A method of treating ddnp wastewater by using the remaining heat of the cement rotary kiln

A cement rotary kiln and waste water technology, applied in the field of industrial explosives production, can solve the problems of high chroma, high pollutant toxicity, high chemical oxygen demand, etc., and achieve the effects of cost reduction, huge social benefit, and low cost of technical transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

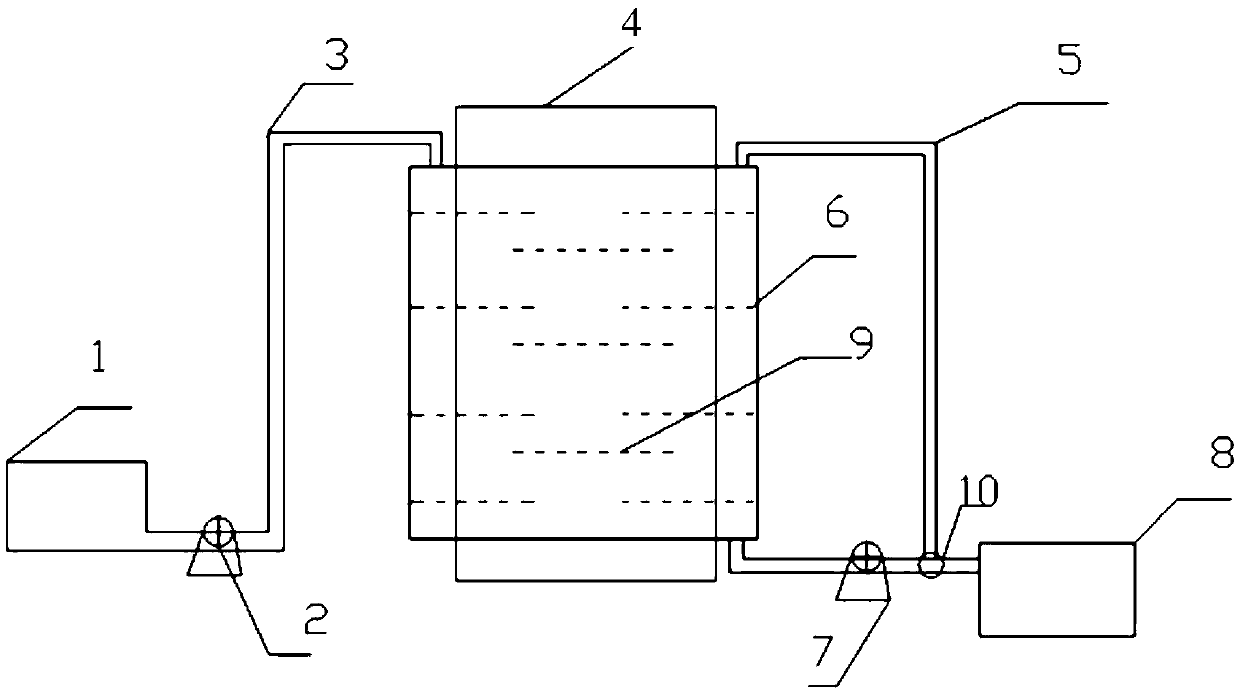

[0019] Attached below figure 1 The present invention will be further described in detail with specific embodiments. as the picture shows:

[0020] 1. Treat the DDNP wastewater collected during the detonator production process with dilute hydrochloric acid or sodium bicarbonate to a pH of 6.5-7.0. Use tank trucks to transport to the DDNP wastewater collection pool or storage tank at the cement production site for use.

[0021] 2. DDNP waste water is pumped 1000Kg to the upper part of the waste heat treatment device of the cement rotary kiln. The waste water is from the upper part due to gravity from top to bottom. Since the device is closely attached to the cement rotary kiln, the waste heat of the cement rotary kiln is about 1000 ℃.

[0022] 3. The DDNP wastewater pumped to the waste heat treatment device of the cement rotary kiln is heated through the device cycle. The cycle time is 30 minutes, and the waste liquid concentration is detected through the discharge port. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com