Intelligent switching double-spray-head 3D printer

A 3D printer and intelligent switching technology, applied in the field of 3D printing, can solve the problems of reducing the freedom of movement of the printing nozzle, restricting the intelligent development of the printer, and complicating the filling circuit of the printing nozzle, so as to achieve the effect of ensuring printing efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

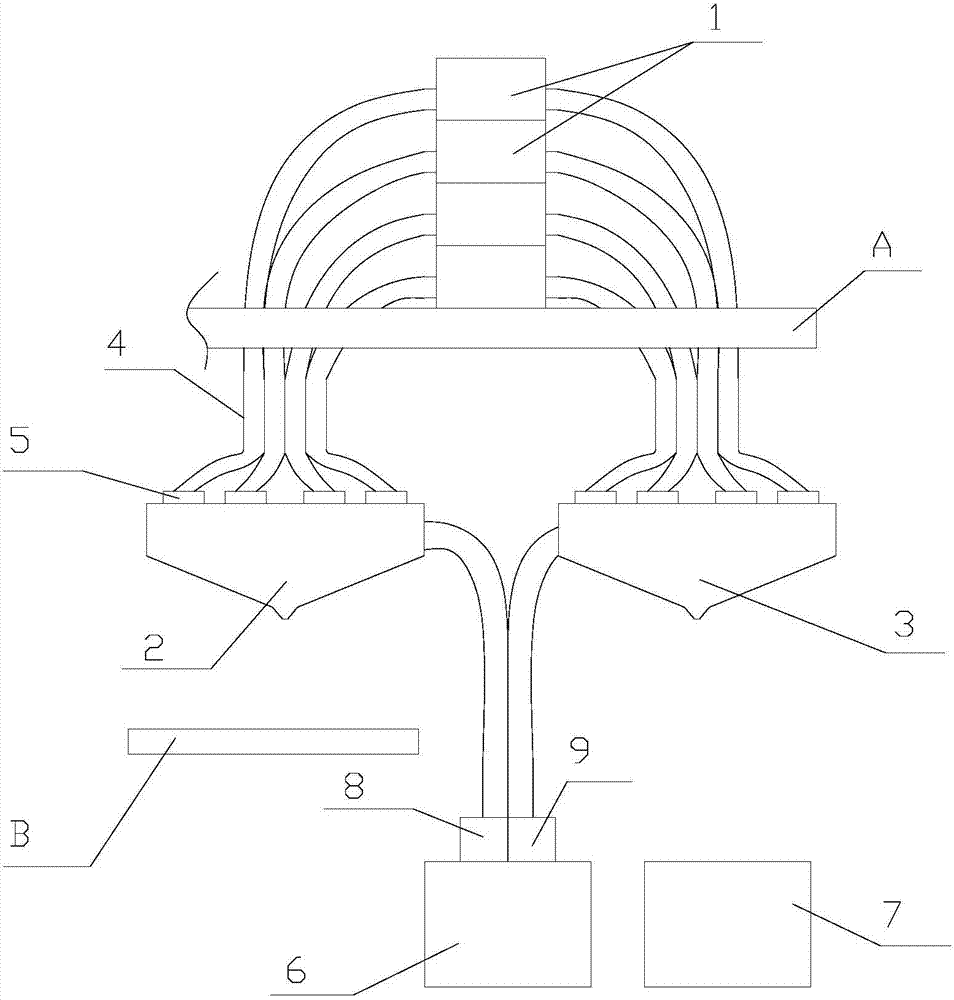

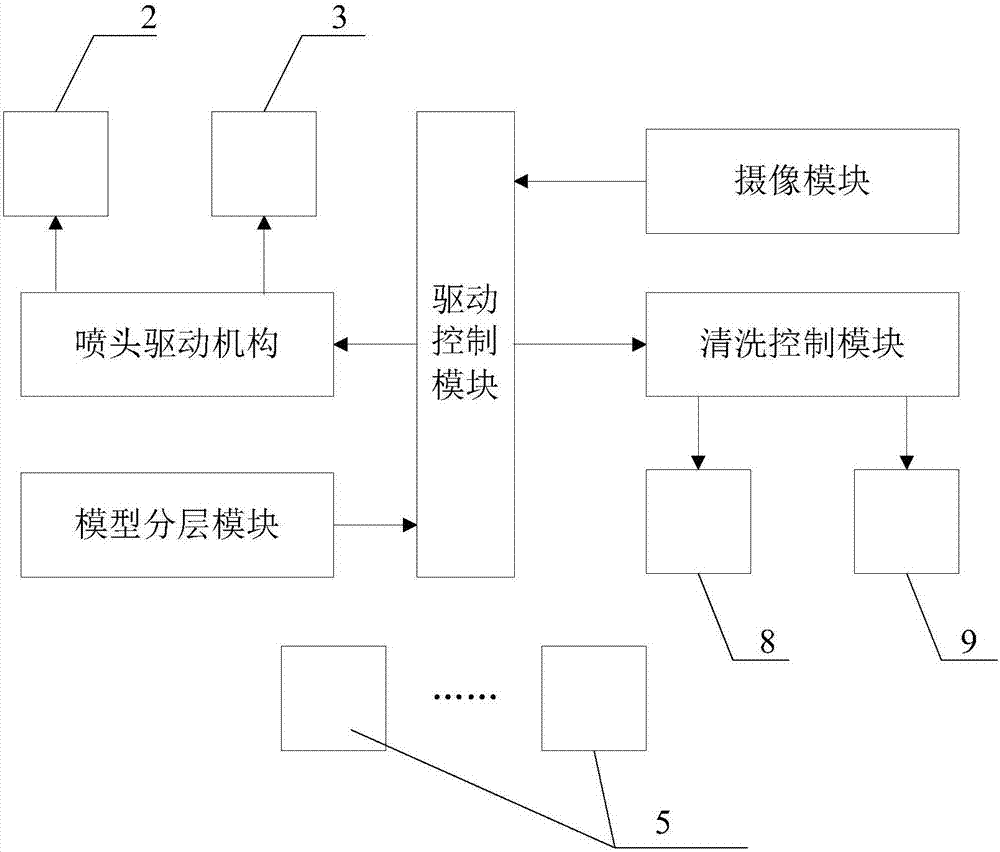

[0020] refer to figure 1 , figure 2 , an intelligent switching dual-jet 3D printer proposed by the present invention, including: a support frame A, a plurality of raw material storage tanks 1, a first nozzle 2, a second nozzle 3, a tray B, a cleaning water tank 6, a recycling water tank 7, the first A cleaning pump 8, a second cleaning pump 9, a nozzle driving mechanism, a model layering module, a camera module, a driving control module and a cleaning control module.

[0021] The first nozzle 2 is respectively connected to each raw material storage tank 1 through a plurality of feeding pipes, the second nozzle 3 is connected to each raw material storage tank 1 through a plurality of feeding pipes 4, and each feeding pipe is provided with a shut-off valve 5, The raw material storage tank 1 is installed above the first spray head 2 and the second spray head 3 . The raw material storage tank 1 fills the first nozzle 2 or the second nozzle 3 through the feeding pipe 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com