Multi-angle drilling device for motor production

A drilling device and multi-angle technology, applied in the direction of electromechanical devices, feeding devices, boring/drilling, etc., can solve the problems of increasing production steps and reducing production efficiency, and achieve the effect of ensuring production efficiency and reducing production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

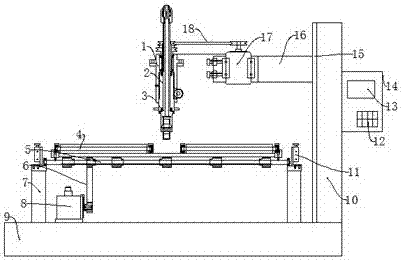

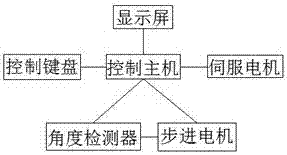

[0020] Such as Figure 1-Figure 3 As shown, a multi-angle drilling device for motor production, including a base 9, a fixed frame 7, a reinforcement plate 10 and a control box 14, the base 9 is provided with a fixed frame 7, and the fixed frame 7 is used to support and fix the rotating shaft 5 and an angle detector 11, the fixed mount 7 is provided with an angle detector 11, the angle detector 11 is used to obtain the angle value of the rotation of the rotating shaft 5 in real time, the fixed mount 7 is provided with a stepping motor 8, and the stepping motor 8 It is used to drive the transmission gear pair 6 to move. The end of the stepping motor 8 is provided with a transmission gear pair 6. The transmission gear pair 6 is used to drive the rotating shaft 5 to rotate. The end of the transmission gear pair 6 is provided with a rotating shaft 5. The rotating shaft 5 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com