Fuel pump module

A fuel pump module and fuel pump technology, applied to liquid fuel feeders, engine components, machines/engines, etc., can solve the problems of rising manufacturing costs, time and labor, and achieve simplified structure, reduced manufacturing processes, and reduced The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

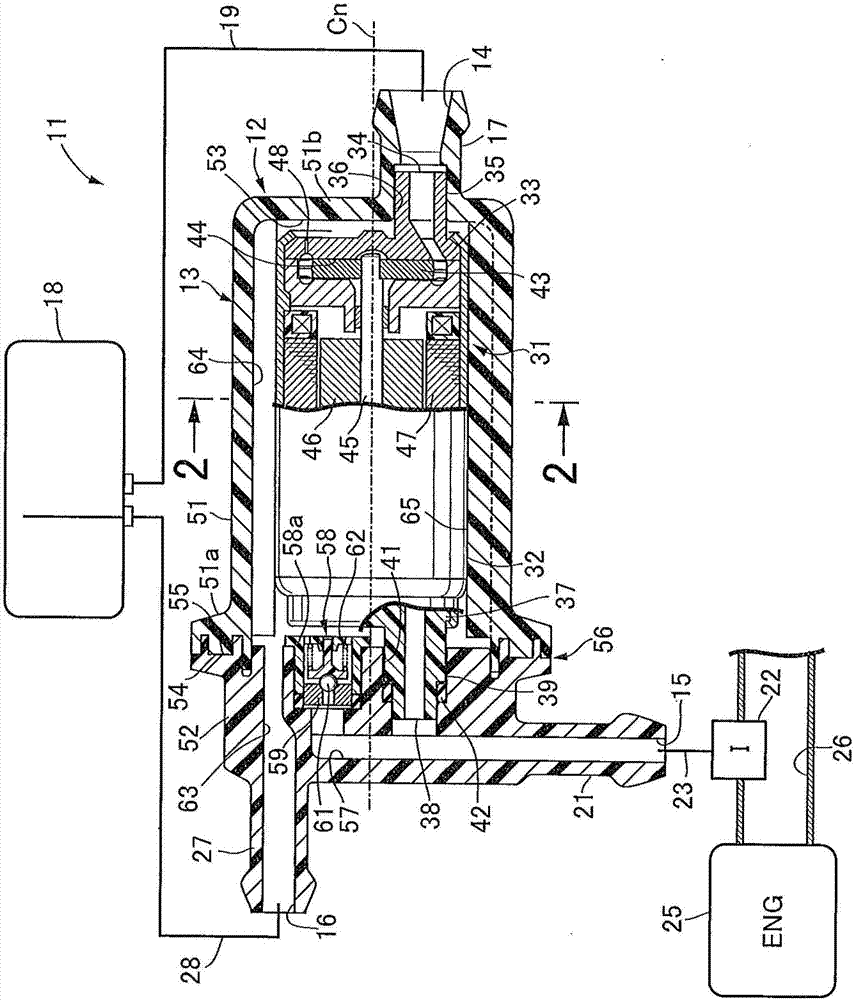

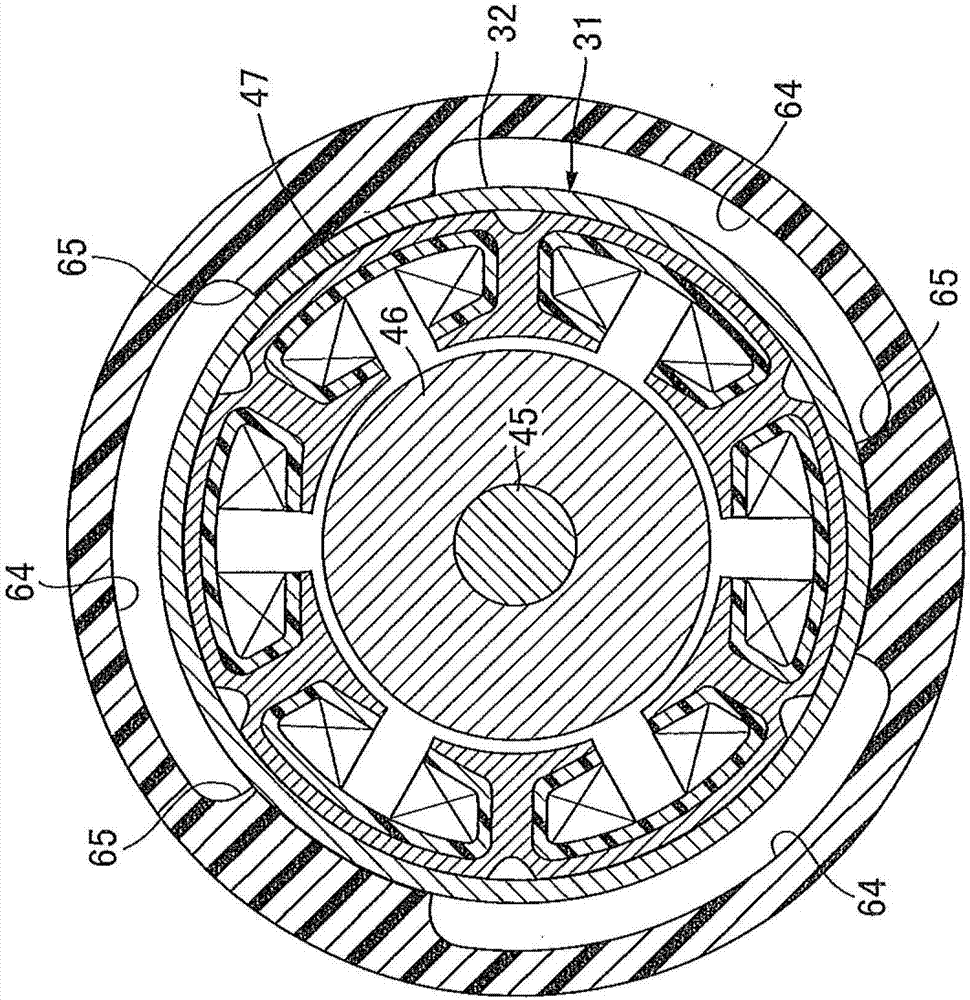

[0025] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

[0026] figure 1 The overall configuration of the vehicle fuel supply system 11 is schematically shown. The fuel supply system 11 has a fuel pump module 12 according to one embodiment of the present invention. The pump housing 13 of the fuel pump module 12 is formed in a cylindrical shape with a central axis Cn. An inlet 14 is defined at one end in the axial direction of the cylinder. An outlet 15 and a return port 16 are divided at the other end in the axial direction of the cylinder. The inlet 14 is formed by a pipe connection 17 . A fuel pipe 19 connected to a fuel tank 18 is combined with a pipe joint 17 . The outlet 15 is likewise formed by a pipe connection 21 . For example, a fuel pipe 23 connected to a fuel injection device 22 is coupled to the pipe joint 21 . The fuel injection device 22 faces an intake passage 26 connected to an intake passage of, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com