Three-freedom degree positioning device for ray detection on airplane structural component and detection method

A technology for aircraft structural parts and positioning devices, applied in the direction of material analysis using radiation, etc., can solve problems such as poor repeatability, inaccurate positioning, and inconsistent angles, and achieve the effects of improving detection accuracy, meeting detection requirements, and facilitating adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

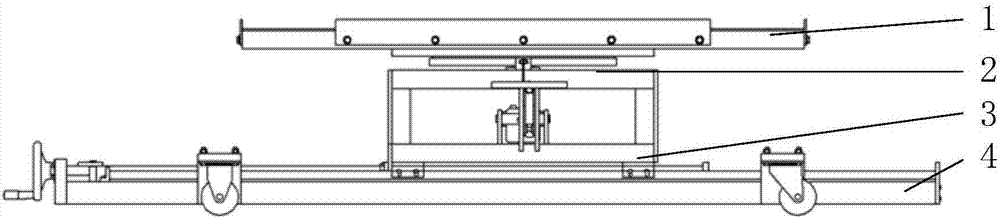

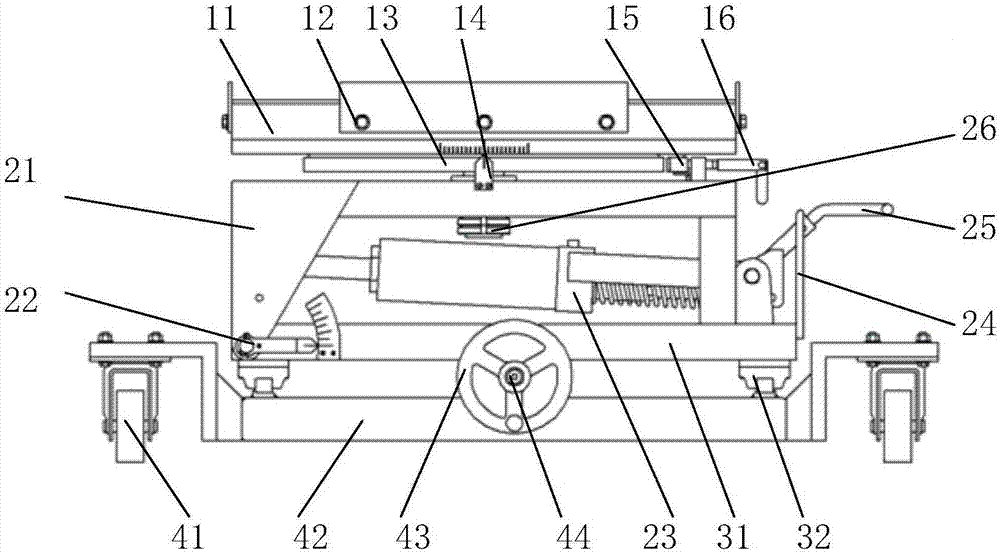

[0022] Referring to the accompanying drawings, a three-degree-of-freedom positioning device for radiographic inspection of aircraft structural parts includes a rotating frame 1 for placing aircraft structural parts, which is carried on a pitching frame 2 through a support bearing 14, and the pitching frame 2 is carried on a sliding frame 3 , the sliding frame 3 is carried on the bottom frame 4 through the support plate 32 .

[0023] The rotating frame 1 is composed of a support plate 11 , a blocking plate 12 and a rotating plate 13 . Place the aircraft castings on the support plate 11, restrain the castings from slipping through the blocking plate 12, adjust the angle of the rotating frame through the rotating plate 13, determine the angle of the rotating frame through the angle scale 14 in the pitching frame 2, and determine the angle of the rotating frame by rotating the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com