Drilling tool effectively avoiding damage of cutting edge

A technology for drilling tools and cutting edges, which is applied in drilling tool accessories, manufacturing tools, drill repairing, etc. It can solve problems that affect the smooth production, easy chipping, scrapped blades, etc., so as to avoid easy chipping and improve the service life of the blades. , to avoid the effect of extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

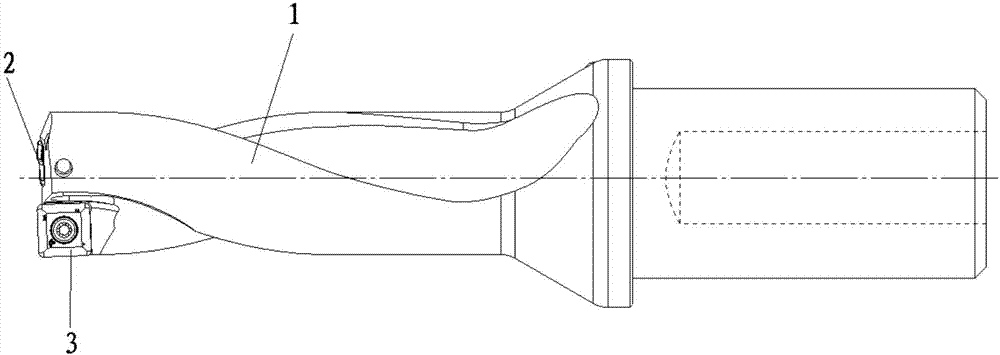

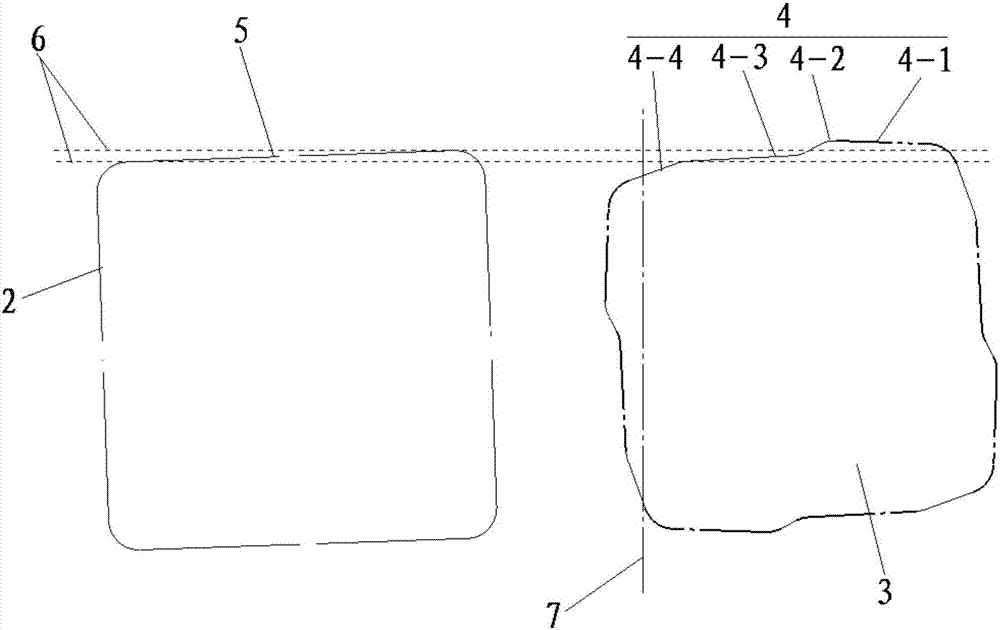

[0015] In order to provide a drilling tool that effectively avoids edge damage, such as Figure 1 to Figure 3 As shown: the drilling tool includes a drill body 1, an inner blade blade 2 and an outer blade blade 3, the inner blade blade 2 and the outer blade blade 3 are all connected to the drill body 1, the inner blade blade 2 is provided with an inner blade 4, and the outer blade blade 2 The outer edge 5 is arranged on the edge blade 3; the surface perpendicular to the axis of the drill body 1 is the drill cutting surface 6; the inner edge 4 includes a first inner edge segment 4-1, a second inner core segment 4-3 and a third inner edge Segment 4-4; the frontmost part of the first inner blade segment 4-1 is the centering point 4-2, and the first inner blade segment 4-1 extends outward and rearward from the centering point 4-2; the third inner b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com