Hoisting tool for variable pitch component of wind power generator

A technology for wind turbines and tooling, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of difficult assembly, slow disassembly and assembly of spreaders, low assembly efficiency, etc., and achieves strong installation stability, enhanced connection force, Strong safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

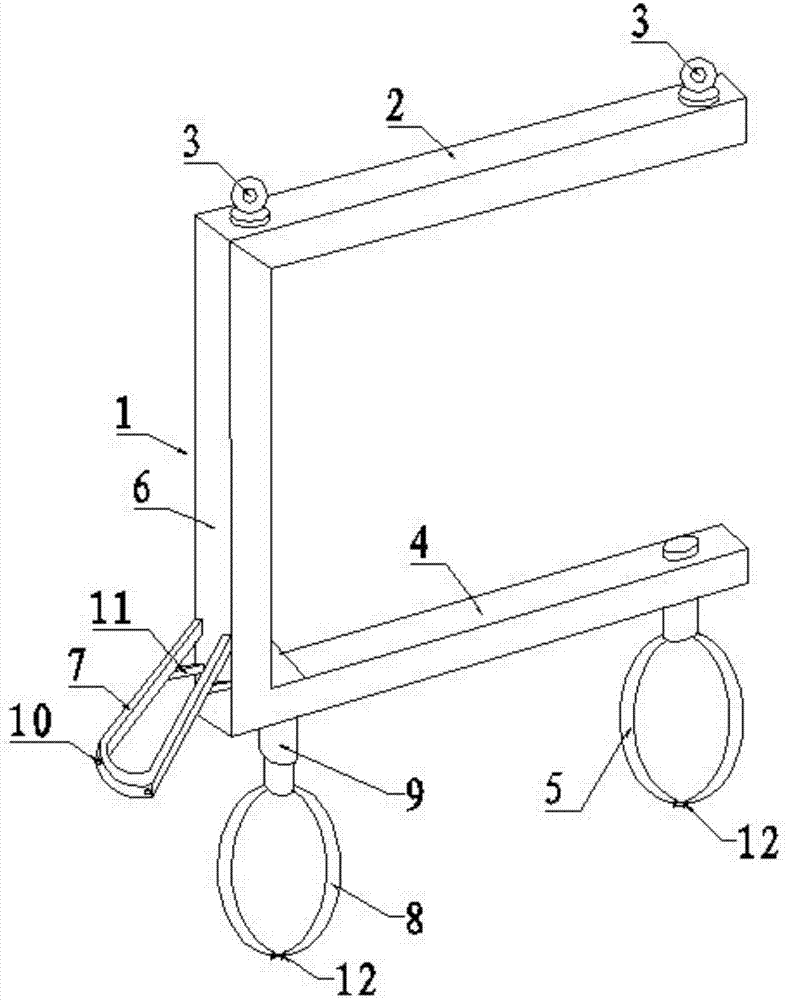

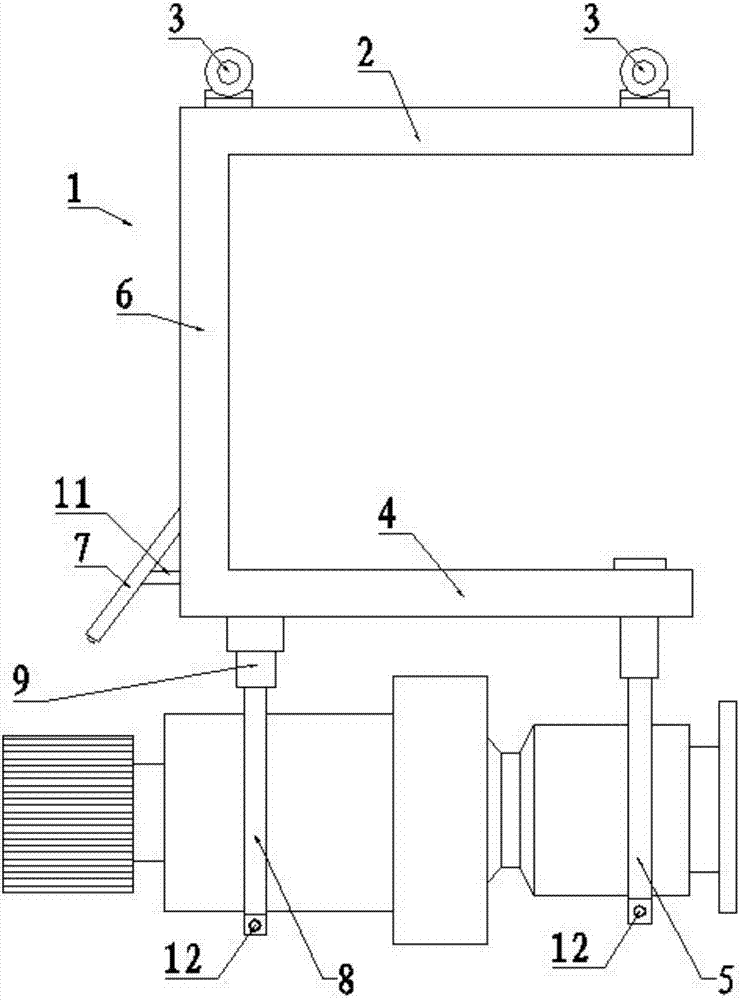

[0024] A hoisting tool for the pitch assembly of a wind turbine in this embodiment includes a C-shaped bracket 1, a lifting lug 3 is provided on the upper cross bar 2 of the C-shaped bracket 1, and a fixing card is provided on the lower cross bar 4 of the C-shaped bracket 1 The hoop 5 and the angle positioning tool, the lower end of the vertical rod 6 of the C-type bracket 1 is provided with a handle 7; the angle positioning tool includes a positioning clamp 8 and a hydraulic jack 9 from bottom to top. The fixed end of the hydraulic jack 9 is fixed on the lower cross bar 4 The left end and the telescopic end are fixedly connected to the upper end of the positioning clamp 8. The fixed clamp 5 is fixed on the right end of the lower crossbar 4; the surface of the grip part of the handle 7 is provided with non-slip friction patterns, and both ends of the grip part are provided with ejector control buttons 10; The angle between 7 and the vertical rod 6 is an acute angle; the handle 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com