Wheel-track composite type chassis structure

A wheel-track composite and tracked chassis technology, applied in the field of robots, can solve the problems of inability to achieve omnidirectional movement, slow switching speed, poor flexibility, etc., and achieve the effects of simple structure, easy replacement of parts, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

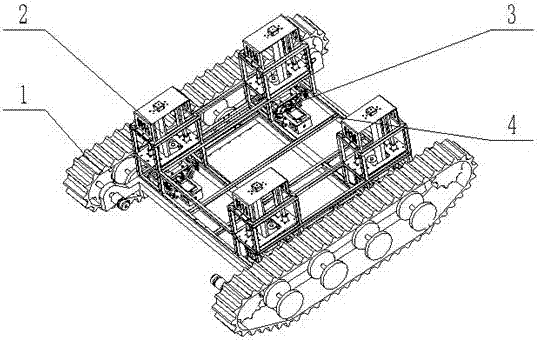

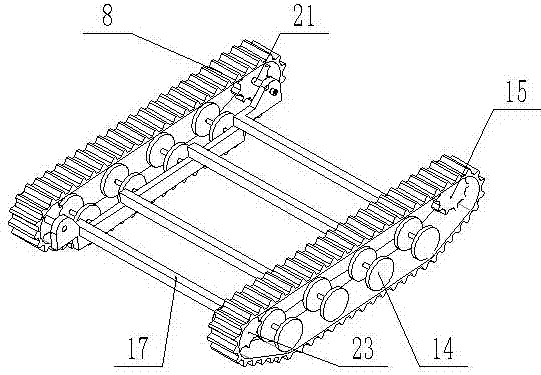

[0021] combine Figure 1~2 , the present invention proposes a wheel-track composite chassis structure, which can switch the chassis moving mechanism, including a crawler chassis 1, four electric push rod lifting mechanisms 2, four mecanum wheel moving mechanisms 3 and an omni-directional moving mechanism Platform frame 4, the omni-directional mobile platform frame 4 is fixed on the crawler chassis 1 by screws, the tops of the push rods of the four electric push rod lifting mechanisms 2 are respectively fixed on the omni-directional mobile platform frame 4 by bolts, and the four McNair The Mecanum wheel moving mechanism 3 is fixedly connected with the four electric push rod elevating mechanisms 2 respectively by bolts, and the Mecanum wheel moving mechanism 3 contacts and leaves the ground through the extension and contraction of the electric push rods.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com