Button structure

A technology of buttons and bottom plates, which is applied in the direction of contact drive mechanism, electrical components, electric switches, etc. It can solve the problems of poor touch and pressure feel of the button structure, weakened structural strength of the button structure, and easy damage, etc., to improve the touch and pressure feel, The effect of reducing thickness and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

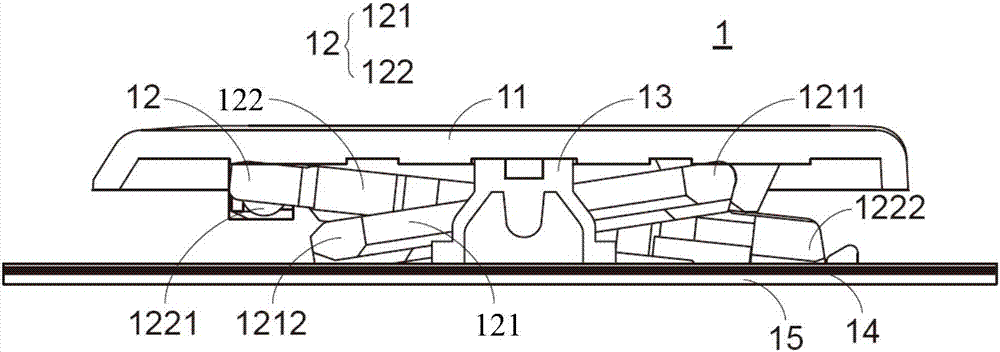

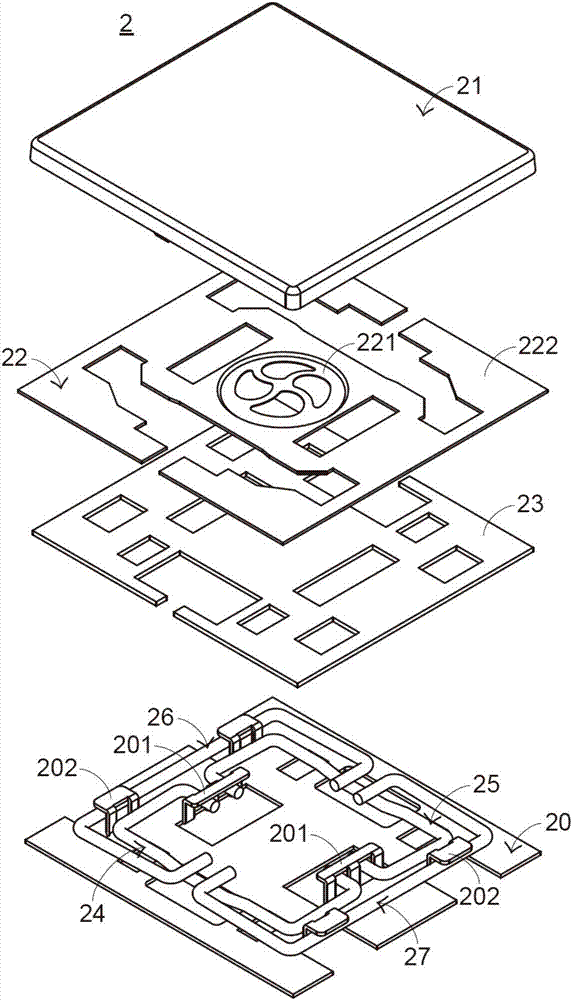

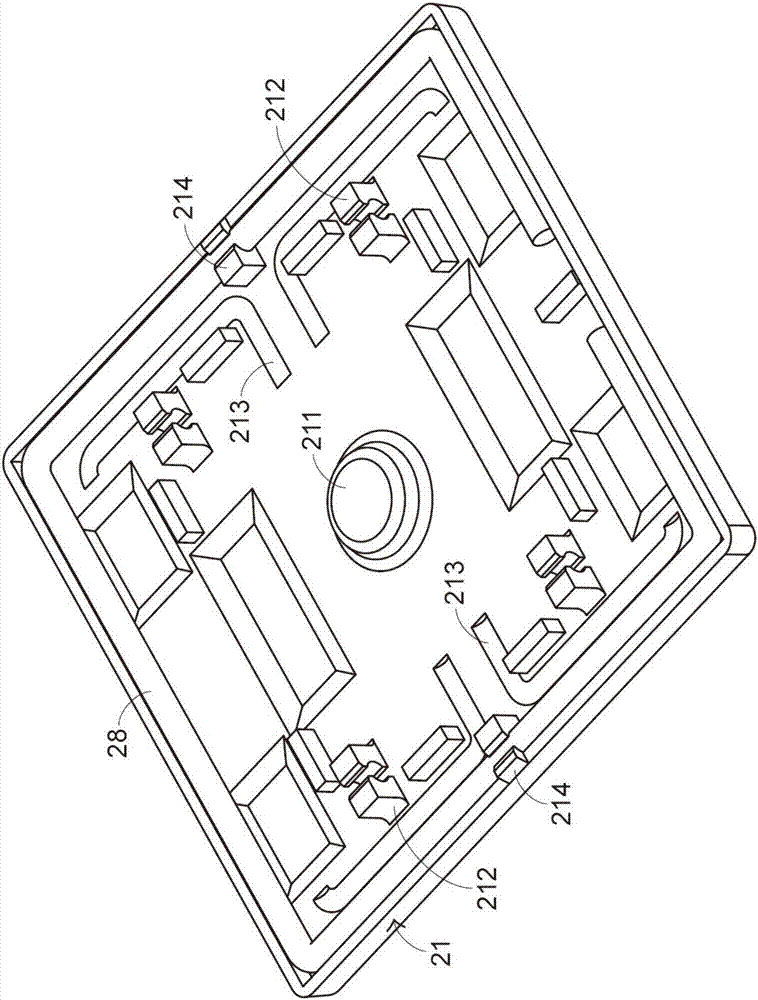

[0030] The invention provides a button structure that can give users a good touch and pressure feeling, and can maintain a light and thin shape, so as to solve the problems existing in the prior art. Please also see figure 2 as well as image 3 , figure 2It is a structural exploded schematic diagram of the button structure of the present invention in a preferred embodiment, and image 3 It is a structural schematic diagram of another viewing angle of the key cap of the key structure of the present invention in a preferred embodiment. The key structure 2 includes a bottom plate 20, a key cap 21, an elastic element 22, a membrane switch circuit 23, a first longitudinal link 24, a second longitudinal link 25, a first transverse link 26, a second transverse link 27 and a surrounding link. Rod 28. The key cap 21 is located above the bottom plate 20 and can move relative to the bottom plate 20. The key cap 21 includes a protruding portion 211, a plurality of first key cap hook...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com