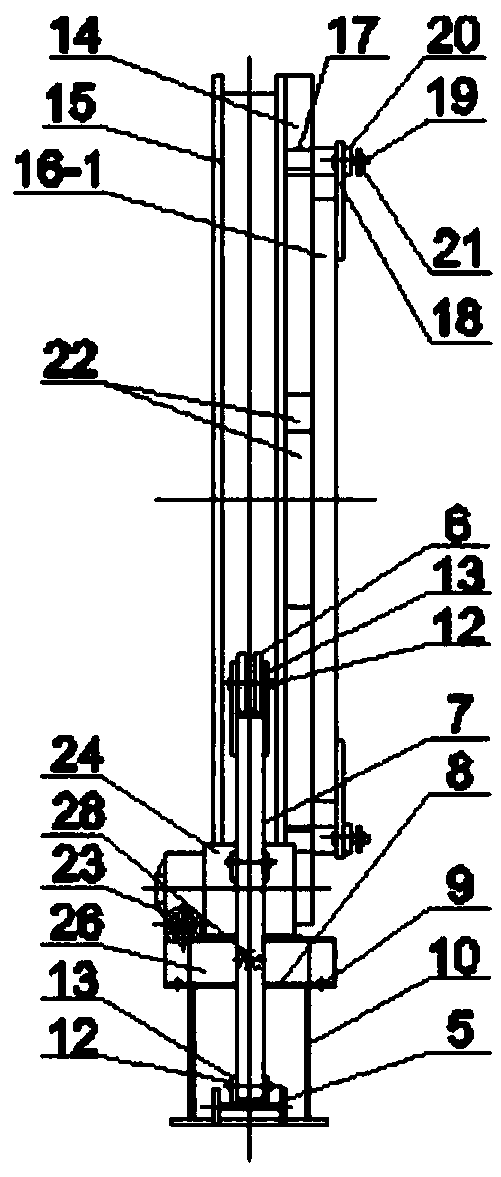

[0047] 1. Make the rotating device: such as figure 2 , 3 As shown: the rotating device is composed of a side support frame part, an electric roller frame part and a fixed connection support part.

[0048] ① if Figure 4 , 5 As shown: the lateral support frame part is composed of two sets of support devices, each set of support devices includes a vertically arranged H-shaped steel bracket 10, an I-shaped steel base 5 connected horizontally with the H-shaped steel bracket, and passive rollers 6 and I-shaped steel A rectangular steel pipe support rod 7 is connected between the bases 5, and the support rod is fixedly connected to the I-shaped steel base and the passive roller through the fixed pin 12, and the passive roller 6 is rolled and supported on the circular roller under the action of the rectangular steel pipe support rod 7 The two sides of the track 15 prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com