Method for improving efficiency of gas drainage liquid ring vacuum pump through macromolecular drag reduction agent

A liquid ring vacuum pump and gas drainage technology, which is applied in gas discharge, pump, pump components and other directions, can solve the problems of high failure rate, low efficiency of gas drainage liquid ring vacuum pump, and high energy consumption, and achieves large pumping capacity and energy saving. Remarkable effect, good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

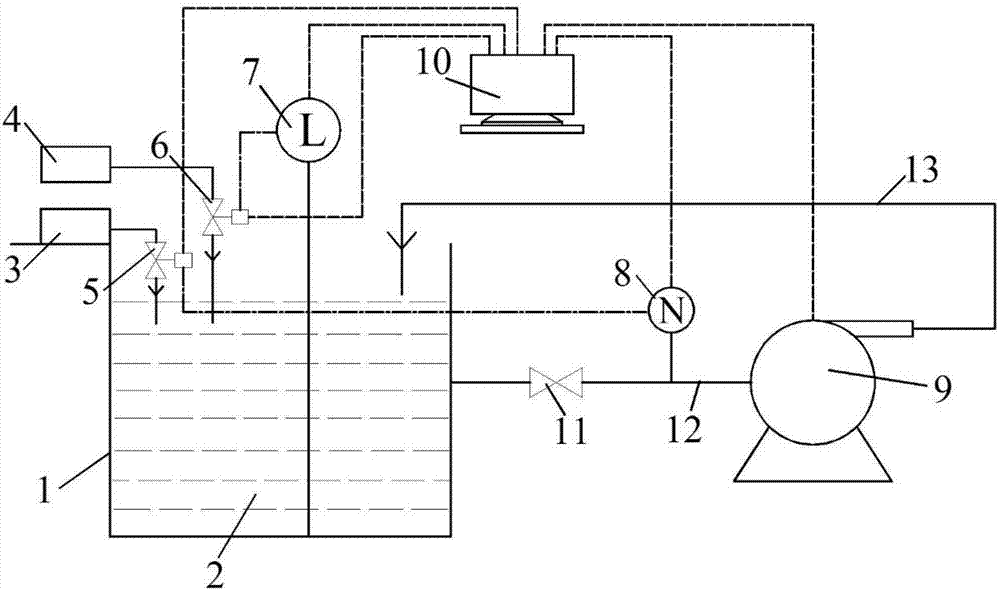

[0026] like figure 1 As shown, a method for improving the efficiency of a liquid ring vacuum pump for gas drainage by using a polymer drag reducer includes the following steps:

[0027] a. Prepare high-concentration and low-concentration polymer drag reducer solutions. The concentration range of high-concentration solution is 3-5%, and the concentration range of low-concentration solution is 0.5‰~6‰. The solutions are respectively loaded into the high and low concentration drag reducing agent filling machines;

[0028] b. Use a high-concentration drag-reducing agent filling machine to continuously inject a high-concentration drag-reducing agent solution into the circulating pool until it reaches the set drag-reducing concentration range;

[0029] c. Run the gas pumping liquid ring vacuum pump, and use the polymer drag reducer solution as the working mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com